ABB Arc Welding Robot Automation Solution

ABB Arc Welding Robot Automation Solution

Core advantages and applicable scenarios

Efficiency and economy: Robot automation can improve welding efficiency, reduce waste, and improve quality. The investment payback period for single or dual robot units can be as short as 6 months, which is not only suitable for long series production in the automotive industry, but also meets the short series or even single piece production needs of small and medium-sized enterprises.

Usability: Simplify programming and operation through specialized software tools, allowing operators to quickly program and reprogram, reducing implementation time.

One stop solution: Provide a complete arc welding package, including equipment and software, to simplify the procurement process, reduce costs, shorten delivery time, and all components are tested in the laboratory to ensure collaborative work.

Main components and functions

1. Robots

Core models: including IRB 140, IRB 1410, IRB 1600 series, IRB 2400 series, IRB 4400 series, IRB 4450S, etc., with a load range of 5-60kg, a working radius of 0.81-2.55m, and a repeat positioning accuracy of 0.03-0.1mm, suitable for different welding scenarios.

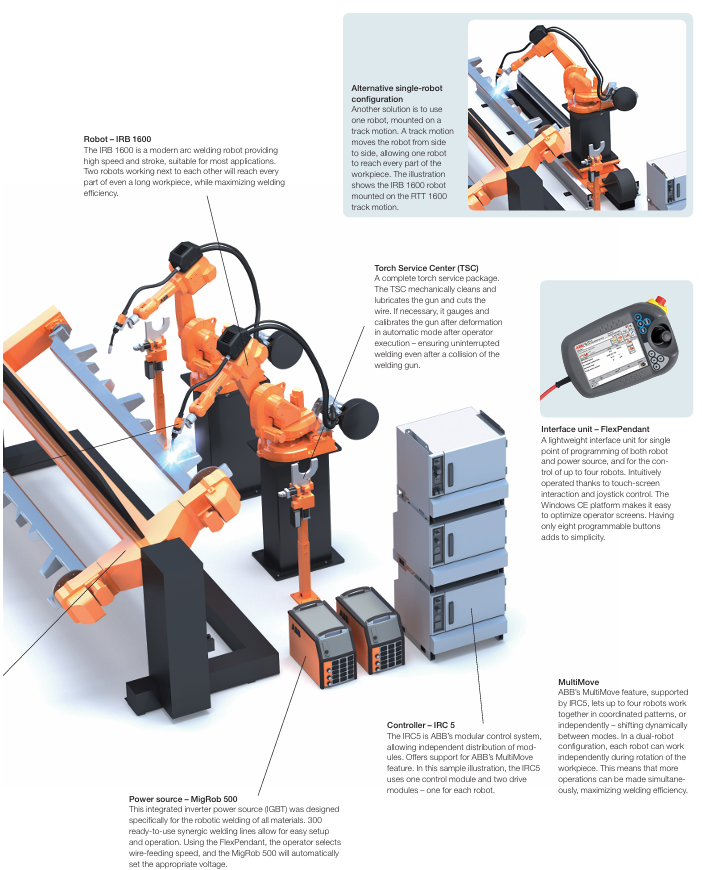

Typical applications: IRB 1600 is fast and has a large stroke, suitable for most applications. Its dual robot configuration can cover long workpieces, and when combined with orbital motion (such as RTT 1600), it can expand the operating range.

2. Power sources

MigRob 500: an integrated inverter power supply designed specifically for robot welding, supporting MIG/MAG welding, with a voltage range of 8-60V and a current of 16-500A. It includes 300 ready-made collaborative welding circuits, and the operator can automatically match the voltage after selecting the wire feeding speed.

RPB series: including RPB 320/420/520, current range 10-520A, supports short arc, spray arc, fast arc and other processes, suitable for different load requirements.

3. Positioners

Classification and Parameters: Divided by model into IRBP R/C/L/A/K/B/D series, with a load capacity of 250-5000kg, a maximum diameter of 1000-3200mm, and a maximum length of 900-5000mm, it is used to fix and rotate workpieces, making it convenient for robots to weld in all directions. For example, IRBP K 750 has a load of 750kg, can rotate axially and rotate itself, making it easy to load and unload workpieces.

4. Controller System&Interface

IRC5 controller: Modular control system, supports MultiMove function, can control up to 4 robots to work together or independently, including control module and drive module, with a protection level of IP54.

FlexPendant: Lightweight interface unit, 7.5-inch screen, supports touch operation and joystick control, programmable with 8 buttons for single point programming of robots and power supply, controlling up to 4 robots.

5. Welding gun system and auxiliary equipment

Welding gun system: including gas cooled PSF 315 M and water-cooled PKI-S/PKI-D series, with a current range of 170-500A, suitable for welding wire diameters of 0.8-2.4mm, PKI 500 D can replace Dresspack without disassembling the welding gun, saving time.

Welding Gun Service Center (TSC): Automatic cleaning and lubrication of welding guns, cutting of welding wires, automatic calibration after collision, ensuring uninterrupted welding.

Track motions: such as IRBT 1003S and RTT series, adapted to different robots, with a speed of 0.8-1.8m/s and a repeat positioning accuracy of ± 0.05-0.15mm, expanding the robot's operating range.

6. Software products

RobotStudio: a simulation and offline programming software that allows for robot programming to be completed in the office without affecting production, making it convenient for MultiMove programming.

ArcWeld PowerPac (AWPP): A plugin for RobotStudio designed specifically for generating arc welding programs, including ready-made welding templates for easy editing by users.

WebWare: a monitoring system that analyzes production trends, identifies fault causes, backs up robot systems, and accesses them through a web interface.

VirtualArc: Offline prediction and adjustment of welding parameters, simulating arcs to predict welding quality, contour, and defects, optimizing productivity and quality.

Typical Configuration Example

1. Dual station long workpiece welding unit (efficient mass production configuration)

Core objective: To achieve parallel loading, unloading, and welding of workpieces through a dual station design, maximizing robot utilization and suitable for welding workpieces up to 4 meters in length.

Component model/specification and function description

Robot IRB 1600 2 robots work together, with a load of 5-7kg, a working radius of 1.2-1.45m, a repeat positioning accuracy of ± 0.05mm, and high-speed welding to ensure efficiency.

The IRBP K 750 displacement machine has a load of 750kg and supports axial rotation of the workpiece (facilitating full angle welding of the robot) and self rotation (achieving dual station switching). The maximum workpiece length is 4000mm and the diameter is 1400mm.

The MigRob 500 power supply integrates IGBT inverter, supports MIG/MAG welding, with a current of 16-500A and 300 collaborative welding parameters, automatically matching wire feeding speed and voltage.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands