YOKOGAWA FA-M3 positioning module (with analog voltage output)

Document identification: Document number IM 34M6H58-01E, document model code DOCIM. This number must be referenced for communication and additional manual purchases; The media number is the same as the document number (CD version), and the copyright belongs to Yokogawa Electric in 1998.

YOKOGAWA FA-M3 positioning module (with analog voltage output)

Basic information and important statements

1. Applicable product and document identification

Applicable products: FA-M3 series unlimited range multi controller, specific models F3NC51-0N (single axis positioning module) and F3NC52-0N (dual axis positioning module), with the function of positioning control with analog voltage output.

Document identification: Document number IM 34M6H58-01E, document model code DOCIM. This number must be referenced for communication and additional manual purchases; The media number is the same as the document number (CD version), and the copyright belongs to Yokogawa Electric in 1998.

2. Important statement

Manual transmission: It needs to be transmitted to the end user. Before using the module, it is necessary to read the manual thoroughly to fully understand the product.

Content limitation: The manual only describes product functions and does not guarantee compatibility with specific user purposes; Without permission, partial or complete transcription or reproduction is not allowed; The content may change without prior notice.

Error feedback: Although we try our best to ensure the accuracy of the content, if any errors or omissions are found, please contact the nearest representative office or sales office of Yokogawa Electric.

Disclaimer: Yokogawa Electric only guarantees the product according to the separately provided warranty terms and is not responsible for direct/indirect losses caused by user use or unforeseeable defects of the product; The software is only for use on designated computers and is prohibited from reverse engineering, unauthorized transfer, etc.

Safety precautions

1. Definition of safety symbols

Meaning and usage scenarios of symbol types

CAUTION (product/manual) should follow the instructions in the manual to avoid personal injury, equipment damage, and other hazards such as electric shock prevention; The symbol in the manual is also used to indicate key information for understanding operations and functions

Warning (manual only): Please refer to the manual instructions to prevent hardware/software damage or system failure

TIP (manual only) provides information to supplement the current topic

SEE ALSO (manual only) indicates other sources of information to be referenced

2. Core security requirements

Grounding requirements: The functional grounding terminal (FG) must be grounded before use, and it must independently comply with Japanese Industrial Standards (JIS) Class 3 grounding, with a grounding resistance not exceeding 100 Ω, and avoid being grounded together with high-voltage power lines.

Installation environment: Avoid installation in locations with direct sunlight, temperatures exceeding 0-55 ℃, humidity exceeding 10% -90% (prone to condensation), corrosive/flammable gases, and mechanical vibrations/impacts.

Operation specification: The power must be turned off before installing/disassembling the module; Tighten the installation screws and terminal screws of the module to ensure that the interconnection cable connectors are secure and checked before powering on; An emergency stop circuit needs to be constructed using external relays to interlock with the controller status (stop/run); Avoid cleaning with solvents such as paint thinner, only wipe with a damp cloth or neutral cleaner.

Component replacement and modification: Only company designated components can be used for replacement, and it is prohibited to modify or add components to the interior of the product; The CPU module contains a built-in battery and should be stored in high temperature (storage temperature -20-75 ℃) and high humidity environments to prevent a sudden decrease in battery life.

Electrostatic protection: Before operating in a dry environment, touch the grounded metal to release static electricity.

Product specifications

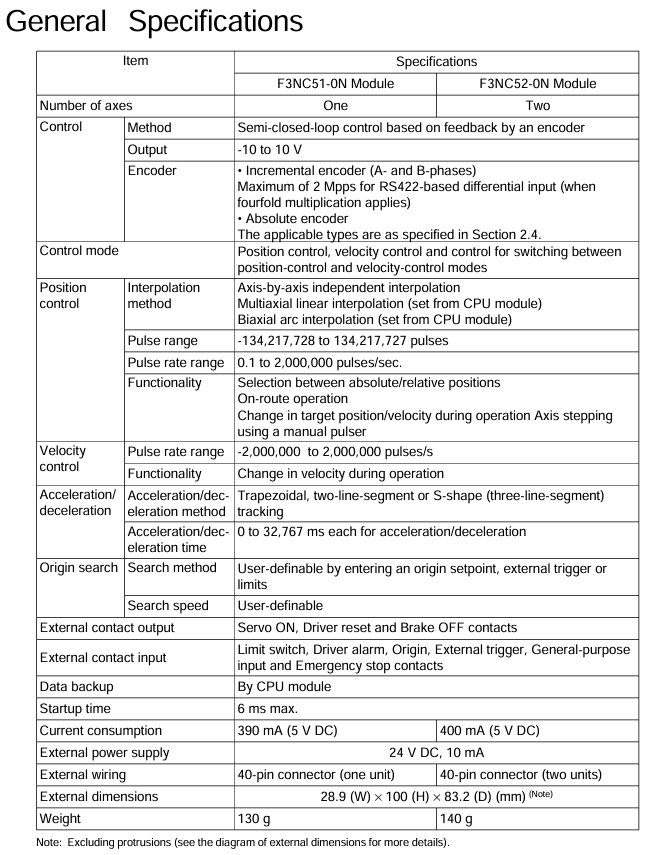

1. General specifications (core parameters)

Project F3NC51-0N (single axis) F3NC52-0N (dual axis) Description

Control the number of axes: 1 axis and 2 axes-

Control method based on encoder feedback semi closed loop control based on encoder feedback semi closed loop control-

Analog voltage output -10~10V -10~10V for speed control commands

Encoder compatibility incremental encoder (A/B phase, RS422 differential input, maximum 2Mpps at 4x); Absolute encoders (Yokogawa ∑ series, Sanyo Electric Manchester encoder series, etc., see Section 2.4 for details) are the same as single axis encoders-

Control mode position control, speed control, speed position control mode switching are the same as single axis-

Position control function axis independent interpolation, multi axis linear interpolation, dual axis arc interpolation; Pulse range -134217728~134217727 pulses; Pulse frequency ranging from 0.1 to 200000 pulses per second; Support absolute/relative position selection, operation in the path, target position/speed change during operation, manual pulse generator axis stepping with single axis-

Pulse frequency range for speed control function -2000000 to 2000000 pulses per second; Support speed changes during operation on the same single axis-

Acceleration and deceleration methods include trapezoidal, two-stage, and S-shaped (three-stage) tracking, with single axis acceleration and deceleration times ranging from 0 to 32767ms each

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA