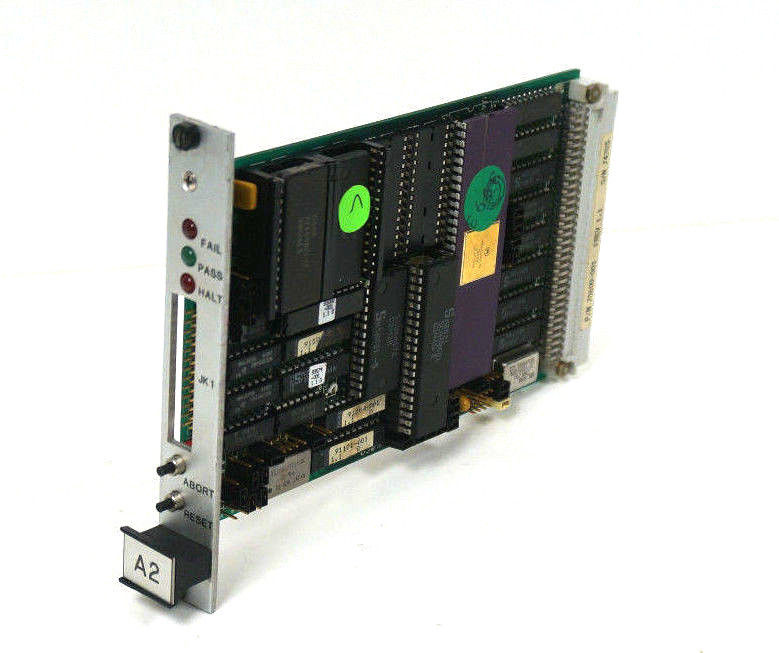

Xycom 89060B circuit board

Xycom 89060B circuit board

Product Overview

The Xycom 89060B circuit board is a professional circuit board carefully developed by Xycom for the field of industrial control and automation. In the complex systems of industrial production, the stable operation and precise control of equipment cannot be achieved without the support of high-performance circuit boards. This circuit board, with its advanced design and reliable performance, has become an important component of industrial control systems. It can efficiently process various control signals and data transmission tasks, and is widely used in industrial automation production lines, energy monitoring systems, mechanical equipment control, and other scenarios, providing solid support for the intelligent and automated operation of industrial equipment.

Specification parameters

Circuit board type: Industrial control dedicated circuit board

Working voltage: Supports multiple industrial standard voltages (such as+V, ± 12V, etc.)

Power consumption: Low power design, typical power consumption

Working temperature range: -20 ℃ -60 ℃, suitable for harsh industrial environments

Storage temperature range: -40 ℃ -85 ℃

Core functions

(1) Accurate signal processing

The Xycom 89060B circuit board is capable of accurately processing signals from various sensors and control devices. On industrial automation production lines, it can quickly and accurately analyze analog and digital signals transmitted by temperature sensors, pressure sensors, position sensors, etc., and convert these signals into instructions that can be recognized and processed by the control system. By precise processing of signals, precise control of industrial equipment can be achieved, such as accurately adjusting the motion trajectory of robotic arms and controlling the operating speed of production equipment, ensuring the accuracy and stability of the production process and improving product quality.

(2) Efficient data transmission

It has efficient data transmission capabilities and can quickly and stably exchange data with different devices through its various industrial standard interfaces. In the energy monitoring system, it can timely transmit the collected power parameters, energy consumption data, etc. to the central control system, so that the staff can grasp the energy operation status in real time. At the same time, supporting parallel data transmission between multiple devices greatly improves data transmission efficiency, reduces data transmission latency, and ensures the real-time performance and response speed of industrial systems.

(3) Stable and reliable operation

Using high-quality electronic components and optimized circuit design, it has undergone rigorous industrial testing and verification. It can still maintain stable working conditions in harsh industrial environments such as high temperature, high humidity, and strong electromagnetic interference. The circuit board has excellent anti-interference ability, which can effectively resist the influence of external electromagnetic interference on signal transmission and data processing, ensure the normal operation of industrial equipment, reduce the risk of equipment shutdown caused by circuit board failure, and improve the continuity and reliability of industrial production.

Working principle

When the Xycom 89060B circuit board is connected to an industrial control system, it first receives input signals from sensors, control buttons, and other devices. These signals are preprocessed through signal conditioning circuits on the circuit board, such as filtering, amplification, and level conversion, to remove noise and interference from the signals and adjust them to a state suitable for subsequent processing.

The preprocessed signal is transmitted to the core processing unit of the circuit board, such as a microprocessor or dedicated integrated circuit. The core processing unit analyzes and processes signals based on preset programs and algorithms, and determines the device status or operation instructions represented by the signals. For example, if a temperature sensor signal is received, the core processing unit will convert the signal into an actual temperature value and compare it with the set temperature range to determine whether a control command needs to be issued.

The processed results are transmitted to the corresponding execution devices, such as motors, valves, display screens, etc., through the output interface of the circuit board. At the same time, the circuit board can also interact with other devices or control systems through communication interfaces to achieve collaborative work of the entire industrial system. Throughout the entire working process, the circuit board ensures stable and coordinated operation of various components through internal clock circuits and power management circuits.

Key advantages

(1) High performance and efficiency

Excellent performance in data processing and signal transmission, able to quickly respond to various needs of industrial equipment, greatly improving the efficiency of industrial production. Compared to traditional circuit boards, it has faster processing speed, more stable data transmission, can effectively shorten production cycles, and improve the production efficiency of enterprises. For example, in high-speed automated production lines, a large amount of production data and control signals can be processed in real time to ensure the efficient operation of the production line.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands