Honeywell Expert LS I/O System

Honeywell Expert LS Series A I/O System: Complete I/O from Rack to Rail

In the field of process control, the reliability, flexibility, and environmental adaptability of I/O systems directly determine the success or failure of automation projects. The Series A I/O system in Honeywell's Expert LS platform is an ideal choice for small and medium-sized process control systems due to its modular architecture, rich signal types, multi network integration capabilities, and rigorous explosion-proof certification. This article is based on the "Expert LS I/O Specifications and Technical Data (EP03-110-400)" technical manual, and provides a systematic technical analysis of the Series A I/O system from five dimensions: system architecture, hardware modules, communication integration, hazardous area applications, and engineering planning.

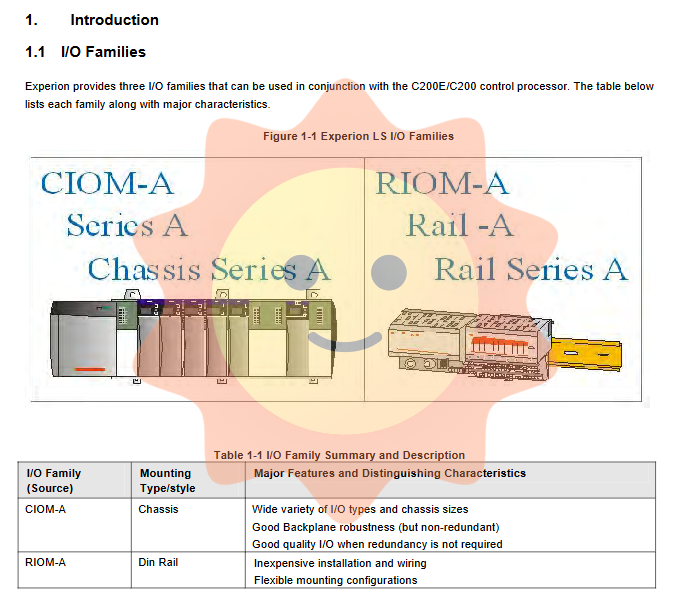

System Overview: CIOM-A and RIOM-A Dual Platform Collaboration

The Expert LS Series A I/O includes two product series, each targeting different physical deployment scenarios:

1. CIOM-A (Rack mounted I/O)

Installation method: Standard rack installation, available in slots 4, 7, 10, 13, and 17.

Core features: High density, high reliability, module adopts single width/double width size, powered and communicated through backplane.

Applicable scenarios: Control rooms or centralized cabinets with high requirements for redundancy and scalability.

Power supply: Dedicated non redundant or redundant power modules (TC-FPCxx2/TC-FPDxx2 and TC-RPCxx1/TC-RPDxx1), mounted on the left side of the rack and not occupying any slots.

Coating options: Model prefix TC (uncoated)/TK (three proof coating), the latter is suitable for corrosive environments of G2/G3 grade.

2. RIOM-A (Rail mounted I/O)

Installation method: DIN rail installation, expanding up to 8 I/O modules through the ControlNet gateway (TC-FCCN01 non redundant/TC-FCCR01 redundant).

Core features: Distributed deployment, simple wiring, flexible installation, support for horizontal/vertical installation and bus extension cables.

Applicable scenarios: on-site distributed I/O, device level control, and renovation projects.

Power supply: External 24VDC power supply (TC-FFPCX1) or power supply through terminal block.

The two platforms can coexist in the same I/O ControlNet network, and achieve seamless integration of centralized and distributed scheduling through C200E/C200 controllers.

CIOM-A Rack mounted I/O: Modular High Density Control Core

1. Rack and power system

Rack model: TC-FXX042/072/102/132/172 (numbers indicate number of slots), corresponding width of 263-738mm, weight of 0.75-2.2kg.

Power specifications:

Non redundant (TC-FPCxx2 AC/TC-FPDxx2 DC): Input 85-132/170-265VAC or 19.2-32VDC, total output power 70W@60 At ℃, the backplane outputs 1.2V/3.3V/5.1V/24V.

Redundancy (TC-RPCxx1/TC-RPDxx1): Dual power supply+rack adapter (TC-RPSCA2), total power 75W@60 ℃, equipped with current sharing, fault alarm, and LED indication.

Power calculation: The power consumption of each module is detailed in Table 7-1 of the manual, and it is necessary to ensure that each voltage bus does not exceed the limit (such as 5V bus limited to 10A).

2. Essentials of Standard I/O Module Specifications

Module model type Channel number Key parameters Terminal type

TC-IAH061 high-level analog input 6 ± 10V/4-20mA, 16 bit, isolated 20 pin TC-TBNH

TC-IXL062 thermocouple input 6 supports B, E, J, K, R, S, T, N, C, D, L, 16 bits, accuracy 0.1% 20 pin TC-TBNH

TC-IXR061 RTD input 6 Pt/Ni/Cu, 16 bits, 0.1% accuracy 20 pin TC-TBNH

TC-ORC081 relay output 8NO+8NC 2A@240VAC , 2A@30VDC , with a lifespan of 300000 cycles and 36 needles TC-TBCH

TC-ODK161 AC output 16 74-265VAC, 2A/point, zero crossing, isolated 36 pin TC-TBCH

TC-ODJ161 DC output 16 24VDC, 2A/point (derating), isolated 36 pin TC-TBCH

TC-HAI081 HART analog input 8 4-20mA/HART, 16 bit, point-to-point 36 pin TC-TBCH

TC-HAO081 HART analog output 8 4-20mA/HART, 15 bits, open circuit detection 20 pin TC-TBNH

3. Special function modules

High speed pulse input (TC-MDP081): 8-channel 0-100kHz counting, 2-channel digital output, 32-bit counter, used for flow and speed measurement.

Serial interface (TC-MUX021): 2-channel RS232/RS422/485, supports Modbus RTU, Allen Bradley DF1, requires FTA (MU-TSIM12/MU-TSIA12) and dedicated cables.

Network module:

ControlNet interface (TC-CCN01/CCR01): single/dual media, 5Mbps, used for C200 and remote I/O communication.

DeviceNet Bridge (1756-DNB): Allen Bradley product, single slot, configured through RSNetWorx.

PROFIBUS DP Master Station (SST-PFBCLX): Made by SST, single width module, supports DP-V1, maximum 496 byte input/492 byte output.

4. Wiring scheme

Option 1: Directly plug and unplug the terminal block (20 pin TC-TBNH/36 pin TC-TBCH) with a wire diameter of 14-22AWG.

Option 2: Remote Terminal Board (RTP), using Allen Bradley 1492 series pre connected cables (1492-HWCAB/HWACAB) to achieve fast connection between IOM and RTP. RTP supports various types such as IFM/RIFM/AIFM/RAIFM/XM, and can support up to 10A relay expansion.

RIOM-A Rail mounted I/O: Pioneer in Distributed Flexible Deployment

1. System composition

ControlNet gateway: TC-FCCN01 (non redundant)/TC-FCCR01 (redundant), occupying 1 node address and driving up to 8 I/O modules.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands