Emerson AMS Suite: Machinery Health ™ Manager v5.61 Software Installation Guide

Emerson AMS Suite: Machinery Health ™ Manager v5.61 Software Installation Guide

Overview

This document is AMS Suite: Machinery Health ™ The installation guide for Manager v5.61 covers software installation types, operational requirements, installation steps, additional component installation, service configuration, and other content, aiming to guide users in completing the installation and related configuration work of the software.

Introduction Information

Customized installation media: According to the order, the software installation DVD includes independent (single user) or network installation versions, AMS Machinery Manager technology, and the number of licensed users. Adding technology or adding licensed users requires contacting an Emerson sales representative.

Ways to obtain assistance

After starting the software, select "Help" from the main menu.

The manual DVD in the software package contains a PDF format user manual.

Software registration can be done through phone, email, or website, and product support can also be obtained through the corresponding phone, email, and website.

Installation Type

Independent installation: allows the use of periodic technology and CSI Machinery Health analyzer on one computer, which is a single software with a single serial number on one computer. It can install AMS Machinery Manager, AMS Standalone Data Transfer (on another computer), AMS Machinery Manager ODBC Driver and other components.

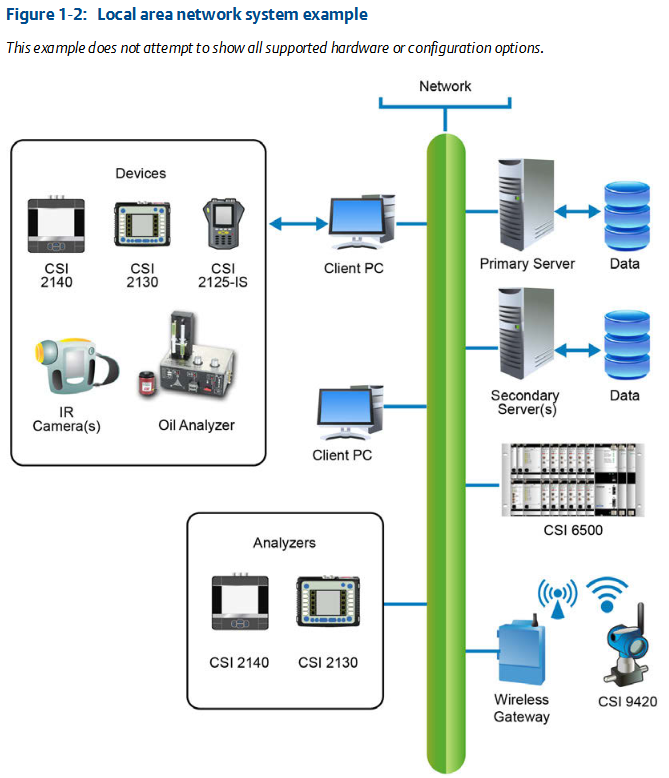

Network installation: allows the use of online and periodic technologies to communicate with CSI Machinery Health Monitor through network connections, can be deployed on local or wide area networks, and can install more components, including Online Server, Secondary Database Server, etc. Network installation is divided into single user network, multi-user network, and multi-user wide area network forms.

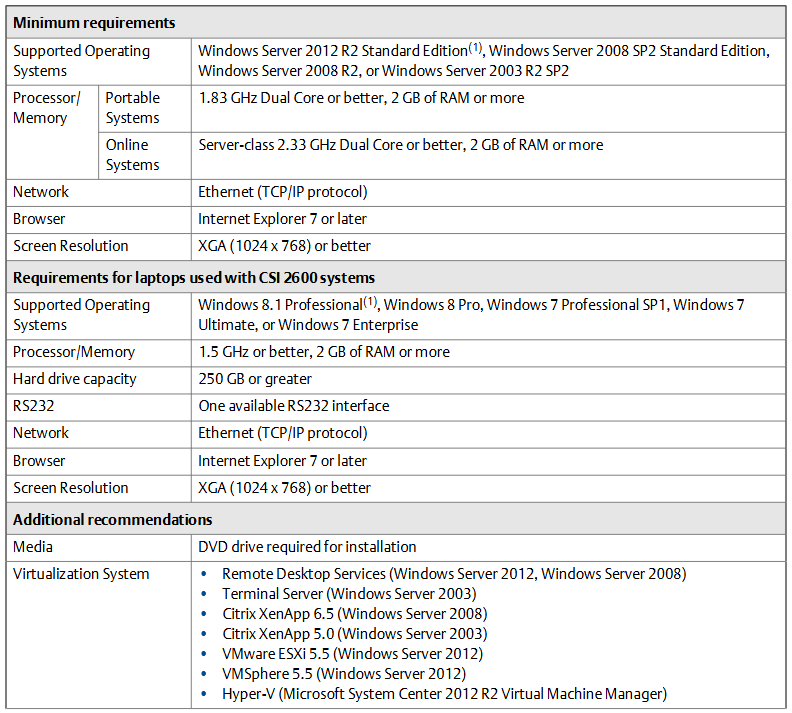

Operation requirements

Server: lists the minimum requirements for supported operating systems, processors/memory, networks, browsers, screen resolutions, as well as special requirements for laptops used with the CSI 2600 system, and recommendations for virtualization systems and antivirus software.

Workstation: including minimum requirements and additional recommendations for supported operating systems, processors/memory, networks, browsers, screen resolution, communication requirements (RS232, USB), as well as antivirus software recommendations.

Localization precautions: The software can be authorized in English or localized versions. When installing, it is important to ensure the validity of the computer name. Different versions of Windows systems have different language and regional requirements for installing localized software.

Independent installation

Installing AMS Machinery Manager: It is necessary to first confirm that the client computer meets the workstation operation requirements, and backup the database before upgrading the software. The installation steps include logging in as an administrator, running the installation program, and installing necessary components NET Framework、 Accept the license agreement, confirm installation prompts, verify system requirements, select installation features and location, start installation, handle firewall prompts, register software, and complete installation and restart (if necessary).

Start AMS Machinery Manager: Find the program from the Start menu and select it. When logging in, the default administrator user has no password, but other users can also log in. You can also set the administrator password and create a new user in Help.

Update or repair installation: Close all related programs and services, insert the installation DVD and run the installation program, select "Add/Update" or "Repair", choose the installation function, replace files in the data directory (if necessary), start the installation and complete the subsequent steps, and restart the computer if necessary.

Network installation

Network installation overview: Before installing Machine History Viewer or CSI Data Provider, Internet Information Services must be installed first, and the database must be backed up before upgrading the software. The installation steps are to first install the network server on the server, then install the client on the workstation, and then install the secondary server and client on other computers on the network. You also need to configure the service account and firewall settings, and further configure each CSI Machinery Health Monitor.

Install network server: Confirm that the computer meets the system requirements, backup the database before upgrading, create a shared folder in advance when installing to a non-C drive, and install necessary IIS components first. The installation steps include administrator login, running the installation program, accepting the license agreement, and installation NET Framework、 Confirm installation prompts, verify system requirements, select installation features and location, start installation, handle firewall prompts, register software, and complete installation and restart (if necessary). After installation, a shared folder will be created.

Installing AMS Machinery Manager client: First, install the network server and confirm that the client computer meets the requirements and the workgroup or domain settings match. The installation steps include administrator login, browsing to the shared folder of the network server, running the installation program, selecting installation features and shortcuts, starting installation and completing subsequent steps, and restarting the computer if necessary.

Launch AMS Machinery Manager client: Find the program from the Start menu and select it. Login is similar to a standalone installation.

Installing a secondary database server: You need to first install a network server and ensure that the workgroup or domain settings match. The installation steps include administrator login, browsing to the shared folder, running the installation program, following installation instructions, accepting the license agreement, confirming installation prompts, selecting installation features and location, starting installation and completing subsequent steps, and restarting the computer if necessary. After installation, you need to create and share the CustData folder, and add a database server in network management.

Installing an online server: CSI Machinery Health Monitor is usually pre configured, and when installing additional online servers, a database server must also be selected. The installation steps include administrator login, browsing to the shared folder, running the installation program, following instructions, selecting online server and database server on the installation options page, etc. After installation, it is necessary to verify that the relevant services have been started, create and share the CustData folder, and set up the online server in network management.

Install data import server and client: Only available in network systems authorized for data import functionality, can be installed together or separately on network servers or other computers. Install the required updates or new features on the existing network server and select the corresponding components; To install on a secondary server or workstation, it is necessary to confirm that the system requirements and domain settings match, run the installation program according to the steps, and select components for installation.

Installing collaboration tools: After installation on both the network server and client, users who log in using the same network server can communicate and share information with each other. When installing on a network server, the corresponding services will be installed. To install on the client, the network server and client need to be installed first. The installation steps include administrator login, browsing to the corresponding directory in the shared folder, running the installation program, and completing the subsequent steps. When starting, select from the client's main menu.

Updating or installing new features on a network server: All related programs and services need to be closed, logged in to the network server as an administrator, ran the installation program, selected "Add/Update", selected the installation feature, started the installation and completed the subsequent steps, restarted the computer if necessary, and registered when updating software.

Additional installation

Installing Machine History Viewer: Used in conjunction with AMS Suite software, it is a browser based application. Before installation, it is necessary to install Internet Information Services (IIS) with specific features. Installing multiple components on a network server can be done in compact, recommended, or distributed configurations. The installation steps include browsing to the installation directory, running the installation program, accepting the license agreement, selecting the installation components, and installing necessary ones NET Framework、 Select the SQL Server installation location, set the SQL password, configure the installation location and network server name, etc. After completion, you can start it through the recorded URL. Before starting, you need to confirm client requirements, enable browser cookies, create users, and authorize database access.

Install AMS Standalone Data Transfer: Used to transfer routing files between the analyzer and folders on the computer or network, and cannot be installed on computers with AMS Machinery Manager already installed. The installation steps include browsing to the installation directory, running the installation program, accepting the license agreement, following the installation instructions, installing the CSI USB driver, and completing the installation.

Install AMS Machinery Manager ODBC Driver: Optional installation for accessing information from third-party software. The installation steps include browsing to the installation directory on the computer where the driver is to be installed (with the client already installed), running the installation program, accepting the license agreement, selecting the installation location, starting the installation and completing the subsequent steps, and restarting the computer if necessary.

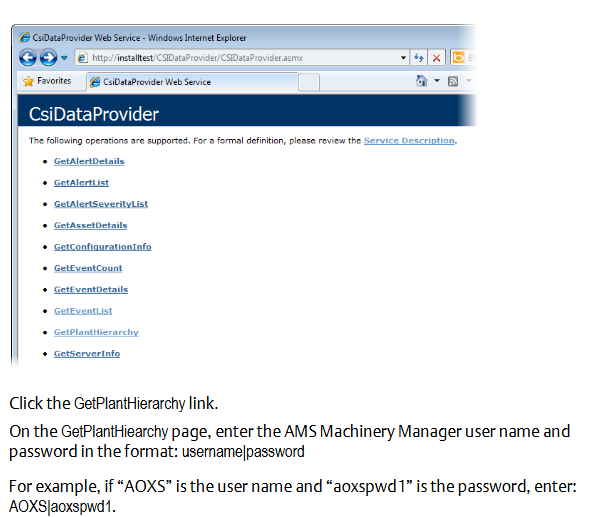

Install AMS Machinery Manager CSI Data Provider: To work with network servers to provide information for other applications, a specific version of AMS Machinery Manager support is required. Before installation, it is necessary to install IIS with specific features, which can be installed on a network server or other computer with network access permissions. The client must have been installed, the version must match, and more NET Framework 4.0。 The installation steps include browsing to the installation directory, running the installation program, accepting the license agreement, following the installation steps, confirming system requirements, setting the installation location and network server name, installing and starting relevant services, recording URLs, and completing the installation. You also need to create a user with guest access mode and authorize database access. When registering a user, access the URL through a browser and follow the steps. To create a data source, refer to the corresponding product documentation. You also need to configure the web server settings (start related services, install ASP. NET, enable ASP. NET execution, and add to a trusted site).

Install CSI USB driver: Automatically installed with AMS Machinery Manager or AMS Standalone Data Transfer, and can also be installed on any computer that requires connection to the relevant analyzer. The installation steps include browsing to the installation directory, running the installation program, accepting the license agreement, following the installation instructions, handling security prompts, and completing the installation.

AMS Machinery Manager Service

Main server functions and services: The main server is a computer that hosts a network server, listing the installed functions, corresponding services, descriptions, and purposes, such as standalone or network server corresponding to CsiNetAdmin service for authorization, etc.

Secondary server functions and services: After installing the network server, one or more functions can be installed on computers in the network. The installed functions, corresponding services, and purposes are listed, such as Database Server corresponding to CSIMTDBMgr Service for database read/write indexing, etc.

Client installation function: After the main server is installed, one or more functions can be installed, listing additional installed components, corresponding services, and purposes, such as Collaboration Tool without services, used to allow user communication, etc.

Configure network computer communication

Configure firewall settings: The AMS Machinery Manager program communicates with each other through communication ports, which may be blocked by the firewall by default. During installation, Windows may prompt to allow access and create exceptions, or manual configuration may be required. The names, numbers, types, services, executable files, connections, and purposes of the main server port, data import server port, database server port, collaboration tool server port, CSI data provider port, Machine History Viewer server port, server required port for hosting shared Cusdata folders, client and data import client required ports, online server port, OPC data port, FTP port, and optional troubleshooting ports are listed separately.

Service account: A service account is not required, but it may be useful when the service on the secondary server is difficult to establish a connection with the primary server. You can try updating the firewall settings first, and create a service account if it fails. To create a service account, you need to follow the instructions of the operating system to create a specific user account and add it to the administrator group after installing the software. Then, assign the account to each AMS Machinery Manager service, including creating the same account on the computer where the relevant service is installed. When assigning, update the login information in the service properties and restart the service. Afterwards, you can test the validity of the service account by starting the client or verifying the service function.

File Location (Appendix A)

The file location depends on the installation type. Independent systems use absolute paths, while network systems use network paths (UNC format). Listed are the types and locations of different types of files (such as installation directories, system files, data files, etc.) for independent installations, network single license or multi license servers, and network clients, as well as descriptions of each type of file.

Register AMS Machinery Manager

You can register during installation, or cancel registration later. Registration is also required when updating or repairing software. The prerequisites and steps for registering independent and network systems were explained separately, including running the registration program, contacting product support to obtain response codes, entering codes, and verifying registration status.

Update the firmware of CSI Machinery Health Monitor

Emerson regularly releases firmware updates, and it is recommended to update the firmware at the same time as updating the software (if there is a new version). The update steps include installing firmware on the FTP server (confirming prerequisites and running the installation program according to the steps), restarting the CSI Machinery Health Monitor (cycling power and verifying system status), and checking the firmware version in AMS Machinery Manager (logging into the client and checking whether the firmware version in the device properties matches through a specific path).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands