GE Multilin 469 Motor Protection System

GE Multilin 469 Motor Protection System

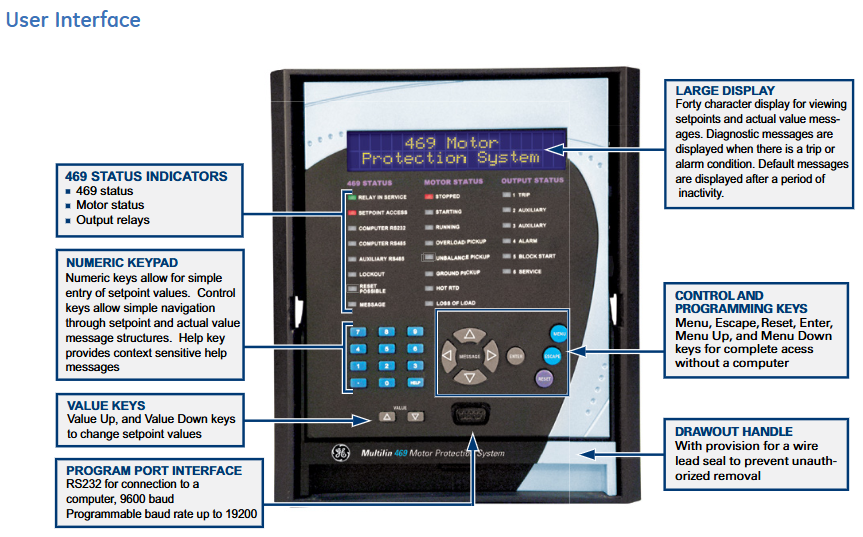

Product positioning and core values

The GE Multilin 469 motor protection system belongs to the SR relay family and is an integrated protection and management device designed specifically for medium and high voltage, large and medium-sized motors. It adopts a pull-out structure, balancing cost-effectiveness and industry-leading flexibility. Its core positioning is to provide comprehensive protection, precise control, simplified configuration, and advanced communication functions for medium and large three-phase motors (including high inertia, dual speed, and step-down starting motors), suitable for safe operation and management of motors and driving equipment in industrial scenarios. It can adapt to different motor characteristics through customized overload curves, single CT differential protection, and other functions. At the same time, with the help of motor parameter auto configurator, multi communication protocol compatibility, and other features, deployment and operation costs can be reduced, and equipment availability can be improved.

Core functions and protective features

(1) Comprehensive motor protection function

Hot model protection (core protection mechanism)

Multidimensional thermal management: integrating six core elements: overload curve (standard/customized/voltage dependent), negative sequence current bias (compensating for additional rotor heating), cold and hot safety stagnation ratio (defining the steady-state thermal capacity utilization rate of the motor), cooling time constant (distinguishing the heat dissipation rate during operation/shutdown), startup suppression and emergency restart (preventing startup when the thermal capacity is insufficient), RTD bias (combined with stator RTD temperature correction thermal model), updating the thermal capacity utilization rate (TCU) every 0.1 seconds, accurately simulating the actual thermal state of the motor.

Overload Curve Characteristics: Provides 15 standard overload curves (multiplier 1-15). The voltage dependent curve is suitable for high inertia loads and can dynamically adjust the thermal overload curve during the acceleration phase according to the system voltage, avoiding motor overheating caused by acceleration time exceeding the safe dead time.

Fault and abnormal working condition protection

Electrical fault protection: covering stator differential protection (supporting 6 CT external summation or 3 flux balanced CT connection, distinguishing the tripping threshold for startup/operation status), short circuit protection (removing the DC component of fault current, supporting secondary tripping backup when the fault is not cleared), grounding fault protection (supporting zero sequence CT, high sensitivity CT, phase CT residual connection, dual tripping/alarm threshold).

Abnormal working condition protection: including mechanical jamming (detecting rotor stalling, locking during startup), acceleration time monitoring (preventing abnormal long acceleration process), undervoltage/overvoltage (independent threshold during motor startup/operation phase, supporting locking in case of VT fuse failure), underfrequency (adjustable from 20-60Hz), over torque (adjustable from 1.0-999999.9 Nm/ft lb, only induction motor alarm), current imbalance (detecting negative sequence current ratio, including phase failure detection algorithm, dual trip/alarm threshold), etc.

Temperature and hardware protection

RTD Temperature Monitoring: Supports 12 programmable RTD inputs (compatible with Platinum 100, Nickel 100/120, Copper 10, etc.) to monitor stator, bearing, and ambient temperature. Each RTD includes three levels of thresholds: alarm, high alarm, and trip. Supports RTD trip voting and open/short circuit fault alarm.

Other hardware protections: including reverse power (to prevent motor from generating electricity due to reverse dragging), underpower (to detect load loss), abnormal power factor (synchronous motor out of step detection), limit on starting times/starting intervals (to prevent excessive starting losses), etc.

(2) Control and configuration functions

Flexible control mode: supports dual speed motor protection (independent overload curve), voltage reduction start monitoring (transition current/time control), frequency conversion filtering (suitable for accurate acquisition of analog signals in VFD scenarios), analog input differential calculation (dual drive system application), trip coil monitoring, etc., to meet the control requirements of different starting modes and operating scenarios.

Simplified configuration tool: equipped with a motor parameter auto configurator, complete parameter settings through a 6-step guided operation; Support on-site firmware and parameter upgrades, with optional conformal coatings for chemical corrosion/humid environments to enhance equipment adaptability.

Monitoring, measurement, and diagnostic capabilities

(1) High precision measurement function

Electrical parameter measurement: Real time monitoring of phase current, differential current, grounding current, average current, current imbalance, phase voltage/line voltage, average voltage, frequency, as well as active/reactive/apparent power, power factor, electrical energy (Wh/var), torque, demand value, etc., with measurement accuracy of ± 0.5% (when current<2 times CT) and ± 1% (when current>2 times CT).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands