ABB Relion ® 615 series RED615 line differential protection and control device

Integrated protection function: with "line differential protection" as the core main protection, while integrating backup protection such as overcurrent, ground fault, circuit breaker failure, etc., to meet the requirements of modular protection;

Standardized communication: Deeply compliant with the IEC 61850 standard, supporting GOOSE messages (transmission delay ≤ 3ms), IEC 60870-5-103, Modbus ®、 DNP3 and other protocols, adapted for interconnection of substation automation systems;

Flexible configuration capability: Provides 3 standard configuration solutions, supports customizing signal logic through PCM600 tool, and adapts to different grounding methods (isolated neutral, resistance grounding, compensation grounding, direct grounding) of the power grid;

Full lifecycle support: Equipped with a complete documentation system (engineering, installation, debugging, operation and maintenance manuals), supporting local (LHMI) and remote (WHMI) operations, simplifying engineering and maintenance processes.

ABB Relion ® 615 series RED615 line differential protection and control device

Product basic positioning and core features

RED615 is ABB Relion ® The intelligent electronic device (IED) for line differential protection and control under the 615 series is designed specifically for public utilities and industrial power systems. Its core application is the protection and control of overhead lines and cable feeders, and it is suitable for ring and mesh power grids with or without distributed generation. Its core characteristics can be summarized as:

Integrated protection function: with "line differential protection" as the core main protection, while integrating backup protection such as overcurrent, ground fault, circuit breaker failure, etc., to meet the requirements of modular protection;

Standardized communication: Deeply compliant with the IEC 61850 standard, supporting GOOSE messages (transmission delay ≤ 3ms), IEC 60870-5-103, Modbus ®、 DNP3 and other protocols, adapted for interconnection of substation automation systems;

Flexible configuration capability: Provides 3 standard configuration solutions, supports customizing signal logic through PCM600 tool, and adapts to different grounding methods (isolated neutral, resistance grounding, compensation grounding, direct grounding) of the power grid;

Full lifecycle support: Equipped with a complete documentation system (engineering, installation, debugging, operation and maintenance manuals), supporting local (LHMI) and remote (WHMI) operations, simplifying engineering and maintenance processes.

Document and symbol specifications

(1) Document system and audience

Document positioning: This document is the "Application Manual", focusing on functional application scenarios and parameter setting guidelines. It needs to be used in conjunction with other manuals (such as the "Engineering Manual" for tool operation and the "Installation Manual" for physical installation);

Target audience: Protection and control engineers with knowledge of power engineering and communication protocols, responsible for equipment planning, preliminary engineering, and on-site debugging;

Version history: The current version is version B (released in July 2009), corresponding to product version 2.0. Compared to version A (October 2008), it has added support for DNP3 protocol, standard configuration B/C, and WHMI disturbance record upload function.

(2) Security and document symbols

Symbol Type Meaning Application Scenarios

The electrical warning icon poses a risk of electric shock and involves chapters on power wiring and terminal operation

Warning icons may pose a chain risk of personal injury caused by equipment failure, such as power grid accidents due to protection failure

Please note that icons may cause device damage, software abnormalities, parameter configuration errors, improper wiring, and other scenarios

Information icon key operation prompt function activation conditions and default parameter description

Suggestions for optimizing icon engineering, such as CT selection techniques and communication networking solutions

(3) Functional coding specification

The functional identification adopts a combination of "IEC 61850 name+IEC symbol+IEC-ANSI number", for example:

Line differential protection: LNPLDF1 (IEC 61850), 3dI>L (IEC symbol), 87L (ANSI number);

Directional grounding fault protection: DEFLPDEF1 (IEC 61850), I ₀>→ (1) (IEC symbol), 67N-1 (1) (ANSI number).

Product hardware and operating interface

(1) Hardware structure

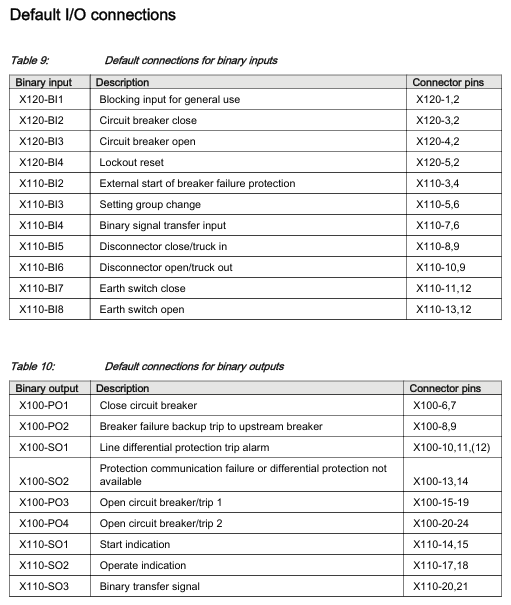

The RED615 hardware consists of a "plug-in unit+chassis", and the core plug-in modules and functions are as follows:

Plug in module slot ID core function key parameters

Auxiliary power supply/BO module X100 provides auxiliary power supply, output trip/signal contact power input: 48-250V DC/100-240V AC; Including 2 sets of PO contacts and 1 set of SO contacts

Binary I/O module X110 binary input/output with 8 BI and 4 SO contacts

Analog input/BI module X120 collects current/voltage signals, expands BI 3-channel phase current (1/5A), 1-channel zero sequence current (1/5A or 0.2/1A), and 1-channel zero sequence voltage (configuration B exclusive)

Optional BIO module X130 expansion I/O with 6 BI and 3 SO contacts

Communication module X000 protocol communication supports Ethernet (100BASE-TX), RS-485, and fiber optic (ST interface)

(2) Operation interface

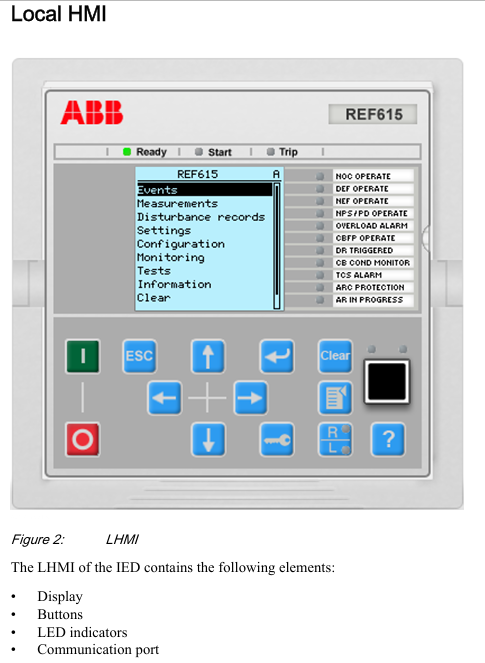

Local HMI (LHMI)

Display unit: LCD supports two character sizes (small characters: 5 rows x 20 columns; large characters: 4 rows x 8 columns), divided into four display areas: "title, icon, content, and scrollbar";

LED indicator lights: 3 fixed protection lights (Ready/Start/Trip)+11 programmable alarm lights (such as differential protection action, CT fault);

Key functions: navigation key (switching menu), control key (circuit breaker opening and closing), function key (alarm confirmation, reset, local/remote switching).

Web HMI(WHMI)

Access method: accessed through IE 7.0+browser, disabled by default, requires manual activation;

Core functions: parameter configuration, real-time measurement value viewing, disturbance record download, phasor diagram display, menu structure consistent with LHMI;

Access range: Local (connected to laptop via front-end RJ-45 port) or remote (via LAN/WAN).

(3) User Authorization

Four types of user permissions are preset, with authorization disabled by default (WHMI mandatory), and passwords can be changed by administrators:

Typical operations within the scope of username permissions

VIEWER read-only view of measurement values and alarm logs

OPEROTOR control and status switching, local/remote mode switching, alarm reset

ENGINEER configuration and testing modify parameters, clear disturbance records, enter testing mode

Administrator full permission to change password and restore factory settings

Core functions and standard configurations

(1) Three standard configuration schemes

RED615 provides three predefined configurations that cover different ground fault protection requirements, with the following core differences:

Configuration Type Core Protection Function Applicable Scenarios Key Modules

Configure A (line differential protection), including line differential protection (87L), three-phase overcurrent protection (50P/51P), negative sequence overcurrent protection (46), and circuit breaker failure protection (51BF), for cable feeders. In scenarios where ground fault protection is not required, there is no zero sequence voltage input and the CT synthesis of zero sequence current is relied upon

Configuration B (including directional grounding fault protection) Configuration A: All functions+directional grounding fault protection (67N), transient/intermittent grounding fault protection (67NIEF), automatic reclosing (79). For overhead lines/cable mixed lines, it is necessary to distinguish the fault direction of the power grid (such as multi power distribution network), including zero sequence voltage input (U ₀), and adapt to the compensation grounding system

Configuration C (including non directional grounding fault protection) Configuration A: All functions+non directional grounding fault protection (50N/51N), automatic reclosing (79), radiation type distribution network, no need to distinguish fault direction scenarios (such as single power supply feeders) rely on CT synthesized zero sequence current, no zero sequence voltage input

(2) Detailed explanation of key protection functions

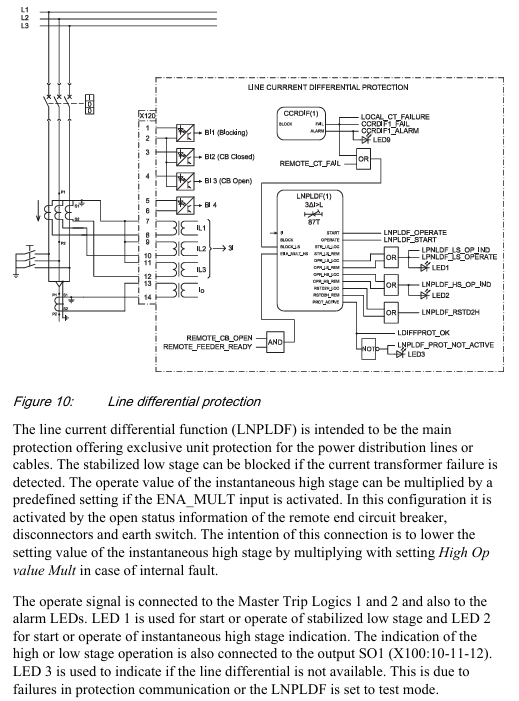

Line differential protection (LNPLDF1, 87L)

Core function: As the main protection, it realizes unit protection of the line and quickly cuts off internal faults;

Features: Contains stable low order (can be locked by CT fault detection) and instantaneous high order (can dynamically adjust the action value through remote circuit breaker status);

Communication dependency: It is necessary to establish protective communication with the remote IED, which will automatically lock in case of communication failure to avoid misoperation.

Earth fault protection

Directional (configuration B): Based on the phase of zero sequence current (I ₀) and zero sequence voltage (U ₀), the fault direction is determined, suitable for multi terminal power grids, divided into low order (sensitive section) and high order (fast section);

Non directional (configuration C): Based solely on zero sequence current amplitude action, suitable for single ended power grids, divided into low order, high-order, and instantaneous order.

Automatic reclosing (DARREC1, 79, configuration B/C optional)

Starting condition: triggered by protection action signals (such as overcurrent, ground fault);

Locking logic: The circuit breaker spring is not storing energy, the gas pressure is low, and it is locked when manually opening;

Status indication: LED5 is lit during the reclosing process, and an alarm is triggered when it fails.

Circuit breaker related protection and monitoring

Circuit breaker failure protection (CCBRBRF1, 51BF/51NBF): When the circuit breaker is not opened after the protection action, a trip command is sent to the upstream circuit breaker;

Trip Circuit Monitoring (TCSSCBR1/2, TCM): Monitor 2 sets of trip coil circuits, and lock the monitoring function when the circuit breaker is opened;

Circuit breaker status monitoring (SSCBR1, CBCM): Based on current and contact status, the mechanical characteristics of the circuit breaker are determined, and an alarm is triggered when there is an abnormality.

Communication and Networking

(1) Protocol support

Protocol type, functional scope, physical interface

IEC 61850 monitoring, control, parameter configuration, disturbance record upload (COMTRADE format), GOOSE message (trip level delay ≤ 3ms) Ethernet (RJ-45100BASE-TX)

IEC 60870-5-103 Protection signal upload, telemetry and remote signaling RS-485 or Ethernet

Modbus RTU/ASCII third-party device interconnection (such as PLC, SCADA) RS-485 or RS-232

DNP3 telemetry, remote signaling, remote control, supporting TCP/IP or serial Ethernet or RS-485

(2) Precautions for Communication Networking

GOOSE application: supports the highest performance level (transmission delay ≤ 3ms), meets the tripping requirements of distribution substations, and can simultaneously send events to 5 clients;

Client limitation: A single IED can support up to 5 concurrent clients. After PCM600 occupies 1, the remaining 4 can be allocated to other protocol clients;

Time synchronization: Line differential protection requires remote station time reference synchronization, which is recommended to be implemented through IEC 61850 or SNTP.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands