GE AT868 AquaTrans ™ Ultrasonic water flowmeter

GE AT868 AquaTrans ™ Ultrasonic water flowmeter

Product Overview

Core functions

AT868 is an ultrasonic water flow meter (supporting 1 or 2 channels) that measures water flow velocity, volumetric flow rate, and mass flow rate based on the principle of time difference. It is suitable for flow monitoring of single-phase fluids such as clean water and sewage. It emits and receives signals through ultrasonic sensors, calculates fluid flow velocity, and converts it into flow data, supporting real-time display, data recording, and multiple output methods (analog, pulse/frequency).

Main features

Multi channel configuration: Standard 1 channel, optional 2 channels, improve accuracy by measuring average, difference, or sum through dual channels.

Flexible sensor types: Supports wet and clamp on sensors to meet different pipeline installation requirements.

Rich output and communication: equipped with 0/4-20mA analog output, pulse/frequency output (for total count), supports RS232/RS485 serial communication, compatible with PanaView ™ Software remote operation.

High adaptability: Suitable for pipe diameters ranging from 0.04 inches to 200 inches (1mm to 5m), with flow rates ranging from -40 to 40 feet per second (-12.2 to 12.2m/s), meeting the needs of industrial pipeline flow monitoring.

Installation and wiring

1. Installation points

Sensor location: It needs to be installed in a straight pipe section, with at least 10 times the upstream pipe diameter and at least 5 times the downstream pipe diameter without turbulence interference (such as valves, elbows); Prioritize installation on the side of the pipeline (to avoid gas accumulation at the top or slag accumulation at the bottom).

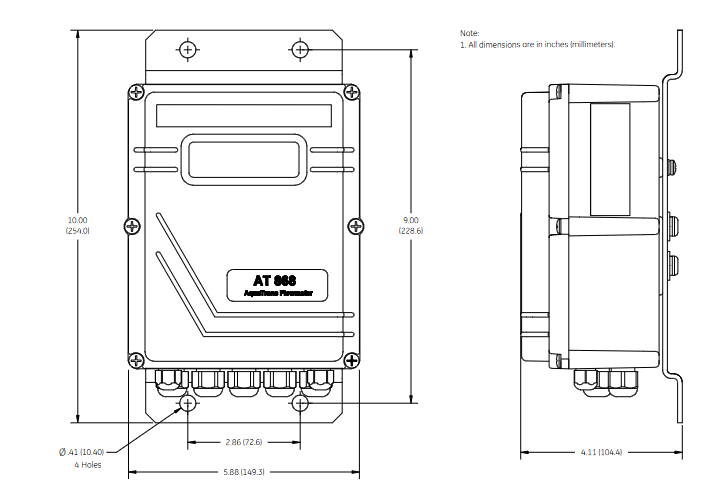

Electronic enclosure: Adopting NEMA 4X/IP66 protection level, suitable for indoor and outdoor installation, should be close to the sensor to shorten the cable length (supporting up to 1000 feet/300 meters).

Pipeline requirements: It is necessary to measure the outer diameter, wall thickness, material and other parameters of the pipeline and program them to ensure the accuracy of flow calculation.

2. Wiring specifications

Power supply: Supports 85-265VAC or 12-28VDC, requires an external power-off device (such as a switch) that complies with the EU Low Voltage Directive, installed within a range of 6 feet.

Sensor wiring: Plug in or clip on sensors are connected through coaxial cables, and the cable length needs to be matched (with an error of ≤ 4 inches for frequencies ≤ 2MHz and ≤ 0.5 inches for frequencies>2MHz).

Output wiring:

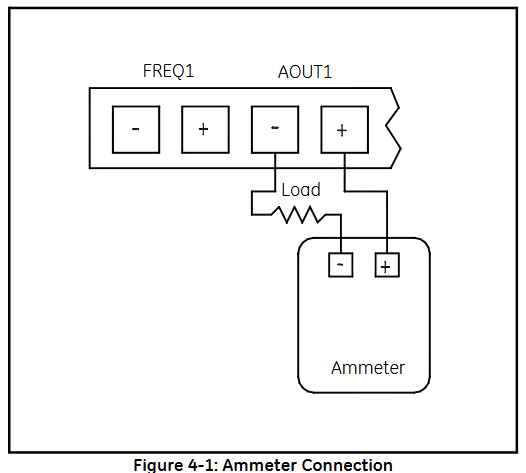

Analog output (0/4-20mA): Load resistance ≤ 600 Ω, used for transmitting flow signals.

Pulse/frequency output: used for total count or frequency proportional to flow, maximum load 3A@100VDC .

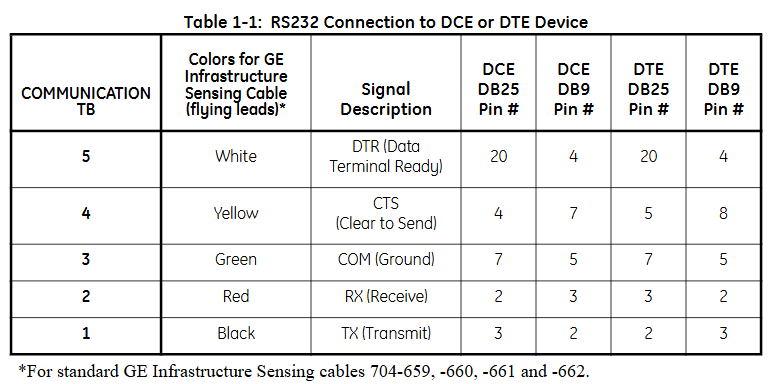

Communication wiring: RS232 is used to connect to PCs or printers, RS485 supports multi device networking, and must follow shielding grounding specifications to resist interference.

Programming and Settings

1. Basic parameter configuration

Channel activation: Activate the channel through the CHx ACTIV menu and select the sensor type (standard or special).

System parameters: Set the flow unit (such as gallon/minute, cubic meter/hour), total unit, and decimal places in CHx SYSTM, and optional mass flow rate (fluid density needs to be entered).

Pipeline and sensor parameters: Enter pipeline material, outer diameter, wall thickness, sensor frequency, path length (P), and axial length (L) in CHx PIPE. For clamp on sensors, lining parameters (material, thickness) also need to be set.

2. Advanced feature settings

Response time: Set the average measurement response time through the AVRG menu. It is recommended to select the "STATS" mode (fast response in steady state, fast tracking when flow changes).

Zero flow cutoff: Set a zero flow threshold (0-1 feet/second) in CHx I/O to avoid reading deviations caused by small fluctuations.

Tracking window: When the fluid sound velocity is unknown or fluctuates greatly, enable Tracing WINDOW to automatically track the sound velocity to ensure measurement accuracy.

Display function

1. Display screen and indicator lights

LCD display screen: A 2-line x 16 character LCD display screen that supports backlight adjustment and can display real-time measurement data, set parameters, and error codes.

Display content: It can be configured to display up to 4 parameters, including:

Flow rate (feet/second, meters/second)

Volume flow rate (such as gallons per minute, cubic meters per hour)

Accumulated total amount (such as total cubic feet, total cubic meters)

Diagnostic parameters (such as signal strength, sound speed, time difference, etc.)

Wheel display function: If multiple parameters are configured, the display screen will cycle at set intervals, with each parameter staying for a few seconds.

2. Display settings

Enter the settings menu:

Press [ESC]+[ENTER]+[ESC] to enter the user program.

Navigate to PROG → GLOBL → I/O → LCD, set the number of display parameters and specific parameters.

Parameter selection: Select the content to be displayed from the measured values (flow rate, flow rate) and diagnostic values (signal strength, sound velocity), supporting custom units (imperial/metric).

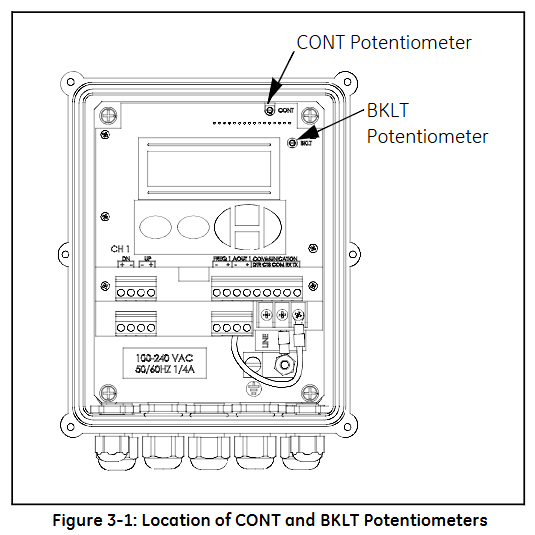

Contrast and brightness adjustment: Manually adjust through the potentiometer (CONT contrast, BKLT backlight) behind the panel to ensure clear visibility in different lighting environments.

Operation function

1. Totalizer Reset

Used to reset the accumulated traffic value to zero, supporting three methods:

Panel operation:

Enter the RESET menu and select YES to confirm the reset.

After resetting, the total amount of all channels will be reset to zero and accumulation will resume.

External switch reset:

Wiring should be done in advance (refer to the installation section) and configured as RESET in GLOBL-SYSTM → GATE OPTION.

Press and hold the external switch for 1 second, and the total amount will automatically reset to zero.

Software reset: via PanaView ™ The Clear Instrument Totalizers function of the software can be remotely operated.

2. Measurement pause and restart

Only supported through PanaView ™ Software operation:

Pause: Select Stop Measurement in Edit Functions → PAUSE MEASURMENT to pause the flow meter measurement and maintain the output signal at its final value.

Restart: Select Measure Flow to restore the measurement and update the output signal synchronously.

3. Diagnosis and Error Viewing

Diagnostic parameter display: Configure and display diagnostic parameters in GLOBL → I/O → LCD, including:

Upstream and downstream signal strength (SS up/SS dn, normal range 50-75)

Speed of Sound (SNDSP)

Time difference (DELTA T, normal ≤ 1 μ s)

Signal quality (Qup/Qdown, normal ≥ 1200)

Error code: The display screen directly shows error codes (such as E1 indicating weak signal, E3 indicating flow rate exceeding limit). You can refer to Chapter 5 of the manual to investigate the cause (such as sensor alignment deviation, bubbles in the pipeline, etc.).

Key operation and menu navigation

1. Button functions

ESC: Exit the current menu or cancel the operation.

ENTER: Confirm the selection or enter the submenu.

↑/↓: Up and down navigation menu options or adjust parameter values.

←/→: Move the cursor (used to locate the digit when modifying parameters).

2. Common menu paths

View real-time data: default display interface, press ENTER to cycle through preset parameters.

Enter programming mode: ESC → ENTER → ESC → PROG, configurable channel parameters, units, outputs, etc.

Calibration output: ESC → ENTER → ESC → CALIB, used for calibrating 4-20mA analog output or pulse frequency output.

4、 Precautions

Display refresh rate: By default, it updates with the measurement cycle (response time can be set through the AVRG menu, ranging from 0.1-99 seconds).

Total overflow: When the cumulative value exceeds the maximum range, E9: Totalizer Overflow is displayed, and the total amount needs to be reset or the unit needs to be expanded (such as changing from "gallon" to "million gallon").

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands