Foxboro ™ DCS Field Device Controller 280(FDC280)

In self hosted mode, the control database checkpoint file is stored in flash memory, and the host can autonomously start and execute control policies when offline

Software updates distinguish between "Major updates (new features, no online upgrade support)" and "Minor updates (only module switching, no process interruption)"

Environmental adaptability die-casting aluminum shell, no need for ventilation, supports Class G3 harsh environment (ISA S71.04 standard), CE certification for on-site installation

Time synchronization supports GPS satellite UTC time (external) or DCS internal TimeKeeper synchronization (internal), with data timestamp accuracy of 10 times/second (minimum scanning interval of 100ms)

2. Support protocols and concurrency capabilities

Protocol name, part number, multiple protocols, concurrent support, same protocol, multiple instances support

Modbus TCP Client K0177AH Yes Yes

Modbus RTU&ASCII Client K0177CV Yes

Triconex ™ TSAA Client K0177DE is

OPC UA Client K0177EC (single instance only)

Is EtherNet/IP Scanner Driver K0177EP

PROFINET IO Controller K0177FU No No (single instance only)

3. Functional specification parameters

Specific numerical values for parameter categories

The maximum execution speed of functional blocks with a processor performance of 16000 blocks per second, and the minimum block processing cycle (BPC) of 100ms

The maximum capacity of a single sequence block is 32KB

IPC connects 200 data source points (providing external data), 30 sink points (receiving external data), and 1 dedicated internal point

OM (Object Manager) can scan a database with a maximum capacity of 28000 points (18000 points when BPC ≥ 200ms, 7500 points when BPC=100ms); The maximum convergence point is 11250 points

Configurable block period of 0.1/0.2/0.5/0.6/1/2/5/6/10/30 seconds, 1/10/60 minutes

Fault tolerant module pairing time is less than 0.5 seconds

Hardware and environmental specifications

1. Core hardware components and parameters

The FDC280 hardware includes four categories: "module", "motherboard", "network adapter", and "terminal component". The key parameters are as follows:

Component type, model/part number, key specifications

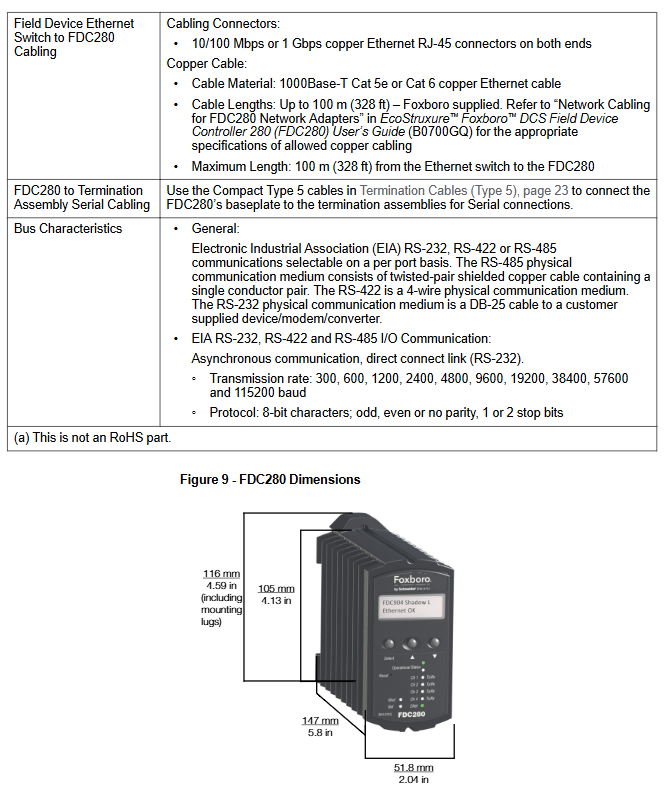

FDC280 module RH101FQ size: height 105/116mm (including installation ears) x width 51.8mm x depth 147mm; single module weight 0.8kg

The base plate RH101KF (2 bits) supports 1 non fault tolerant module or 2 fault tolerant modules, including 2 10/100Mbps/1Gbps copper cable Ethernet RJ45 interfaces, 2 37 pin D-type serial port interfaces, and 2 time synchronization interfaces

Network adapter fiber optic: RH924WA (Rev. E+); Copper cable: RH924UQ (Rev. D+) takes power from the base plate, fiber supports multimode 62.5/125 μ m cable (maximum 2km), copper cable supports Cat5 (maximum 100m)

Serial terminal component ring terminal post: P0926PA; Tightening screws: RH926GH weighs 363g and 272g respectively, and needs to be paired with Type 5 terminal cables (such as RH100HV-1m and RH100HZ-5m)

2. Power and environmental requirements

Category specifications

Power requirement input voltage: 24VDC (redundant,+5%/-10%); The maximum power consumption of a single module is 8.5W

Working temperature -20~60 ℃ (-4~140 ℉)

Storage temperature -40~70 ℃ (-40~158 ℉)

Relative humidity 5%~95% (no condensation)

Altitude operation: up to 3000m; storage: -300~12000m

Anti pollution level Class G3 (ISA S71.04), supports 10-year mixed gas exposure testing (EIA 364-65A Class III), module with conformal coating (conformal coating: protective coating)

Vibration resistance 0.5g (5~500Hz)

3. Compliance certification

Electromagnetic Compatibility (EMC): Compliant with Directive 2014/30/EU, EN 61326-1 Class A (Emission and Industrial Immunity).

Product safety: UL/UL-C certification (applicable to Class I, Groups A-D, Zone 2), EU Low Voltage Directive (2014/35/EU), ATEX Directive (2014/34/EU, DEMKO Ex nA IIC T4 Gc, applicable to Zone 2).

Environmental compliance: Compliant with the EU RoHS Directive (2011/65/EU and revised versions 2015/863, 2017/2102).

California Proposition 65: Products containing lead and lead compounds may cause cancer or reproductive harm, details can be found at www.P65Warning.ca.gov.

Fault tolerance mechanism and reliability design

The "fault-tolerant" core of FDC280 consists of dual module redundancy, independent diagnosis, and seamless switching, covering the control network, CPU, and I/O levels to ensure uninterrupted processes

1. Three layer fault-tolerant/redundant design

Level fault tolerance/redundancy mechanism switching logic

The dual modules of the control network are connected through the backplane and share control network access (dual switches). Communication messages need to be matched bit by bit by the dual modules before being sent. When a fault is detected, the non faulty module takes over control without process interruption

Core 1 (control core) primary/backup mode, real-time synchronization status. When the primary core fails, the backup core immediately switches to primary dynamic mode

Core 2 (I/O core) independently diagnoses the connection status of dual core devices. When the main core fails and the backup core device is better connected compared to the backup core status, the main core resets and hands over the role

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands