We will further strengthen work safety in mines

7. Accelerating the upgrading of mines. Promote the mechanization and upgrading of small and medium-sized mines and the automation and intelligent upgrading of large mines, accelerate the intelligent construction of mines with serious disasters and high altitudes, and create a number of automated and intelligent benchmark mines. Underground mines shall establish personnel positioning, safety monitoring, communication, pressure and wind self-rescue and water supply rescue systems. The filling mining method should be adopted in principle in the newly built, renovated and expanded metal and non-metal underground mines. Small and medium-sized metal and non-metal underground mines shall not have more than 4 production levels of mining at the same time. Tailings ponds should establish an online safety monitoring system, and new fourth and fifth grade small tailings ponds should be built in one time.

8. Improving the ability to support scientific and technological innovation Strengthening the construction of science and technology support systems for mine safety. Strengthen research on the prevention and treatment of major mining disasters, organize major key technology research. Promote the development and application of mine information technology, intelligent equipment and robots. A number of major science and technology projects related to mine safety were implemented. To study and promote the construction of a national key laboratory in the field of mine safety.

3. Forestall and defuse major security risks

(9) Improve the safety management system in mines. Mining enterprises should improve the safety production standardization management system with safety risk classification control and hidden danger investigation and management dual prevention mechanism as the core. Strictly carry out risk identification and assessment and implement hierarchical control, regularly carry out full coverage of hidden danger investigation and management, establish a list of hidden risk accounts, and implement closed-loop management. Mine safety supervision and supervision departments at all levels shall promote enterprises to effectively improve the quality of risk and hidden danger investigation and rectification, establish a major hidden danger management and supervision system, track supervision before major hidden dangers are eliminated, and supervise the rectification and cancellation. Where major hidden dangers still exist or accidents occur due to inadequate investigation and rectification, enterprises and relevant responsible persons shall be investigated for their responsibilities according to law.

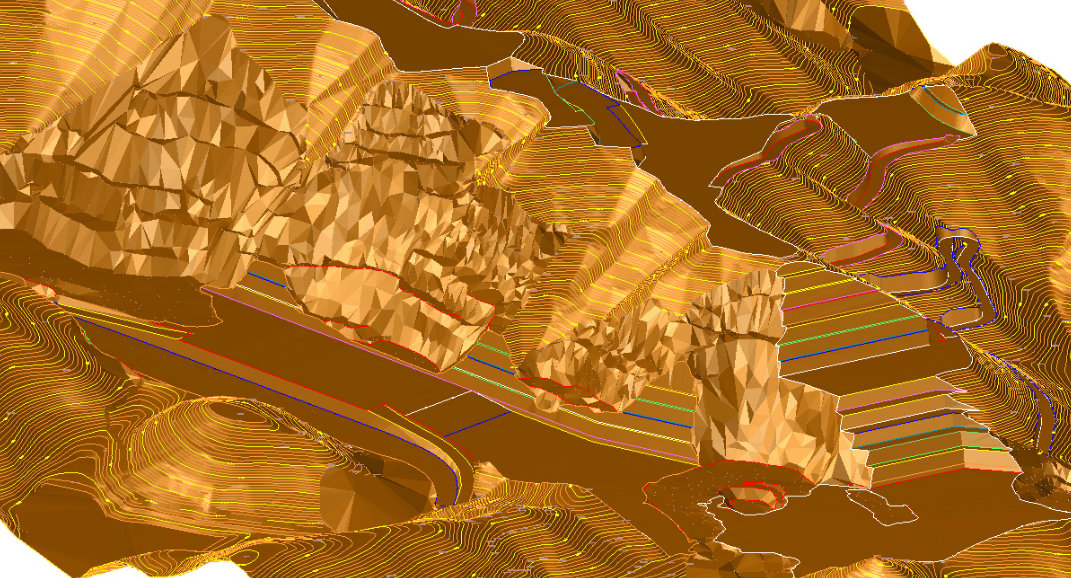

10. Strengthening disaster management. Mining enterprises shall identify hidden disaster factors and implement regional management and advanced treatment of major disasters such as coal and gas outburst, rock burst and water damage. The evaluation of coal mine disaster levels shall be included in the scope of safety testing and inspection, and the evaluation results shall be publicized in a timely manner. Standardize the management and verification of coal mine production capacity. Where the slope height of the stope and dump of a metal and non-metal open-pit mine is greater than 100 meters, the stability analysis of the slope shall be carried out year by year. Where the volume of the goaf of a metal and non-metal underground mine exceeds the prescribed amount, a special stability assessment shall be carried out in a timely manner. The quality inspection of the flood discharge structure of the tailings pond shall be carried out once every three years.

(11) Strict safety management of equipment and facilities. We will improve the review, issuance and supervision mechanism of safety signs for special equipment in underground mines. Regular safety and reliability inspection shall be carried out on in-use equipment and facilities that have obtained safety marks for underground special equipment. Establish a intelligent supervision platform for the whole life cycle of mining safety equipment, and implement a safety responsibility system for mining equipment.

(12) Standardize the management of non-coal mine outsourcing projects. Non-coal mining enterprises are uniformly responsible for the safety management of outsourcing engineering construction units. It is strictly prohibited to outsource special blasting operations in metal and non-metal underground mines. The number of contracting units for excavation projects of metal and non-metal underground infrastructure construction shall not exceed 3. The number of contracting units for mining projects of large and medium-sized metal and non-metal underground production mines shall not exceed 2, and the number of contracting units for mining projects of small metal and non-metal underground production mines shall not exceed 1, and contracting units shall not subcontract or subcontract mining projects and blasting operations. The contractor shall dispatch the project leader, technical personnel and special operation personnel to the project department; The person in charge of the project and the technical personnel shall have a secondary school degree or above in mining related majors or a professional title of intermediate or above, and shall not take part-time jobs in other mines. Strive to the end of 2025, production mines to establish their own mining (stripping) construction team or entrust with the appropriate conditions of the overall management of enterprises.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands