ABB Arc Welding Robot Automation Solution

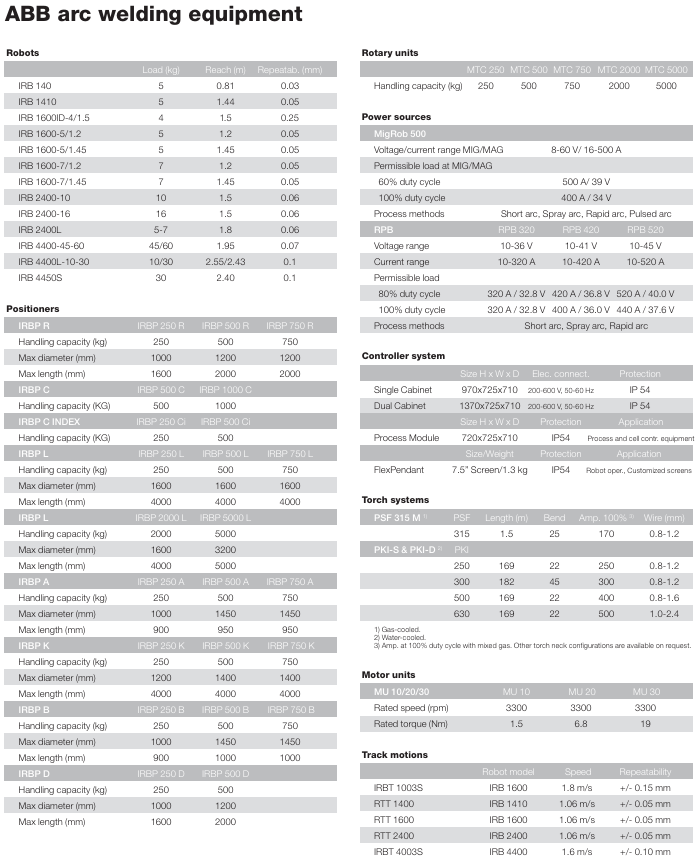

The welding gun system PKI 500 D water-cooled dual interchangeable welding gun can quickly replace Dresspack (without disassembling the welding gun), adapt to welding wire diameters of 0.8-1.6mm, and has a current of 400A at 100% load duration.

The IRC5 modular control system includes one control module and two drive modules, supports MultiMove function, and enables two robots to work independently or collaboratively.

The TSC welding gun service center automatically cleans and lubricates the welding gun, cuts the welding wire, and automatically calibrates after collision to ensure uninterrupted welding.

Workflow:

When the operator is loading and unloading workpieces at workstation A, the robot is welding at workstation B; After workstation B is completed, the positioner rotates to switch workstations, achieving seamless connection.

2. Single robot track configuration (flexible adaptation to long workpieces)

Core objective: Expand the robot's operating range through orbit, suitable for welding small and medium-sized batches of diverse long workpieces, and reduce equipment investment.

Component model/specification and function description

The IRB 1600+RTT 1600 orbital robot is installed on the track, with a track speed of 1.06m/s and a repeat positioning accuracy of ± 0.05mm. It can cover workpieces up to 6 meters long.

The RPB 520 power supply has a current of 10-520A and supports processes such as short arc and spray arc. It can output 520A at 80% load duration and is suitable for high-strength welding requirements.

The IRBP 500 L displacement machine has a load of 500kg and a maximum workpiece length of 4000mm. It rotates the workpiece horizontally to match the welding angle of the robot.

The software ArcWeld PowerPac uses the RobotStudio plugin to quickly generate welding programs, simplify parameter settings using preset templates, and shorten programming time.

Advantages: The combination of single robot and track reduces costs, and the coordinated control of track motion and robot ensures consistent welding of long workpieces.

3. Compact single workstation configuration (for small and medium batch production)

Core objective: Small footprint, suitable for scenarios with limited workshop space, balancing flexibility and economy.

Component model/specification and function description

Robot IRB 1410 has a load of 5kg and a working radius of 1.44m, suitable for small and medium-sized workpieces, with a repeat positioning accuracy of ± 0.05mm.

The MigRob 500 power supply features an integrated design that saves space and supports pulse arc welding to ensure the quality of thin-walled welding.

The displacement machine IRBP 250 R has a load of 250kg, a maximum workpiece diameter of 1000mm, and achieves multi angle welding through axial rotation.

Interface unit FlexPendant 7.5-inch touch screen+joystick, single point control of robot and power supply, simplifying operation.

Typical Configuration Example

Applicable scenarios: Small and medium-sized welding of tools, agricultural machinery, etc., optimized production rhythm and reduced downtime through WebWare monitoring system.

Common characteristics of configuration

Software and hardware collaboration: All components (such as robots, power supplies, and positioners) have been tested by ABB laboratory to ensure compatibility and reduce integration difficulty.

Flexibility: Supports offline programming (RobotStudio) and parameter optimization (VirtualArc), quickly adapting to different workpiece switching.

Reliability: The protection level of the core components reaches IP54, adapting to workshop dust and splash environments and reducing maintenance requirements.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands