Schneider Electric Foxboro ™ DCS FPS480-24 Compact Power Supply

Relay alarm: The "DC OK" normally closed (NC) relay contacts close when the output voltage is greater than 80% of the rated value, and disconnect when it is less than 80% (such as short circuit, overload, or no input power). External alarm can be triggered by external modules such as FBM207b. The rated load of the relay contacts is 30V DC/1A, 110V DC/0.3A, 125V AC/0.5A, with insulation strength of 1000V AC (between contacts) and 1500V AC (between coils and contacts).

Environment and Compliance

(1) Environmental tolerance

Environmental indicators, operating range, storage range

Temperature -25~70 ° C (-13~158 ° F), linear load derating at 60-70 ° C -40~70 ° C (-40~158 ° F)

Relative humidity 5-95% (no condensation) 5-95% (no condensation)

Altitude -300~3000m (-1000~10000ft) -300~12000m (-1000~40000ft)

Vibration<19.6m/s ² (2G)-

(2) Electromagnetic Compatibility (EMC) and Safety Certification

EMC compliance: Compliant with IEC/EN 60950, UL60950-1, UL508, Semi F47 (only 200V AC) and other standards, with conducted emission (EN55022-B/CISPR22-B), radiated emission (EN55022-B/CISPR22-B), harmonic current (IEC61000-3-2 Class A) and other indicators meeting standards. Anti interference capabilities include: 8kV contact discharge/15kV air discharge (ESD), 2kV electrical fast transient (EFT), 2kV line to ground/4kV line to neutral lightning surge, 10V conducted RF common mode interference, etc.

Safety certification: UL file number E45026, CSA file number LR35579; ATEX certification (Ex nA IIC T3), CENELEC certification, meeting the requirements for use in hazardous areas; California Proposition 65 Warning: Products containing lead and lead compounds may cause cancer or reproductive harm. For more information, please refer to www.p65warnings. ca.gov.

Accessories and Connection Configuration

(1) Core accessory model

Accessory name, model, and purpose

The RH101CR core power supply unit of the power host provides 24V DC/20A output

AC input terminal block cable -1 cable is required to connect the terminal block to the power host

Connect the power supply to the Compact/Standard 200 series motherboard using RH100DY (3.7m), RH100DZ (0.6m), and RH100EA (1.0m) cables, with 14AWG supporting 20A current

DC distribution component RH101BY is used for multi board connection to achieve power distribution

Bottom board power cable (distribution component to bottom board) RH100EB (2.1m), RH100EC (3.0m) 18AWG, directly connecting the distribution component to the bottom board, supporting up to 2 bottom board direct connections

(2) Connection precautions

If only 1-2 base plates are connected, RH100EB/RH100EC cables can be directly used; If more than 2 baseboards are connected, power must be distributed through the RH101BY distribution component to avoid current overload.

It is recommended to use an independent power supply for external on-site equipment to avoid non system loads affecting the stability of DCS system power supply; All wiring must be fastened with M3 screw terminals to ensure reliable contact.

Key points for use and maintenance

Calibration requirements: The power supply is pre-set with a 24.0V DC output at the factory, which does not require user calibration or voltage adjustment, reducing maintenance workload.

Fault handling: After shutting down due to overvoltage/overcurrent, the input power supply should be disconnected first (within 30 seconds), and load faults (such as short circuits and overloads) should be checked before powering on again to restore power; When the "DC OK" relay is disconnected, it is necessary to check whether the output voltage is less than 80% of the rated value (19.2V DC), and troubleshoot input power supply, load, or internal power supply faults.

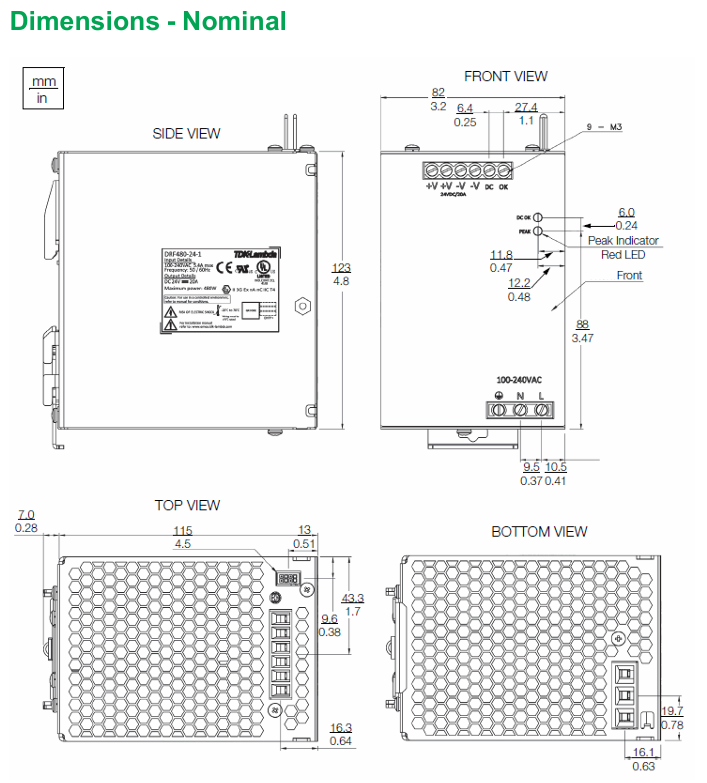

Installation spacing: To ensure natural convection heat dissipation, a ventilation gap of at least 76.2mm (3.0in) should be reserved around the power supply to avoid installation in close proximity to heating equipment.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands