ABB Advant Controller 410 Process Controller

Comprehensive functionality: supports various functions such as logic control, arithmetic operation, data processing, sequence control, PID regulation, etc., to meet the needs of complex industrial scenarios.

ABB Advant Controller 410 Process Controller

Product positioning and core advantages

Advant Controller 410 is a medium-sized process controller suitable for binary, regulating, and monitoring control. Its main advantages include:

Comprehensive functionality: supports various functions such as logic control, arithmetic operation, data processing, sequence control, PID regulation, etc., to meet the needs of complex industrial scenarios.

Flexibility and Scalability: Both hardware and software can be flexibly expanded, supporting online configuration and adding modules without interrupting operation.

Strong compatibility: Supports multiple communication protocols (such as MasterBus 300/300E, Advant Fieldbus 100, PROFIBUS-DP, etc.), and can be integrated with I/O systems such as S100 and S800.

High reliability: Supports redundant configurations such as power and communication, with RAM memory backed up by batteries (at least 4 hours) to ensure data security.

Core functions and technical features

1. Control and processing capabilities

CPU and Memory: Based on Motorola 68020 microprocessor (25 MHz), equipped with 4 or 8 MB dynamic RAM with error correction, supporting system program and application program storage.

Programming and Execution: Using ABB Master Programming Language (AMPL), supporting functional block (PC element) programming, program cycle time can be configured (usually 10 ms -2 s, extended 5 ms -32 s).

I/O capacity: Supports up to 4300 I/O points, including analog input (AI), analog output (AO), digital input (DI), and digital output (DO), supporting S100 (local I/O) and S800 (distributed I/O) systems.

2. Communication and Integration

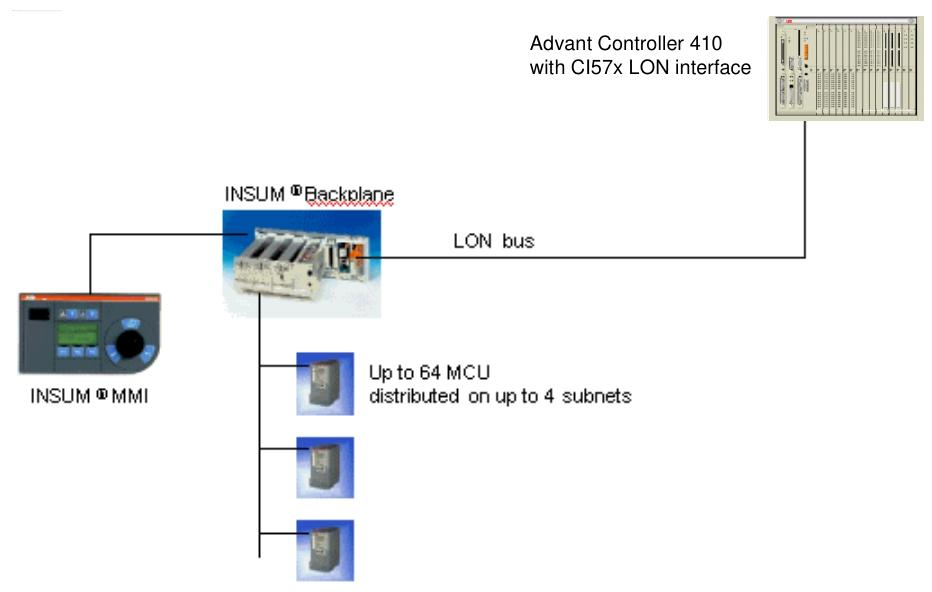

Communication interface: Supports various buses such as MasterBus 300/300E, Advant Fieldbus 100, PROFIBUS-DP, LONWorks, etc., and can connect operator stations, printers, external devices, etc.

Data exchange: Data transmission is achieved through data sets, supporting cyclic and on-demand transmission, and remote communication (such as RCOM/RCOM+, MODBUS).

3. Diagnosis and maintenance

Self diagnosis: equipped with hardware fault detection, communication error monitoring and other functions, displaying system status (such as running, error, timeout, etc.) through LED indicator lights.

Time synchronization: Supports internal clock and external synchronization (accuracy<3 ms), with event time marking accuracy up to 1 ms.

Hardware components

1. Core module

Processor module (PM150V): includes CPU, RAM, program card interface (PCMCIA), submodule slots (supporting communication interfaces, etc.), front panel with status indicator lights and operation switches (start/stop mode).

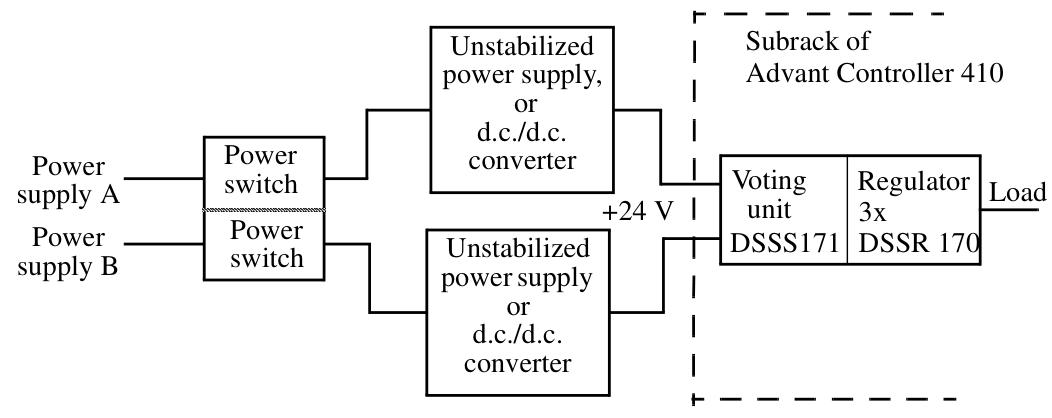

Power system: Supports 120/230 VAC or 24/48 VDC input, can be configured with redundant power supply (dual power supply+3 voltage regulators) to ensure stable power supply.

I/O system:

S100 I/O: Up to 15 I/O boards, supporting analog, digital, pulse counting, and other signals, placed on the same shelf as the CPU.

S800 I/O: Distributed I/O connected via Advant Fieldbus 100, supporting up to 79 stations per bus and up to 24 modules per station.

2. Expansion and redundancy

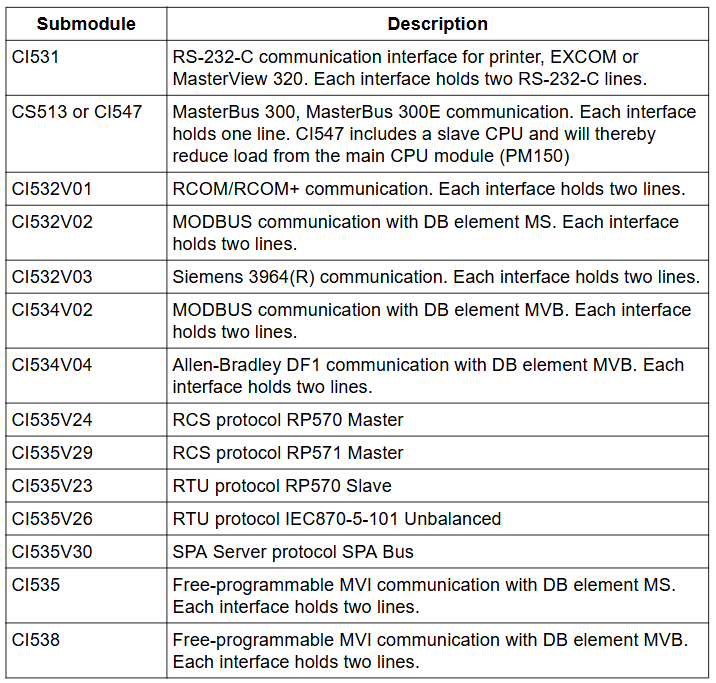

Submodule: supports communication interfaces (such as CI531 for RS-232-C, CI541V1 for PROFIBUS-DP), power regulators, etc., and is hot swappable.

Redundant configuration: Power supply, communication bus, CPU, etc. can be redundant to improve system availability.

Software components

Basic and optional modules

Basic module (QC01-BAS11): includes core PC elements such as logic, arithmetic, and data processing, supporting I/O systems and basic communication.

Optional modules:

QC01-LIB11: Extended process control functions (such as PID regulation, filters).

QC01-LIB12: Advanced process control (such as adaptive regulation, ratio control).

QC01-OPF11: Supports operator station functions such as trend display and alarm management.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands