ABB AO2000-LS25 Laser Analysts User Manual

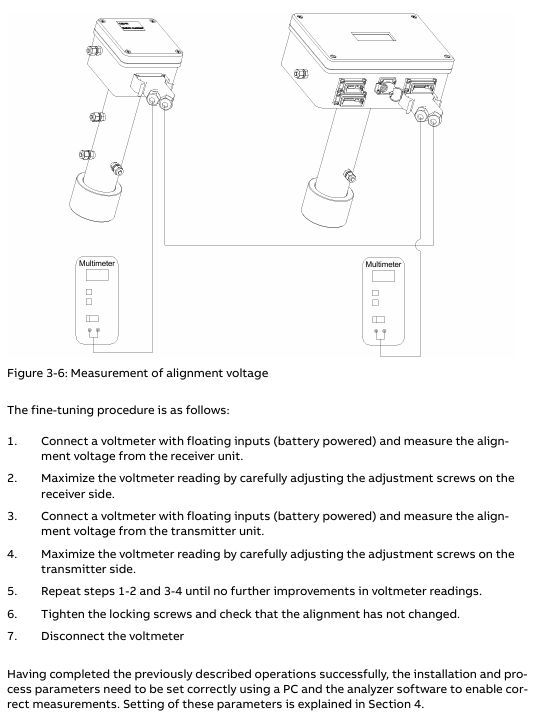

Alignment operation:

Remove the adapter ring of the transmitter/receiver and install the red laser calibration fixture.

Adjust the M16 adjustment screw on the transmitter side flange, align the laser beam with the center of the receiver side opening, and lock the locking screw.

Move the calibration fixture to the receiver side and repeat step 2 to align with the center of the opening on the transmitter side.

Connect the alignment interface of the transmitter/receiver with a voltmeter (voltage range 0V~-3V), fine tune the flange to maximize the voltage, and ensure that the transmission rate is between 90% -100% (low dust condition).

Software operation and parameter configuration

Software composition

Built in program: integrated into the CPU board, responsible for laser temperature control, signal acquisition, concentration calculation, and self checking, without the need for user operation.

Service program: Running on Windows system, connected to instruments via RS-232 or Ethernet, used for installation, configuration, calibration, troubleshooting, supporting user mode (simplified interface) and advanced mode (full functionality, password required).

Core function operation

Parameter configuration (via the "Measurement configuration" menu):

Temperature and pressure settings: Fixed value, 4-20mA input, internal sensor or spectral measurement (temperature only) can be selected, pressure unit is bar abs (gauge pressure needs to be converted: P (abs)=1.013+P (gauge)), temperature unit is ℃ (Fahrenheit conversion: T (℃)=(T (℉) -32)/1.8).

Optical Path: Set the "Optical Path Length (Gas)" (usually the diameter of the pipeline) and "Optical Path Length (Flange)" (only required when there is a target gas inside the flange). The factory preset "Optical Path Length (inside the transmitter/receiver)" cannot be modified arbitrarily.

Concentration averaging: Set the average number of times (N), and the average time Tavg=N × Tprim (Tprim is the single measurement time, 1-4 seconds, depending on the gas type).

Calibration operation (via the "Calibrate instrument" menu):

Calibration mode applicable scenario operation requirements

PROPORTIONAL's daily calibration and process gas calibration do not require temperature and pressure control, only adjusting calibration constants. It can calibrate a single gas separately and supports automatic calibration of associated gases

GLOBAL laser parameter drift, stable temperature and pressure environment (recommended 1.013bar, 23 ℃) after replacing core components, using standard gas and test cell, password authorization required

Recommended calibration gas concentrations: HF (50-500ppm, PTFE pool), HCl (15-200ppm), CO (0.5-5% vol or 50-500ppm), NO (500-5000ppm), etc.

Data log and fault viewing:

Log function: Set the sampling interval (minimum 2 seconds) through the "Log reads" menu, record parameters such as concentration, transmission rate, temperature and pressure, and support automatic generation of new files by date.

Fault viewing: The "View error log" menu displays fault/warning information (including activation/deactivation time), and can save fault logs and system logs for diagnosis. Common faults include "Low transmission" (cleaning window) and "Laser line up error" (realigning).

Maintenance and troubleshooting

routine maintenance

Regular inspection: Check the transmission rate daily, test the response with standard gas every 3 months (for at least 10 minutes), and calibrate every 3-12 months.

Window cleaning: When the transmission rate is too low, use non abrasive cleaning agents/solvents to clean the optical window. If the window has cracks, it needs to be replaced (pay attention to maintaining the original angle).

Blowing optimization: The flange blowing flow rate can be adjusted according to "blowing flow rate=1/10 process gas flow rate", and the blowing effect can be verified by observing the concentration change after turning off the blowing for 30-60 seconds.

Common faults and solutions

Analysis of the causes of fault information and solutions

Low transmission (warning) Optical window contamination, transmitter/receiver alignment deviation. Clean the optical window and re align the laser

Laser line up error: The laser beam did not reach the detector and the optical path was obstructed. Check for any obstacles in the optical path, clean the window, and realign it

PLC T-read error: Temperature sensor current exceeds the range (<0.3mA or>23.7mA). Check the sensor wiring or switch to a fixed temperature setting

Low laser temp. (Error) Laser temperature adjustment malfunction, laser supercooling check transmitter heat dissipation. If it is not overheated, it may be a hardware failure. Contact after-sales service

EEPROM error: Internal memory failure. Upload backup settings file. If it occurs repeatedly, contact after-sales service

Key issue

Question 1: What are the core differences between the two calibration modes (PROPORTIONAL and GLOBAL) of ABB AO2000-LS25 laser analyzer, and which scenarios are they applicable to?

Answer: The core differences between the two calibration modes are reflected in the calibration objects, operational requirements, and applicable scenarios:

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA