How to troubleshoot Yokogawa OR8EFG KCl filled ORP sensor (IM12C07J01-01E)?

Explosion proof area: After wiring, it is necessary to confirm that the terminal box is sealed properly to prevent flammable gases from entering, and the grounding resistance should be ≤ 1 Ω.

Operations and Calibration

1. Daily maintenance

(1) KCl solution supplementation

Universal Liquid Storage Tank (- TT1): When the remaining solution is less than 1/4, replace with a new liquid storage tank (accessory K9084KQ), or supplement with a 3.3mol/L solution (246g KCl dissolved in 1L pure water) prepared with KCl powder (K9020XU) to avoid reference electrode failure caused by an empty liquid storage tank;

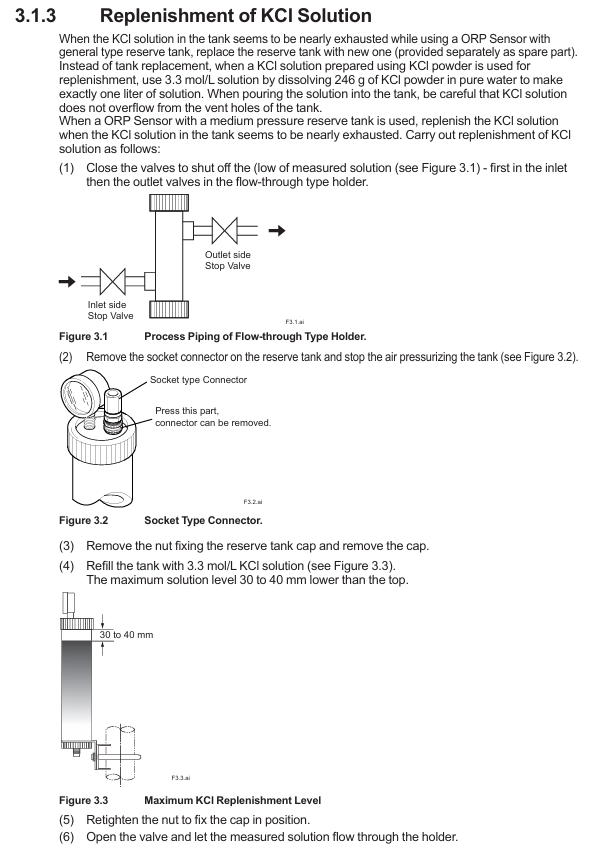

Medium pressure storage tank (- TT2): Close the process pipeline valve → Remove the pressure of the storage tank → Add KCl solution to the specified height → Re pressurize (slightly higher than the process pressure) → Open the process valve, and the replenishment cycle depends on the consumption (usually 1-2 months).

(2) Cleaning of electrode and liquid interface

Choose the cleaning method based on the type of medium contamination, only clean the sensor tip (to avoid damaging the cable/reservoir):

Suspended solids/viscous pollutants: Wipe with a soft tissue and rinse with pure water;

Oil/organic matter: Soak in neutral detergent solution (for tens of minutes to several hours), then rinse with pure water;

Metal adsorption/chemical stains: Soak in 1-2% dilute hydrochloric acid solution (several minutes), then rinse with pure water;

Liquid junction blockage: If the measurement response slows down, the liquid junction can be immersed in a 3mol/L KCl solution at 70 ℃ and naturally cooled to restore conductivity.

2. Calibration process

ORP sensors need to be calibrated regularly with quinone hydroquinone standard solution to ensure measurement accuracy. It is recommended to calibrate every 3-6 months (shortened for severe pollution scenarios):

(1) Calibration preparation

Prepare quinone hydroquinone powder (accessory K9024EC), pH buffer solution (such as pH 4.01/6.87), pure water, and clean the beaker;

Prepare standard solution: Dissolve 1g of quinone hydroquinone powder in 200mL of pH buffer and stir until saturated;

Clean the sensor: Follow the above cleaning method to clean the interface between the indicator electrode and the liquid, rinse with pure water, and dry dry.

(2) Two point calibration steps

First point calibration (pH 6.87 buffer solution):

Immerse the sensor in a quinone hydroquinone pH 6.87 standard solution and wait for the reading to stabilize (usually 5-10 minutes);

Enter the "ORP Calibration" mode according to the transmitter manual (such as FLXA202), and input the theoretical value (ORP=96 mV, rH=23.6 at pH 6.87);

Second point calibration (pH 4.01 or 9.18 buffer solution):

Rinse the sensor with pure water, immerse it in a quinone hydroquinone solution of another pH, and wait for it to stabilize before inputting the corresponding theoretical value (such as ORP=265 mV at pH 4.01);

Verification and reset: After calibration, immerse the sensor in pure water, confirm that the reading drift is ≤± 10 mV, and install it back into the process pipeline.

3. Replacement of vulnerable parts

(1) Liquid interface replacement

When the liquid interface is severely blocked (still unresponsive after cleaning) or damaged, it needs to be replaced (accessories K9142TH/TH, etc.):

Drain the KCl solution from the sensor and unscrew the old liquid interface counterclockwise;

Apply a small amount of KCl solution to the new liquid interface and gently screw it into the sensor body 2-3 times;

Refill the KCl solution until it overflows, tighten the liquid interface, and confirm that the solution seeps out from the liquid interface (visually or through a transmitter to detect impedance 2 ≤ 50 k Ω).

(2) Indicator electrode replacement

If the electrode surface is severely oxidized (with large reading drift and slow response), replace the platinum/gold electrode (accessory K9142TS/TT, etc.):

Remove the old electrodes from the sensor body and check if the O-ring is damaged (replace them together);

Apply silicone grease to the new electrode O-ring and screw it clockwise into the installation hole until it is sealed;

Refill KCl solution, calibrate and put into use.

Troubleshooting and spare parts

1. Common faults and solutions

Possible causes and solutions for the fault phenomenon

ORP reading drift is large. 1. KCl solution depletion/contamination; 2. Blockage at the liquid interface; 3. Indicate electrode oxidation; 4. Poor grounding; 1. Supplement/replace KCl solution; 2. Clean/replace the liquid interface; 3. Clean or replace the electrode with hydrochloric acid; 4. Check that the grounding resistance is ≤ 1 Ω;

Slow response speed: 1. Blockage at the liquid interface; 2. The sensor is installed in the dead zone (no medium flow); 3. Poor cable contact; 1. Use hot KCl solution to regenerate the liquid interface; 2. Adjust the installation position to the location where the medium flows; 3. Check if the cable wiring is loose;

Reading no response 1. Electrode breakage (cable core wire breakage); 2. The transmitter has no power supply; 3. The liquid interface is not filled with KCl; 1. Measure the electrode resistance with a multimeter (about 10 Ω at room temperature for platinum electrodes), and replace the cable if it breaks; 2. Check the power supply of the transmitter; 3. Refill KCl solution;

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands