How to ensure the safety and maintenance of YOKOGAWA LS3300 AC power calibrator?

How to ensure the safety and maintenance of YOKOGAWA LS3300 AC power calibrator?

Product basic information

1. Product positioning and core functions

LS3300 is an AC power calibrator that uses the "phantom load method" to generate AC voltage, current, and power signals. It is mainly used for calibrating power meters and other equipment, supporting multiple wiring systems and synchronous operations to meet calibration needs in different scenarios.

2. Manual system and language version

Supporting manual: In addition to this manual, it also includes Chinese specific documents (IM LS3300-92Z1), European language safety manual (IM 00C01C01-01Z1), and global contact list (PIM 113-01Z2).

Language code: The "EN" in the manual number represents English, and "Z1" represents other languages such as Chinese. Users can obtain the corresponding version according to their needs.

Manual update: The content may change without prior notice due to product performance/feature upgrades. The latest version should refer to the official website; As of April 2025, it is the 8th edition, and the historical version gradually iterates from the 1st edition in August 2017.

Preparation before use

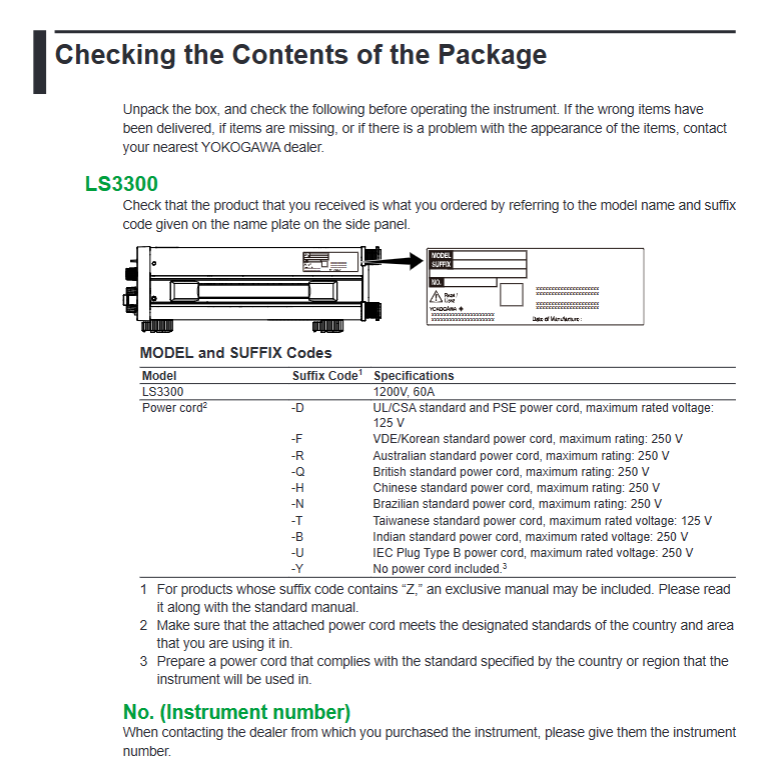

1. Packaging content inspection

Host and identification: Confirm that the host model is LS3300 (specification 1200V, 60A), and verify the model and suffix code through the side panel nameplate to avoid misdelivery.

Standard accessories: including 1 power cord with matching suffix code (such as - H for Chinese standard, - Q for British standard, etc., - Y without power cord needs to be provided), measuring wire (B8506ZK/B8506WA), crocodile clip adapter set, rubber foot cap, and complete manual. Confirm that the accessories are intact.

Optional accessories: Measurement wire, crocodile clip adapter, BNC cable, rack installation kit, etc. need to be purchased separately, and the selection needs to match the rated parameters of the equipment (such as 758917 measurement wire rated 1000V, 32A).

2. Installation and power connection

Installation requirements: It should be installed in a well ventilated area, with sufficient space reserved for the top/bottom air outlet and rear air inlet (top/bottom ≥ 20cm), avoiding direct sunlight, humidity, strong magnetic fields, and other environments; Supports desktop placement (adjustable movable feet) or rack installation (requires specialized kit), and is prohibited for outdoor or water environments.

Power specifications:

Rated voltage: 100-120VAC or 200-240VAC, allowable fluctuation range 90-132VAC, 180-264VAC, frequency 50/60Hz (allowable fluctuation range 48-63Hz).

The power cord must be designed specifically for the device and comply with local standards (such as the - H type used in China, rated at 250V). It must be plugged into a three hole socket with protective grounding. It is prohibited to cut off the grounding wire or use ungrounded extension cords.

Core functions and operations

1. Output parameter settings

(1) Voltage output setting

Range and Range: Supports ranges of 1V, 10V, 30V, 100V, 300V, and 1000V, with an output range of 0-125% of each range (set by "output level x level ratio", level ratio 0-120%). For example, a 10V range can output a maximum of 12.5V.

Key parameters: frequency 40-1200Hz, phase -180 ° to+359.999 °, power factor -1.0 to 1.0 (lead/lag can be set); When the voltage is ≥ 150V, a buzzing warning will be issued, and when the range is ≥ 300V, the "high voltage indicator light" will light up.

(2) Current output setting

Range and Range: The basic range is 30mA, 100mA, 1A, 10A, 50A, and can be extended to 20A, 30A, 100A, 150A when synchronizing multiple devices; Supports "external sensor mode" (500mV/5V output, voltage current conversion ratio needs to be set), with the same output range as the voltage logic (0-125% range).

Key parameters: Frequency, phase, power factor settings should be consistent with voltage. For high current outputs (such as 20A and above), the wiring system should be set to "1P2W (HI Current)" and multiple devices should be synchronized.

(3) Scanning function (Sweep)

Function purpose: By linearly adjusting the level ratio, the output can smoothly change within a specified range (such as checking for meter pointer sticking), supporting separate scanning of voltage/current.

Parameter settings: Scanning range 0-100%/105%/110%/120% (relative to output level), scanning time 8s/16s/32s/64s (time from 0% to 100%), can be set to "UP" or "DOWN", and will automatically hold when reaching the limit value.

2. Synchronous operation and wiring system

(1) Synchronization function

Multi device synchronization: Supports up to 3 LS3300 devices for synchronization, or synchronization with external devices such as 2558A; The master device is connected to the slave device's "OSC INPUT" terminal through the rear "OSC OUTPUT" terminal, synchronizing frequency and phase (external device synchronization only ensures frequency consistency, phase needs to be manually adjusted).

Synchronization settings: Set the master device to "INTernal" and the slave device to "EXTernal"; The "LINE" mode can also be set to synchronize the output with the power frequency.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands