How to determine if the GE MLJ synchronous check relay is in calibration mode?

How to determine if the GE MLJ synchronous check relay is in calibration mode?

Product Overview

Core functions

MLJ is a digital synchronous inspection relay mainly used to detect the synchronization conditions of two electrical systems (such as the generator and the power grid, and the two sections of the power grid). By measuring the voltage difference (Δ V), frequency slip (Δ f), and phase angle difference (Δθ) between the bus voltage (VB) and the line voltage (VL), it determines whether the circuit breaker closing conditions are met and outputs a closing permission signal.

Typical application scenarios

Generator and system grid connection

Reconnect the two regions of the system

Manual closing or automatic reclosing of circuit breakers

Verify synchronization conditions to avoid equipment damage caused by asynchronous closing

Core functions and working principles

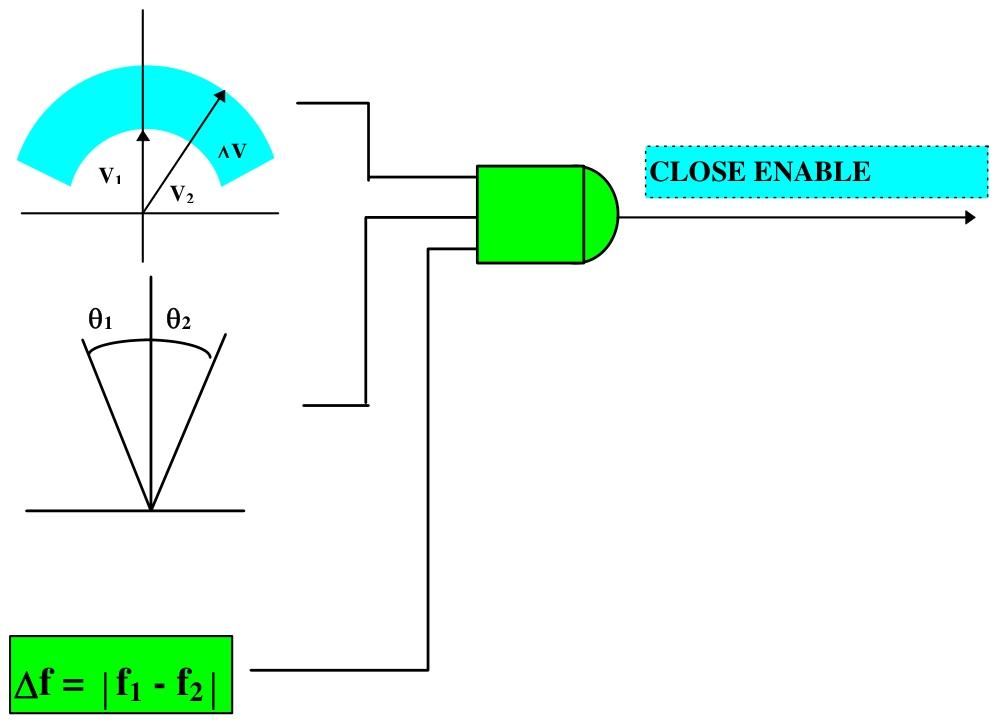

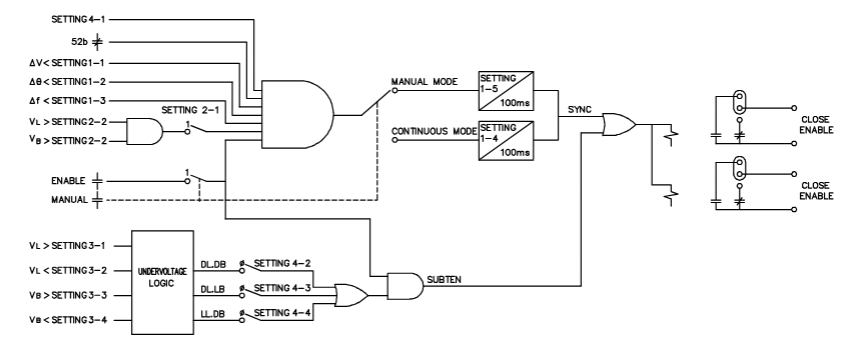

1. Synchronous inspection unit

Measurement parameters:

Voltage difference (Δ V): The absolute difference in voltage between the bus and the line, ranging from 2-90V (default 15V).

Phase angle difference (Δ θ): The phase difference between two voltages, ranging from 2-60 ° (default 10 °).

Frequency slip (Δ f): The frequency difference between two voltages, ranging from 10-500MHz (default 20mHz).

Working mode:

Continuous mode: Continuous monitoring of synchronization conditions, with a delay of 0.1-99.0s (default of 0.1s) before allowing the output to close.

Manual mode: Monitoring is triggered by external signals, and after a delay of 0.1-99.0s (default 10.0s), the output allows for closing.

Allowable conditions for closing: Δ V, Δ θ, and Δ f are all less than the set values and continuously meet the set delay.

2. Undervoltage unit

Independently monitor the voltage status (live/dead) of lines and busbars, supporting three combination modes:

DLDB (Loss of Line - Loss of Power Bus)

DLLB (Lost Line - Live Bus)

LLDB (Live Line - Dead Bus)

Voltage thresholds can be set: line/bus live threshold (VL ↑/VB ↑, 40-245V), and power-off threshold (VL ↓/VB ↓, 10-180V).

3. Input/output unit

Digital input: 3-channel DC input, including circuit breaker status (allowing synchronous check when open), manual mode trigger, and enable signal.

Output contacts: 5-way relay contacts, including 2-channel closing permission (default normally open), 1-channel alarm (default normally closed), and 2-channel configurable auxiliary contacts (supporting signal outputs such as synchronization, undervoltage, and power loss).

4. Self check and Communication

Continuously monitor memory (ROM/RAM/EEPROM), analog circuits, etc., output alarms and display error codes when faults occur (e.g. 8.0 indicates ROM failure).

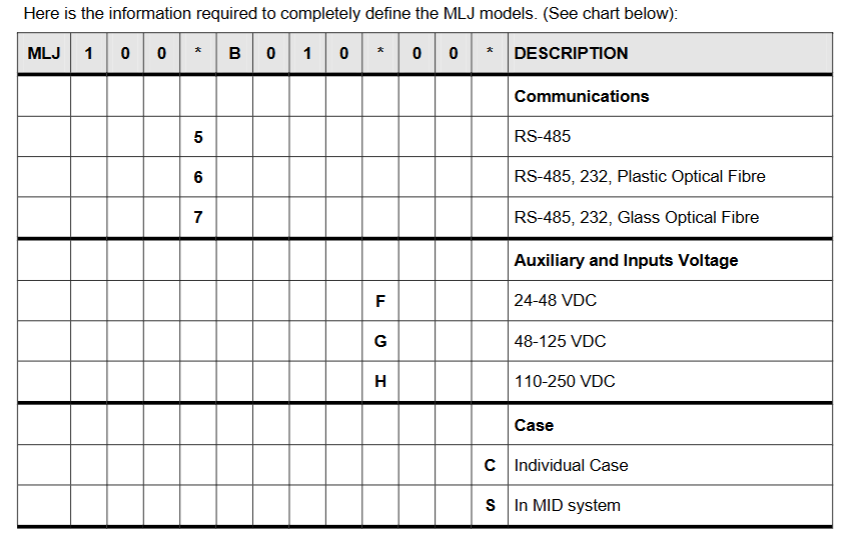

Supports RS-485 communication (optional fiber optic interface), baud rate 0.3-38.4kbaud (default 9.6kbaud), and supports Modbus protocol.

Technical specifications

Electrical parameters

Rated voltage: 63-220Vac (continuous withstand 440Vac).

Auxiliary power supply: 24-48Vdc, 48-125VDC, 110-250Vdc (± 20% fluctuation).

Measurement accuracy: Voltage ± 2% or 0.5V; Angle ± 1 ° (at 20-220Vac); Frequency slip ± 5mHz.

Contact capacity: Closing allows contact 4000VA (maximum 440Vac/300Vdc), auxiliary contact 1760VA.

Environmental and Physical Characteristics

Working temperature: -25 ° C to+55 ° C, storage temperature: -40 ° C to+70 ° C.

Humidity: ≤ 95% (no condensation).

Shell: Made of steel plate material, supporting panel installation or MID system integration, weighing approximately 3kg.

Operation interface and navigation

1. Front end devices

Button: Three vertically arranged buttons, from top to bottom, are ENTER (confirm/enter),+(add/next), and - (decrease/previous).

Display: A 3-digit 7-segment LED display screen used to show parameter values, status codes, and settings.

Indicator lights: 3 LED indicator lights, namely:

READY (green): The relay is ready and the protection function is enabled.

52 (red): The conditions for closing are met.

27 (red): The undervoltage condition is met.

2. Switching between working modes

Reading mode: default power on mode, displaying real-time data and status. Press ENTER to cycle through the various functional items (F0-F12).

Setting mode: In read mode, press ENTER and - simultaneously to enter and modify parameters. After setting up, press+and - simultaneously to return to read mode; If there is no operation for 2 minutes, it will automatically return.

Calibration mode: In reading mode, press ENTER and+simultaneously to enter and display the average values of line voltage and bus voltage for calibration.

Read mode function (F0-F12)

The main functions of cycling through the ENTER key include:

Functional code description

The F0 relay status displays a two digit error code (such as 0.0 indicating normal, 8.0 indicating ROM fault), with the decimal point constantly lit to distinguish the status from the numerical value.

Real time display of RMS voltage value in V for F1-F2 line voltage (VL)/bus voltage (VB).

F3 voltage difference (Δ V) displays the absolute difference between VL and VB, measured in V.

F4 phase angle difference (Δ θ) displays the phase difference between two voltages (0-180 °), and overflow (three horizontal lines) is displayed when the voltage is less than 9V.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands