Emerson AMS Suite: Machinery Health ™ Manager v5.61 Software Installation Guide

Emerson AMS Suite: Machinery Health ™ Manager v5.61 Software Installation Guide

Overview

This document is AMS Suite: Machinery Health ™ The installation guide for Manager v5.61 covers software installation types, operational requirements, installation steps, additional component installation, service configuration, and other content, aiming to guide users in completing the installation and related configuration work of the software.

Introduction Information

Customized installation media: According to the order, the software installation DVD includes independent (single user) or network installation versions, AMS Machinery Manager technology, and the number of licensed users. Adding technology or adding licensed users requires contacting an Emerson sales representative.

Ways to obtain assistance

After starting the software, select "Help" from the main menu.

The manual DVD in the software package contains a PDF format user manual.

Software registration can be done through phone, email, or website, and product support can also be obtained through the corresponding phone, email, and website.

Installation Type

Independent installation: allows the use of periodic technology and CSI Machinery Health analyzer on one computer, which is a single software with a single serial number on one computer. It can install AMS Machinery Manager, AMS Standalone Data Transfer (on another computer), AMS Machinery Manager ODBC Driver and other components.

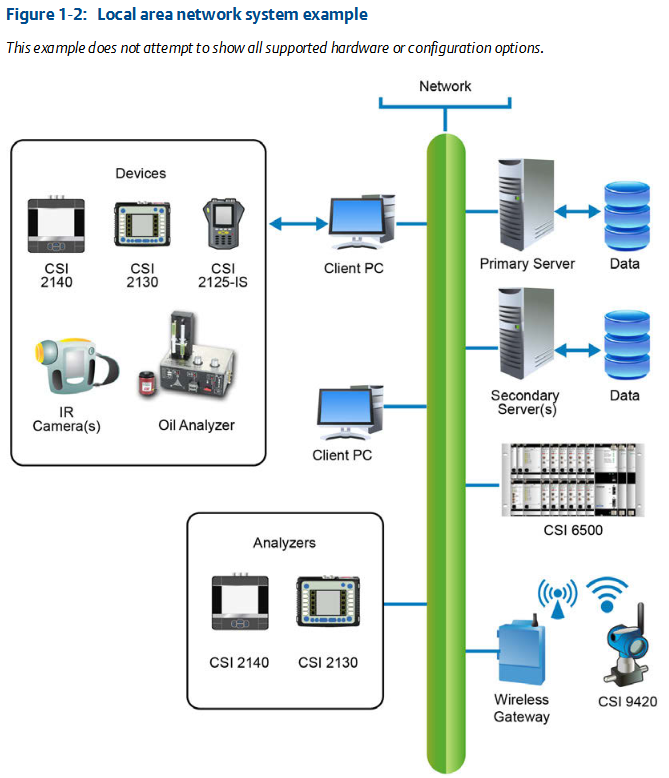

Network installation: allows the use of online and periodic technologies to communicate with CSI Machinery Health Monitor through network connections, can be deployed on local or wide area networks, and can install more components, including Online Server, Secondary Database Server, etc. Network installation is divided into single user network, multi-user network, and multi-user wide area network forms.

Operation requirements

Server: lists the minimum requirements for supported operating systems, processors/memory, networks, browsers, screen resolutions, as well as special requirements for laptops used with the CSI 2600 system, and recommendations for virtualization systems and antivirus software.

Workstation: including minimum requirements and additional recommendations for supported operating systems, processors/memory, networks, browsers, screen resolution, communication requirements (RS232, USB), as well as antivirus software recommendations.

Localization precautions: The software can be authorized in English or localized versions. When installing, it is important to ensure the validity of the computer name. Different versions of Windows systems have different language and regional requirements for installing localized software.

Independent installation

Installing AMS Machinery Manager: It is necessary to first confirm that the client computer meets the workstation operation requirements, and backup the database before upgrading the software. The installation steps include logging in as an administrator, running the installation program, and installing necessary components NET Framework、 Accept the license agreement, confirm installation prompts, verify system requirements, select installation features and location, start installation, handle firewall prompts, register software, and complete installation and restart (if necessary).

Start AMS Machinery Manager: Find the program from the Start menu and select it. When logging in, the default administrator user has no password, but other users can also log in. You can also set the administrator password and create a new user in Help.

Update or repair installation: Close all related programs and services, insert the installation DVD and run the installation program, select "Add/Update" or "Repair", choose the installation function, replace files in the data directory (if necessary), start the installation and complete the subsequent steps, and restart the computer if necessary.

Network installation

Network installation overview: Before installing Machine History Viewer or CSI Data Provider, Internet Information Services must be installed first, and the database must be backed up before upgrading the software. The installation steps are to first install the network server on the server, then install the client on the workstation, and then install the secondary server and client on other computers on the network. You also need to configure the service account and firewall settings, and further configure each CSI Machinery Health Monitor.

Install network server: Confirm that the computer meets the system requirements, backup the database before upgrading, create a shared folder in advance when installing to a non-C drive, and install necessary IIS components first. The installation steps include administrator login, running the installation program, accepting the license agreement, and installation NET Framework、 Confirm installation prompts, verify system requirements, select installation features and location, start installation, handle firewall prompts, register software, and complete installation and restart (if necessary). After installation, a shared folder will be created.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands