ABB AO2000-LS25 Laser Analysts User Manual

ABB AO2000-LS25 Laser Analysts User Manual

Product Overview

Core positioning: ABB AO2000-LS25 is a modular laser gas analyzer that operates in conjunction with the AO2000 integrated analysis system. It is based on tunable diode laser absorption spectroscopy (TDLAS) technology to measure gas concentration and only detects free molecules in the gas, insensitive to bound molecules.

Composition structure:

Unit Name Core Component Function Function

The transmitter unit temperature stable diode laser, collimating optical lens group, and main electronic equipment emit laser to complete laser wavelength scanning and basic light intensity measurement

The receiver unit focuses on the lens, photodetector, and electronic device at the receiving end to receive the laser absorbed by the gas, converts the optical signal into an electrical signal, and transmits it to the transmitter unit

The voltage conversion module of the power supply unit (100-240V AC to 24V DC) provides stable power supply for the transmitter and receiver, and supports direct connection to 24V DC

Protection and explosion prevention:

Conventional protection: The protection level of the transmitter and receiver units is IP66, and the standard optical window withstand voltage reaches 5 bar (absolute pressure).

Explosion proof version:

Class I Division 2 version: CSA certified, suitable for Groups A, B, C, D environments, temperature code T4, operating temperature -20~+55 ℃.

ATEX Zone 2 version: ATEX certified, certification number Presafe 16 ATEX 8621X, II 3 G Ex nA nC IIC T5 (special application T4), operating temperature -20~+55 ℃.

Key technical parameters

Description of specific indicators for parameter categories

The measurement objects CO, CO ₂, H ₂ O, NO, NO ₂, SO ₂, O ₂, CH ₄, etc. support multi-component selection and can measure up to 2 components simultaneously

Measurement accuracy ± 1% full scale based on TDLAS technology and harmonic analysis to achieve high-precision measurement

Response speed<1 second can quickly track dynamic changes in gas concentration

Operating environment temperature: -20~+50 ℃; Pressure: 1-10 bar ABS suitable for complex industrial working conditions

Laser classification O ₂ measurement is Class 1M, others are Class 1 in accordance with IEC 60825-1 standard, laser is near-infrared light (700-2400nm)

Power supply specification input: 110V-380V AC; Output: 24V DC power supply unit outputs 24V DC, transmitter unit inputs 18-36V DC

Physical characteristics: Weight of 3.6kg, warranty period of 1 year. Lightweight design with clear after-sales support

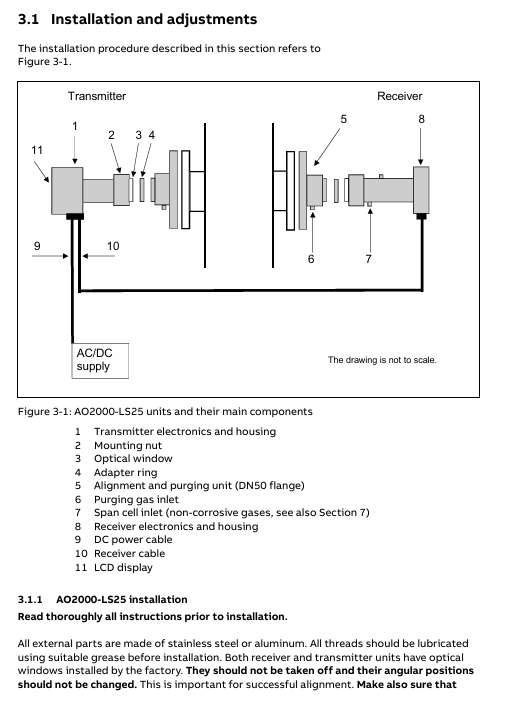

Installation and commissioning process

preliminary preparation

Tool requirements: 2 M16 open-end wrenches, 1 5mm hex wrench, 1 2.5mm flathead screwdriver, 1 PC (386 and above).

Measurement point requirements: At least 5 times the diameter of the straight pipe section is required before the measurement point, and at least 2 times the diameter of the straight pipe section is required after the measurement point; The transmitter and receiver units need to reserve operating space, and at least 1 meter of space should be reserved outside the flange of the receiver unit.

Flanges and Openings: Two pairs of perforations with a diameter of at least 50mm need to be opened on the pipeline/chimney, using DN50/PN10 standard flanges (inner diameter 50mm, outer diameter 165mm), with a flange angle tolerance of ± 1.5 °, and alignment tolerances that meet the requirements of DN50 flange δ min ≥ 40mm and DN80 flange δ min ≥ 55mm.

Cable requirements:

Special requirements for maximum length of cable type

The receiver cable is 150m long and cannot be replaced or modified at will (within ± 20m)

Ensure that all three sets of power cables are connected for a 100m power cable to ensure even current flow

Ethernet cable 100m outdoor use requires acid and UV resistance, supporting 10/100Base-T protocol

Service PC cable 10m standard length 3m, can be extended to about 10m

Installation steps

Install the alignment and blowing unit (DN50 flange) of the transmitter/receiver onto the process flange with 4 M16 × 60 bolts to ensure even compression of the O-ring.

Connect the blowing gas (instrument air or nitrogen), with a flange blowing flow rate of approximately 20-50 l/min, and a transmitter/receiver unit blowing flow rate of<0.5 l/min.

Install the window adapter ring (aligning with the positioning pin) and connect the transmitter/receiver unit to the adapter ring, paying attention to installing the O-ring (the transmitter side O-ring needs to be lubricated, while the adapter ring side O-ring is not lubricated).

Connect the cables of each unit: the receiver cable connects the transmitter and receiver, and the power cable connects the power unit and transmitter. If an external 4-20mA temperature and pressure sensor is required, it can be connected to the corresponding terminal of the power unit or transmitter.

Debugging and alignment

Startup process: After connecting the power, the instrument enters the startup mode (about 5 minutes), and the LCD displays the firmware version, self-test status, and laser temperature stability progress. If the "Laser line up error" is displayed after startup, alignment is required.

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

Email:wang@kongjiangauto.com