Welcome to the Industrial Automation website!

Product

Article

NameDescriptionContent

BENTLY 1900/65A General Purpose Equipment Monitor

The 1900/65A General Purpose Equipment Monitor is designed to continuously monitor and protect equipment that is used in a variety of applications and industries. The monitor’s low cost makes it an ideal solution for general purpose machines and processes that can benefit from continuous monitoring and protection.

BENTLY 1900/65A General Purpose Equipment Monitor

Description

The 1900/65A General Purpose Equipment Monitor is designed to continuously monitor and protect equipment that is used in a variety of applications and industries. The monitor’s low cost makes it an ideal solution for general purpose machines and processes that can benefit from continuous monitoring and protection.

Inputs

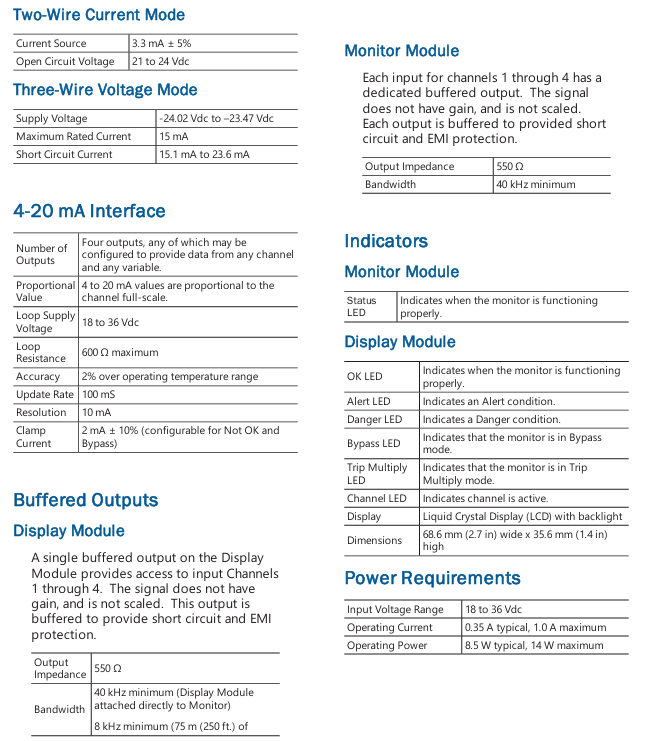

The 1900/65A provides four transducer inputs and four temperature inputs. Software can configure each transducer input to support 2- and 3-wire accelerometers, velocity sensors or proximity sensors. Each temperature input supports Type E, J, K, and T thermocouples, and 2- or 3-wire RTDs.

Outputs

The 1900/65A provides six relay outputs, four 4-20 mA recorder outputs, and a dedicated buffered output. The user can use the 1900 Configuration software to configure the relay contacts to open or close according to the OK, Alert and

Danger statuses of any channel or combination of channels, and to provide data from any variable from any channel on any recorder output. The dedicated buffer output can provide the signal for each transducer input.

A Modbus Gateway option allows the monitor to provide static variables, statuses, event list, time and date information directly to any Modbus client, including Distributed Control Systems (DCSs), Supervisory Control and Data Acquisition (SCADA) systems, Programmable Logic Controllers (PLCs), or System 1 software. The monitor uses an internal counter and a Modbus client/master time reference to generate time and date information. Users can upgrade monitors without the Modbus Gateway by ordering the 1900/01 Communications Upgrade (see the Ordering Information section). The 1900/65A supports Modbus communications via Ethernet and a software-configurable RS232/485 serial port.

Configuration

The user defines monitor operation and the Modbus Gateway register map by using

software running on a laptop or PC to create a configuration file and download the file to the monitor through the built-in Ethernet connection. The 1900/65A permanently stores configuration information in non-volatile memory, and can upload this information to the PC for changes.

Display Module

The 1900/65A supports an optional display/keypad to view channel information or

make minor configuration changes. This allows the 1900/65A to operate as a stand-alone package. If desired, the user can mount the display up to 75 metres (250 feet) from the Monitor Module.

Specifications

Inputs

Transducer Inputs

Users can configure Channels 1 through 4 to accept input from acceleration, velocity or displacement transducers.

Transducer Channel Types

Channel Types define the functionality for processing that will be applied to an input signal and the kind of variables or measurement values that will be derived from this input. Channel Types also define the kind of sensor that must be used. Transducer Channel Types include:

Acceleration or Reciprocating Acceleration

Velocity or Reciprocating Velocity

Radial Vibration (shaft vibration)

Thrust (shaft axial displacement)

Position

Speed

Acceleration and Reciprocating Acceleration Channel Types

The Acceleration Channel Type and Reciprocating Acceleration Channel Type support two- and three-wire acceleration sensors. The Reciprocating Acceleration

channel type has timed OK channel defeat disabled.

Acceleration Variables and Reciprocating Acceleration Variables

Acceleration Variables and Reciprocating Acceleration Variables are filtered and

processed measurements from raw transducer signals. The Acceleration

Channel Type and Reciprocating Acceleration Channel Type continuously processes up to four variables per channel.

Vibration:Up to three bandpass filtered amplitude measurements.

Acceleration :Users can apply the acceleration enveloping algorithm to one Acceleration or Reciprocating Acceleration Variable.

Enveloping:Bias Voltage Users may assign the value of the transducer bias voltage to any of the variables.

Filters

Vibration Variable: 0.5 Hz – 25 kHz configurable 4-pole high pass, 4-pole low-pass

Enveloping High-Pass:25 Hz to 5 kHz, configurable 4-pole

Enveloping Low-Pass:125 Hz to 25 kHz, configurable 2-pole

Enveloped Variable High Pass: 0.1 Hz min., but greater than Enveloped Variable low-pass 2-pole

Enveloped Variable Low Pass:Greater than Enveloped Variable high-pass and less than Enveloping high-pass 4-pole

Bias Filter:0.01 Hz 1-pole low-pass

OK Filter:2.4 kHz 1-pole low-pass

Full Scale Range

Vibration:20 to 500 m/s2 (2 to 50 g) peak and RMS

Enveloped:20 to 500 m/s2 (2 to 50 g) peak and RMS

Integrated:10 to 100 mm/s (0.4 to 4 in/s) peak and RMS

Bias Voltage:-24 V

Accuracy

Vibration Variables: ±1% of full scale range

Input Impedance

3-wire Voltage Mode;10 kΩ

Velocity and Reciprocating Velocity Channel Type

The Velocity Channel Type and Reciprocating Velocity Channel Type support two-wire and three-wire piezo velocity sensors.

Velocity Variables and Reciprocating Velocity Variables

Velocity Variables and Reciprocating Velocity Variables are filtered and processed measurements from raw transducer signals. The Velocity Channel Type and Reciprocating Velocity Channel Type support up to four continuously calculated variables per channel.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands

229

+86-153-9626-8993

WeChat

Contact

Whatsapp

After years of experience, it has developed into a group enterprise entity integrating equipment, industrial, chemical, petroleum equipment, electricity and other products trade and services.

KONG JIANG

Product

Copyright © 2023 KongJiang Group All Rights Reserved .