Foxboro ™ DCS Field Device Controller 280(FDC280)

Foxboro ™ DCS Field Device Controller 280(FDC280)

Product Overview and Core Positioning

FDC280 is a distributed and optional fault-tolerant on-site installation controller, with the core function of implementing Foxboro ™ The integration of DCS and field devices does not require additional fieldbus modules (FBM), and it also undertakes process control and alarm tasks. It is mainly positioned as the "field device integration center", which is different from the same type of FCP280 (which does not support PIO bus and focuses on Ethernet/serial protocol integration).

1. Core functions

Device integration: Directly interface with Ethernet/serial field devices that support multiple protocols, collect device data for display, historical storage, and execute control tasks.

Control capability: Built in adjustment control, logic control, timing control, sequence control functions, supporting alarm detection and notification.

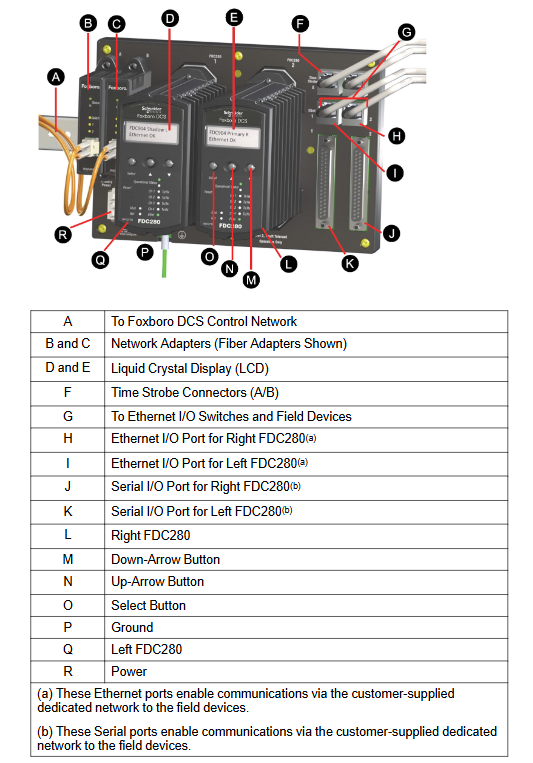

Hardware architecture: Adopting dual core ARM ® SOC processor with clear dual core division of labor:

Core 1 (Control Core): Run control software and DCS control network communication software, supporting fault-tolerant operations.

Core 2 (I/O core): Run device integration software, independently handle on-site device connections and status diagnostics.

Basic requirements: A host workstation with Foxboro DCS Control Core Services v9.3 or higher must be installed, and connected to the control network via 100Mbps fiber/copper Ethernet. It must have obtained ISASecure EDSA Level 1 security certification.

2. Key difference: FDC280 vs FCP280

Comparison item FDC280 FCP280

Core positioning on-site equipment integration (Ethernet/serial port) universal process control

PIO bus support not supported

Core advantage: No FBM required, directly integrated with field devices compatible with traditional PIO bus devices

Network configuration plan

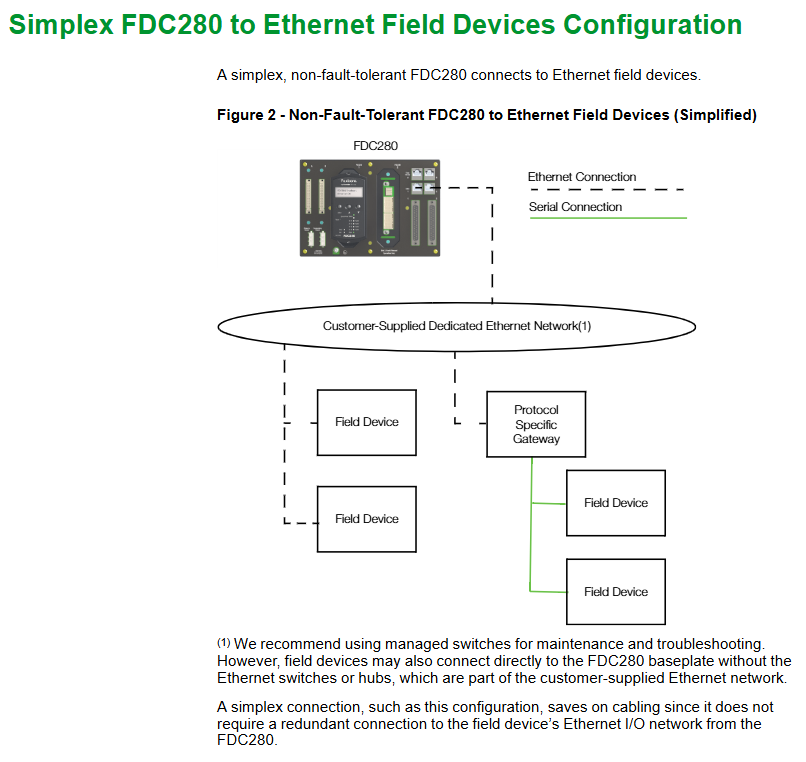

FDC280 supports both Ethernet and serial network configurations, divided into two modes: "simplex" and "fault tolerant", to meet the redundancy requirements of different field devices.

1. Ethernet network configuration

Support direct connection to Ethernet field devices or connection to serial devices through a "protocol specific gateway" (to achieve Ethernet serial bridging), with three core solutions:

Configuration Type Applicable Scenarios Key Features

Simplex, a single FDC280 module for scenarios with low reliability requirements, does not require redundant connections and saves wiring costs

Fault tolerant - Independent network with high reliability requirements, on-site equipment requires independent redundant network dual FDC280 modules (left/right), connected to two independent Ethernet networks provided by customers, with module IP addresses that can be the same or unique

Fault tolerant - Shared network field devices without independent redundancy requirements (such as single port devices). Dual FDC280 modules share one Ethernet network, supporting single port device access and reducing network complexity

Note: It is recommended to use a management switch for easy maintenance and troubleshooting; The device can also be directly connected to the FDC280 motherboard without the need for a switch.

2. Serial port network configuration

Each module of FDC280 contains 4 independently configurable serial ports (supporting RS232/RS422/RS485), with a maximum support of 128 serial field devices (up to 32 devices per RS485 port). The core solution is divided into 2 types:

Non fault-tolerant (Simplex): A single FDC280 can be connected to a single port serial device through a "Terminal Component (TA)", supporting RS485 multi station connection without a modem and RS232/RS422 direct connection.

Fault tolerant type: Dual FDC280 modules are connected to devices through TA and adapted to different port devices:

Dual port device: The left/right module connects the two ports of the device separately to achieve redundant communication.

Single port device: RS232 needs to be connected to two TAs through a Y-shaped cable; RS485/422 can be directly connected through a dual module TA sharing connection.

Core features and performance parameters

1. Key functional characteristics

Specific description of characteristic categories

The device and I/O capacity support a maximum of 256 field devices, 8000 soft I/O points, and 8252 total functional blocks (including Station blocks, ECB components, etc.). Please refer to the FDC280 sizing tool (B0700GS) to calculate the load

The protocol supports 6 core protocols, some of which support concurrent multi instance/multi version (see table below for details)

The diagnostic capability has a built-in "diagnostic driver" that can capture real-time communication messages with the device and send them to the workstation diagnostic application without physical interruption

Fault tolerance mechanism dual module "marriage" operation, Control Network communication requires dual module messages to be matched bit by bit before sending; Core 1 supports primary/backup switching, while Core 2 supports redundancy state comparison and role handover

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands