Born to the mine, Huawei makes the construction of smart mines reach the realm of no one

Hidden skills may be the only way to do deep industry

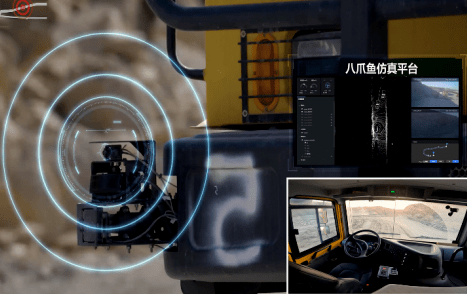

In addition to the vehicle-road-cloud architecture, we believe that its ability to complete the training of the perceptual model based on a small sample amount of data will be the key to its ability to understand the scene and continue to play the technology.

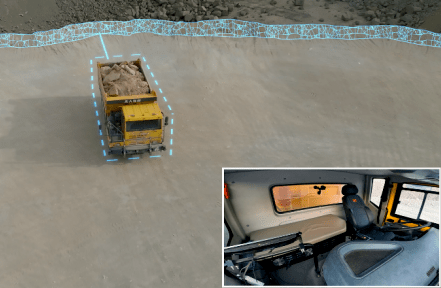

Huawei's sensing algorithm has strong adaptability to the environment, improving the reliability and versatility of technology in different operating environments. This greatly reduces the requirements for data collection and the difficulty of algorithm training, improves the ability of accurate target detection in a sand and dust environment, and provides protection for safe driving with long-distance vehicle identification, retaining wall boundary and highly accurate identification, ground relief detection, soil gravel or small stone detection, etc.

Having this ability actually means that the landing flexibility of Huawei's solution is higher, that is to say, it has the ability of commercial replication.

Open cooperation, build a full stack ecology on top of full stack capability

There is no denying that unmanned vehicles need to become a part of smart mines and serve the overall construction of smart mines. In addition to the capability of driverless "car-road-cloud" scenarios in mines, Huawei also has full-stack technical capabilities for smart mine integration such as mining Hong (mine Internet platform), smart park, digital cloud platform base, 5G, Pangu model (AI), etc., which can consider the overall development needs of mines and pull through various informatization automation systems in mines. Avoid duplicative digital building investments.

However, this does not mean that Huawei should do all the work. In fact, full-stack capability is precisely for full-stack ecological cooperation. Attaches great importance to industry cooperation and co-construction. Not only that, in the practice of landing in the field of mine autonomous driving, Huawei has also actively opened its own capabilities to industry companies. At present, partners such as Easy Control Intelligent Driving, Hibo Intelligent Energy, Xidi Intelligent Driving, Huituo, Tage Zhixing, and Bolai Technology have applied Huawei's hardware products and customized technologies.

3 How is the construction of open-pit intelligent mine Huawei?

In October 2021, Huawei began to deploy the mine unmanned deployment system in Xingsheng open-pit Coal Mine in Xinjiang (with a production capacity of 23 million tons/year). In the process of promoting the project, Huawei deeply integrated artificial intelligence, cloud computing, vehicle networking, intelligent driving, high-precision map and other technologies with modern coal mining, realized the continuous operation of the full process of mining, transportation and drainage of automated mining trucks in open pit mines, and gradually promoted the commercial deployment of more than 70 vehicles within three years.

Efficient and safe, mine driverless equal manual operation

In the test of the Jiangna project, through a one-month continuous test of the actual production environment, the operational efficiency of "unmanned" and "manned" was compared. The results show that the actual operation time of unmanned driving can reach 22 hours per day, and the continuous operation of the whole process without safety personnel, and its comprehensive efficiency has reached more than 90% of that of manual driving, and the overall effect is almost comparable to that of manual driving. In the near future, with the improvement of system performance, more data accumulation and more mature algorithm training will push unmanned driving gradually beyond the human level.

In addition, in terms of safety, mine driverless can provide higher safety and reliability. In the process of solving multi-vehicle right-of-way conflicts, Huawei Vehicle Cloud collaborative solution can avoid path conflicts and multi-vehicle deadlocks at the planning level based on the "God perspective", and realize global situation awareness through roadside facilities, improve blind area obstacle detection capabilities, and greatly improve vehicle safety and reliability.

Build the "strongest brain" in the cloud, and see real efforts in details

The engineering process of the open-pit mine scene is intelligent, and the most tested is not the standardized process, but the conversion of the joint junction point of mining, transportation and drainage. The adaptability of Huawei's mine driverless solution is well reflected in the details of these scenarios.

The first is the ability to perceive the unique scene of the mine. Based on the powerful perception model, the car can accurately detect small targets such as falling rocks in the dust environment; Through precise semantic segmentation, the car can distinguish the boundary between the mine retaining wall and the ground well, as well as the irregular and dynamically changing production surface. Even for the objects that need to be identified, such as mine sprinklers and refueling trucks with few samples, it can ensure that the trained model has a good generalization ability.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands