How to install and wire the Yokogawa FLXA402T turbidity and chlorine liquid analyzer?

How to install and wire the Yokogawa FLXA402T turbidity and chlorine liquid analyzer?

Product positioning

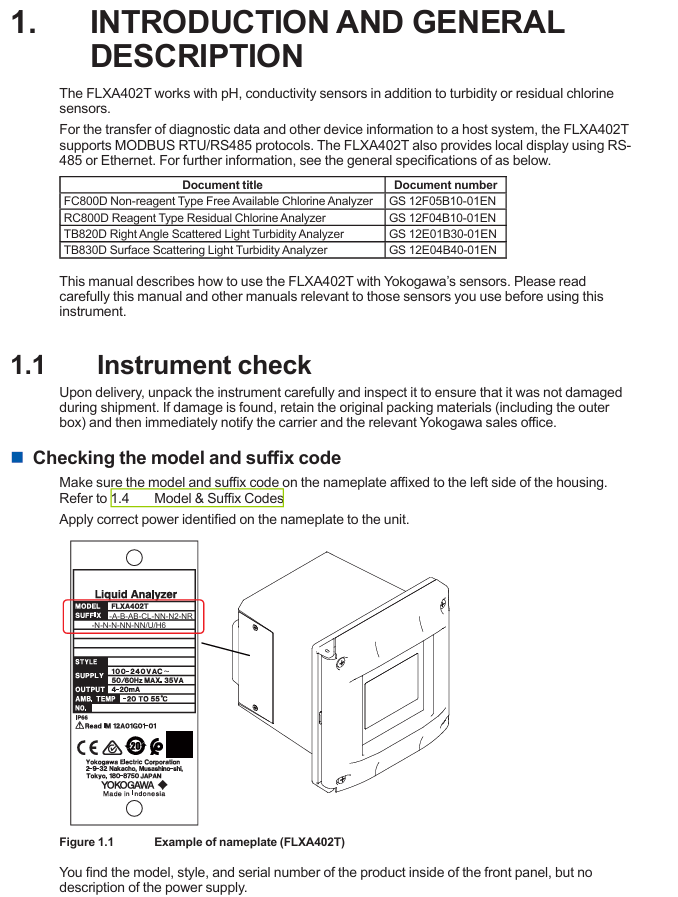

Product type: FLXA402T is a modular design liquid analyzer converter that supports measurement of various parameters such as turbidity (TB820D/TB830D), residual chlorine (FC800D/RC800D), pH value, conductivity (SC), etc. It needs to be used in conjunction with corresponding sensors; Equipped with analog signal output (4-20mA), relay contact output, and digital communication (Modbus RTU/IP) functions, it can upload data to the host system and display locally.

Applicable scenarios: Suitable for industrial process liquid monitoring, supporting indoor and outdoor installation (in accordance with rainproof design), the corresponding sensor module needs to be selected according to the measurement parameters. For example, turbidity measurement needs to be matched with TB series sensors, and residual chlorine measurement needs to be matched with FC/RC series sensors.

Product specifications and model description

1. Core specification parameters

Working environment temperature: -20~+55 ℃ (operation), -30~+70 ℃ (storage); Humidity: 10~90% RH (40 ℃ without condensation)

Waterproof design with protective performance, suitable for both indoor and outdoor use; Outdoor exposure requires a sunshade (/H6/H7 options)

Power supply requirements: AC version (suffix code - A), external 5A or above switch/circuit breaker (compliant with IEC60947-1/3), built-in 250V/2.5A delay fuse (IEC60127 standard)

Communication function supports Modbus RTU (RS-485, suffix - R), Modbus TCP/IP (Ethernet, suffix - E)

Analog IO can choose 2 4-20mA outputs+1 contact input (- N2) or 4 4-20mA outputs+2 contact inputs+1 4-20mA input (- N4), with a maximum load of 600 Ω

Relay outputs 4 sets of SPDT contacts (suffix - WR), including fault safety contacts (S4), configurable for alarm and fault signal output

Grounding requirements: Class D grounding (≤ 100 Ω), protective grounding wire cross-sectional area ≥ 0.75mm ² (CSA certified models 0.75~2.1mm ²)

2. Model and suffix code rules

Model structure: FLXA402T - [Power Supply/Housing] - [First Input] - [Second Input] - [Analog IO] - [Relay Output] - [Digital Communication] - [Other]+[Option Code]. The key code meanings are as follows:

|Code Category | Code Example | Meaning|

|Power supply/enclosure | - A | AC power supply|

|| - B/- D | Aluminum alloy shell (- B: polyurethane coating; -D: High anti-corrosion coating|

|| - AB/- AD | Universal type (- AB: CE/RCM/Chinese standard; -AD: CSA certification)|

|First Input | - CL | SENCOM Protocol Chlorine Sensor (FC800D/RC800D)|

|| - TB | SENCOM Protocol Turbidity Sensor (TB820D/TB830D)|

|Second input | - NN | No second input|

|| - P1/- C1 | pH Sensor/Conductivity (SC) Sensor|

|Analog IO | - N2/- N4 | 2-channel output+1-channel input/4-channel output+2-channel input+1-channel input|

|Relay output | - WR/- NR | with contact output (cleaning/range/fault)/no contact output|

|Digital Communication | - N/- E/- R | No Communication/Ethernet (Modbus TCP/IP)/RS-485 (Modbus RTU)|

|Option code |/U//PM | Universal installation kit (including pipeline/wall installation)/panel installation hardware|

||/H6/H7 | Stainless steel sunshade/Stainless steel+polyurethane coated sunshade|

||/CB4//CD4//CF4 | Catheter adapter (G1/2 x 4/1/2NPT x 4/M20 x 1.5 x 4)|

3. Standard and optional accessories

Standard accessories: Cable gland (M20 × 1.5, 8 pieces, Ethernet version includes 1 black Ethernet gland), rubber plug (5 pieces), pH module gasket set, SENCOM module sealing ring, jumper (for pH/RS-485), starter manual (IM 12A01G01-01EN).

Optional accessories: Pipe/wall/panel mounting bracket (/U//PM), sunshade (/H6//H7), conduit adapter (/CB □//CD □/CF □), stainless steel label (/SCT), spare fuse (A1633EF), industrial SD card (A1019NL, 2GB and above).

Installation process and requirements

1. Preparation before installation

Environmental requirements:

Avoid severe vibrations and strong electromagnetic interference (keep away from relays/power switches), and reserve space for cable connections;

Outdoor installation should avoid direct sunlight (when there is no sunshade), and high anti-corrosion coating shell (- D) should be selected for corrosive environments;

The installation surface should be able to withstand a weight of ≥ 8kg (wall installation), and the pipeline installation should be compatible with a nominal 50A pipeline (outer diameter 60.5mm).

Tools and accessories: Prepare torque wrenches (for tightening seals/panel screws), wire strippers, M3/M4 screwdrivers, as well as standard cable seals, jumpers, gaskets, etc.

2. Detailed explanation of installation method

(1) Panel installation (required/PM option)

Drill holes on the panel according to the size (138 × 195mm, tolerance 0+1mm);

Insert the analyzer into the opening and use the matching panel mounting hardware (K9703ZD) to fix it from the inside of the panel. The torque of the four mounting screws is 2N · m.

(2) Wall installation (required/U option)

Drill 3 M8 screw holes on the wall (positioned according to the bracket holes);

Fix the wall bracket (K9703SS) to the wall with M8 bolts, and then use 4 screws to secure the analyzer to the bracket with a torque of 2N · m.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands