Mine equipment operation safety risk points and prevention and control

④ No one is allowed in the diamond beaded rope operation area. Non-equipment operators are strictly forbidden to enter the diamond beaded rope operation area. When the equipment operator enters the diamond beaded rope operating radius area, the diamond beaded rope should be suspended before entering the area.

⑤ The diamond beaded rope operation area should be hung to prohibit others from entering the warning sign. Because there is a huge safety risk when the diamond beaded rope breaks. Therefore, the stone mine should set up a safety warning that prohibits others from entering the area of diamond beading rope operation, and remind non-operators that people are strictly prohibited.

⑥ Diamond beaded rope operation safety precautions. Diamond beaded rope should start at a low speed and gradually increase the speed into normal operation. Diamond beaded rope operation operators should not stay away from the working area, always observe the operation of the equipment and diamond beaded rope saw, timely find the abnormal operation of the equipment and diamond beaded rope, and timely deal with it. Diamond beads should be kept away from it when running, to prevent the damage caused by the sudden break of diamond beads, the operator should strengthen the inspection of diamond beads and joints on the surface of the diamond string rope, when the beads on the diamond string string burst and the steel wire is about to break, the beads and steel wire should be cut off in time.

7 Diamond beaded rope working area around the installation of protective guardrail. Diamond beaded saw is prone to broken rope injury accident, set protective fence around the diamond beaded rope operation area: diamond beaded rope above the installation of protective belt to prevent broken rope injury.

(5) Mine installation operation safety risk points and prevention and control

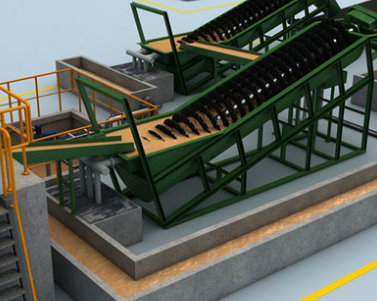

Mining machine is an important loading and unloading and transferring equipment for stone mines, which is responsible for the transfer of raw materials and plates mined from mines. There are more safety accidents caused by forkloading, and there are also many adverse factors in production. It is an important work in the safety production management of mining enterprises and an important aspect of safety risk control.

① Job skill requirements. Mine fork installation operators should be issued by the state of the post operators. Unlicensed personnel are strictly prohibited from operating such equipment. Operators engaged in mining fork installation should have more than one year of work experience. Because the working conditions and environment of stone mines determine that the personnel engaged in such work should have richer work experience.

② Safety requirements during operation. The operation should strictly abide by the provisions of the post operation system, the fork installation and operation should focus on careful driving, and always tighten the string of safe production. It is strictly forbidden to overload the car, which is the biggest safety risk in the fork loading operation. Compliance with the provisions of this safety system, and loading safety accidents can be greatly reduced, or even do not appear.

(3) Prevention and control of security risks. The key to prevent and control the safety risk of reloading is to strengthen the safety management of reloading and improve the safety risk awareness of the operators and employees. Strengthen the daily maintenance and maintenance of forklifts; To increase the punishment of illegal operators, with strict system management fork loading operators; Create a spacious and neat working environment for forklifts.

(6) Mine motor transport safety risks and prevention and control

① Job skill requirements. Mine motor transport drivers should hold the corresponding driving license for the vehicle they are driving. Large dump trucks are best to have one year of experience.

② Safety requirements during operation. When loading the vehicle, the driver or command personnel can signal the transport vehicle to drive into the loading site. It is forbidden to start the vehicle by sliding, and it is forbidden to glide in neutral when driving downhill. When parking on a ramp, the driver cannot leave and must use the parking brake and take safety measures. The motor vehicle should drive at medium speed on the mining road, and the speed limit should be limited in sharp bends, steep slopes and dangerous areas. When the visibility is affected by fog and smoke, the front yellow light and sign light should be turned on, and the distance between the front and rear workshops should not be less than 30m. When the road is slippery in snow and snow and rainy season, there should be anti-skid measures and slow down. The distance between front and rear vehicles shall not be less than 40m; It is forbidden to turn sharply, brake sharply, overtake or drag other vehicles, and the car should follow the command when entering the dumping site. After unloading, the tipper should drop the tipper in time, be sure to make sure that the tipper is well dropped before moving the car, and strictly prevent the tipper from erecting and damaging high-altitude lines and pipelines and other facilities. The dumper is not allowed to approach when the tipper is rising and falling, and the operator should be placed in neutral position after unloading. Prevent accidents caused by tipping bucket automatically rising when driving. The dump truck is strictly prohibited to carry flammable and explosive materials, and the outdoor platform, foot board and bucket are not allowed to carry people. Do not lift the bucket in operation. It is necessary to strengthen the inspection and maintenance of motor vehicles to ensure that the front and rear lights of motor vehicles are normal and the brakes are sensitive and reliable.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands