YASKAWA MP2000 series machine controller communication module

YASKAWA MP2000 series machine controller communication module

The entire process of starting the communication module

Step 1: Prepare using the machine

Essential equipment: MP2000 series controller, communication module, communication partner device, dedicated cable, computer with MPE720 installed

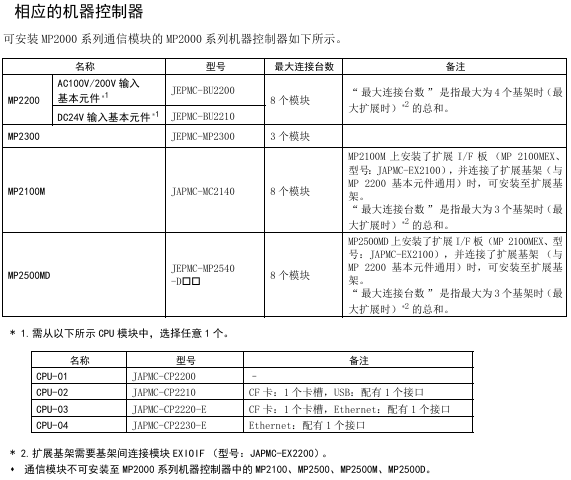

Controller compatibility: MP2200 (JEPMC-BU2200/BU2210, maximum of 8 modules), MP2300 (JEPMC-MP2300, maximum of 3 modules), MP210M (JAPMC-MC2140, expansion board required, maximum of 8 modules), MP2500MD (JEPMC-MP2540-D , expansion board required, maximum of 8 modules)

Step 2: Module installation and disassembly

Installation steps: Power off → Remove the machine controller battery cover → Remove the optional module cover → Align the guide rail and insert the module → Install the cover → Power on

Disassembly steps: Power off → Backup program → Remove cable → Remove battery cover → Remove cover → Use battery cover protrusion to pry module → Pull out module

Step 3: Communication Manager Settings

Supported port types: Serial (RS-232C), Ethernet, Ethernet (LP), CP-215

Key setting example (Ethernet): Set the computer IP to 192.168.1.2 and subnet mask to 255.255.255.0; Set the Logical PT to Ethernet and fill in the computer IP address for the Communication Manager

Step 4: Automatic Configuration Execution

Trigger method: Set "CNFG" to ON and restart MP2200/MP2300; MP210M/MP2500MD operated through the MPE720 menu

Result difference:

CNFG Initiate Results

The ON module has been updated, and all communication modules are configured according to default settings

The ON/OFF module has been updated, with existing modules retaining their configuration and new modules using default settings

Step 5: MPE720 Startup and Transfer Definition

Ver.6: Online → Communications Setting → Select Logical Port → Set Parameters

Ver.5.xx: Start MPE720 → Open PLC folder → Properties → Network → Check OnLine → Select logical port

Transfer definition: Open the module composition definition screen → double-click the corresponding module → set parameters → save to flash memory

Detailed explanation of transmission mode and protocol

Classification of transmission modes

Mode applicable communication mode (module) core characteristics

Information transmission RS-232C (all), Ethernet (218IF-01/02), MPLINK (215AIF-01) event triggered, using MSG-SND/MSG-RCV functions

Engineering transmission RS-232C (all), Ethernet (218IF-01/02), MPLINK (215AIF-01) panel commands+MPE720 for program transmission

Link Transport MPLINK (215AIF-01) regularly sends and receives, only supported by 215AIF-01

Core Communication Protocol

MEMOBU: Yaskawa standard, main controller specifies sub controller address communication, function codes include 01H (read winding), 03H (read hold register), etc., supporting 1-2000 bits (bit data), 1-125 words (word data)

Extended MEMOBU: MEMOBU extension, adding function codes such as 09H (extended read hold register), transmitting 1-508 words at once, supporting MEMOBU/general information mode

MELSEC: Compatible with Mitsubishi A-series, supports communication between CPUs and fixed buffer communication, with function codes corresponding to ACPU universal commands (such as WR → 01H/02H)

MODBUS/TCP: Industrial Ethernet protocol, supports 1-2000 bits (read winding), 1-125 words (read register), 218IF-01/02 automatic conversion protocol

No steps: Directly transfer data from the M register, divided into word (1-254 words) and byte (1-508 bytes) units, with no response

Serial communication (taking 217IF-01 as an example)

Ports and protocols

Interface: RS-232C (PORT, 9-pin), RS-422/485 (14 pin)

Supporting protocols: MEMOBU, MELSEC, OMRON, Stepless, Stepless FD (Full Duplex, Maximum Received 5080 Words)

Transmission definition parameters

Example of Parameter Setting Content

Transmission Protocol MEMOBU/MELSEC/OMRON/Stepless MEMOBU

Master (Address 0)/Slave (Address 1~63) Slave, Address 1

Baud rate 9600/19200bps 19200bps

Data length 7/8 bits 8 bits

Parity Even/Odd/None Even

Connection Example

Connected to MELSEC: RS-232C (pin 2=TXD, 3=RXD) of 217IF-01 connected to Mitsubishi AJ71UC24 (pin 2=RXD, 3=TXD), MELSEC set station number 01, baud rate 19200bps

Connected to frequency converter: RS-485 (pin 3=RX+, 4=RX -, 8=TX+, 9=TX -) of 217IF-01 is connected to VS-616G5, and frequency converter H5-01=1 (address) H5-02=9600bps

Key module characteristics (218IF-01/02, 260IF-01)

218IF-01 module

Interface: RS-232C (PORT), Ethernet (10Base-T, RJ45)

Specification: Ethernet transmission speed of 10Mbps, half duplex; RS-232C maximum transmission 15m

Ethernet settings: IP address (default 192.168.1.1), subnet mask, connection parameters (TCP/UDP, ports 256~65535)

218IF-02 module

Interface: RS-232C (PORT), Ethernet (100Base TX/10Base-T)

Advantages: Supports Ethernet (LP) ports, higher engineering communication speed, maximum transmission of 100m (100Base TX)

260IF-01 module

Communication: DeviceNet, supports Explicit protocol, main controller settings

Specification: Maximum number of nodes 64, transmission speed 125/250/500kbps

Key issues

Question 1: There are two triggering methods for the automatic configuration of MP2000 series communication modules. Which controllers are they applicable to? What are the differences in configuration results?

Answer:

Applicable controllers:

Dial switch trigger: suitable for MP2200 and MP2300, triggered by turning on the "CNFG" toggle switch of the machine controller and restarting the power supply;

MPE720 operation trigger: applicable to MP210M and MP2500MD. After starting MPE720, select Order → Self Configure All Modules/Module Self Configuration on the Module Configuration screen to trigger.

Differences in configuration results:

Specific operation results of triggering method

The dip switch (MP2200/MP2300) CNFG=ON, Initiate=ON module composition definition is updated, and all detected communication modules are configured according to default values

The dip switch (MP2200/MP2300) CNFG=ON and Initialize=OFF modules constitute a definition update. Modules that already have transmission definitions retain their current definitions, while newly detected modules use default values

MPE720 (MP210M/MP2500MD) automatically configures all module composition definitions and updates them. Existing defined modules retain their current definitions, while newly detected modules use default values

MPE720 (MP210M/MP2500MD) automatically configures a single module with only selected module configurations and transmission definitions. Existing definitions are reserved, and newly detected ones use default values

Question 2: What are the core differences in functionality and usage between the IF-01 module, which supports two protocols: Stepless and Stepless FD?

Answer: The core differences between the two are reflected in communication methods, number of channels, data processing capabilities, etc., as follows:

Comparing dimensions without steps or steps FD

Communication method: Half duplex (cannot transmit/receive simultaneously), Full duplex (can transmit/receive simultaneously)

1 information channel (MSG-SND/MSG-RCV dual-use) 2 channels (1 dedicated for sending and 1 dedicated for receiving)

The maximum data size for both sending and receiving is 254 words. Sending 254 words and receiving a maximum of 5080 words (20 buffers, each buffer containing 508 words)

Data exception handling: If one byte in one message is abnormal, all data will be discarded. Only the abnormal byte will be discarded, and normal data will be retained. The exception will be reported to the MSG-RCV function

Wiring requirements: Half duplex wiring (such as RS-485 2-wire system), full duplex wiring (such as RS-485 4-wire system, separate transmission/reception lines)

Suitable for simple one-way communication scenarios that require high-speed simultaneous transmission and reception, such as real-time data acquisition and control

Channel number setting: MSG-SND/MSG-RCV are both set to 1. MSG-SND is set to 1, and MSG-RCV is set to 2

Question 3: The Ethernet communication of the IF-01 module supports two connection types, TCP and UDP. How to choose? What are the precautions for using these two types under a step-by-step protocol?

Answer:

Selection criteria for connection type:

TCP: a connection type protocol that requires the establishment of a connection, supports data confirmation, error retransmission, flow control, and has high communication quality. It is suitable for scenarios that require high data reliability, such as control instruction transmission;

UDP: A connectionless protocol that does not require establishing a connection, has simple processing, fast communication speed, and is suitable for scenarios that require high real-time performance and can tolerate a small amount of data loss (such as real-time status monitoring).

Notes under the Stepless Protocol:

Attention to TCP usage:

TCP is a byte stream protocol, and continuous transmission of data may result in the synthesis of data packets. The receiving side cannot recognize the data boundary and measures need to be taken (such as setting a transmission interval of more than 1 second, establishing command response protocols, and avoiding packet segmentation);

Each connection only has one receive buffer, and before receiving data, the MSG-RCV function is used to read out old data to avoid new data overwriting old data.

UDP usage precautions:

No connection confirmation, sending to a non-existent socket will result in an error. It is necessary to ensure that the other party's device is online and the port is correct;

The receiving interval should be greater than twice the execution period of the MSG-RCV function (if the function period is less than 5ms, the sending interval should be set to 12ms or more) to avoid data coverage.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands