SCHNEIDER Modicon Quantum Automation Series

Deep analysis of hardware for SCHNEIDER Modicon Quantum automation system

Introduction: System Overview

The Modicon Quantum automation system under Schneider Electric is a classic platform in the field of industrial control, known for its high modularity, powerful processing capabilities, and flexible configuration. This system is designed specifically for demanding mid to large scale automation applications, covering process control, manufacturing automation, and infrastructure management. This manual serves as an authoritative reference guide for its hardware, detailing the complete hardware ecosystem from the core processing unit to the outermost signal interface. This article is based on the core content of the manual, aiming to extract and integrate its key technical information, providing a clear and in-depth professional interpretation for automation engineers, system integrators, and maintenance personnel.

Part 1: System Architecture and Configuration Philosophy

The core advantage of Quantum system lies in its flexible physical and logical architecture. It supports three main I/O configuration modes to adapt to application scenarios of different sizes and complexities:

Local I/O configuration: The CPU module and I/O module are directly installed on the same backplane and communicate through a high-speed backplane bus. This method has the lowest delay and is suitable for critical control loops that require extremely high real-time performance.

Remote I/O configuration: By using dedicated remote I/O communication modules, I/O racks are distributed within a range of several hundred meters to several kilometers from the CPU. The RIO network uses coaxial cables or optical cables to form a master-slave network, greatly expanding the physical coverage range of the system.

Distributed I/O configuration: Based on open fieldbus protocols such as Profibus DP, DeviceNet, etc., third-party or dedicated distributed I/O stations are connected to the Quantum system through DIO modules. This achieves deep integration and interoperability at the device layer.

At the network level, the Quantum system natively supports Modbus, Modbus Plus, and industrial Ethernet. The Modbus Plus network provides deterministic peer-to-peer communication capabilities, while the Ethernet module supports protocols such as TCP/IP and MMS, seamlessly connecting to the enterprise information layer.

Part 2: Detailed Explanation of Core Module Technologies

1. Power module: the foundation of system stability

The power module provides isolated and stable DC power for the entire rack. The manual provides a detailed list of various models ranging from 3A to 11A, AC (115/230V AC) to DC (24V/48V/125V DC), including standard, parallelizable, and redundant models. The redundant power supply design ensures the continuous operation of the system in the event of a single power failure, with key parameters including input voltage range, output power, ripple noise, and heat dissipation characteristics. The correct selection and calculation of power supply is the first step in system reliability.

2. CPU module: controls the brain

The CPU module is the computational and control core of the system. Different models of CPUs have differences in memory capacity, processing speed, number of communication ports, and supported programming functions. The manual lists multiple series from basic to high-performance (such as 140CP43412A), which support multiple IEC 61131-3 programming languages such as ladder diagrams and structured text, and have powerful data processing and network communication capabilities.

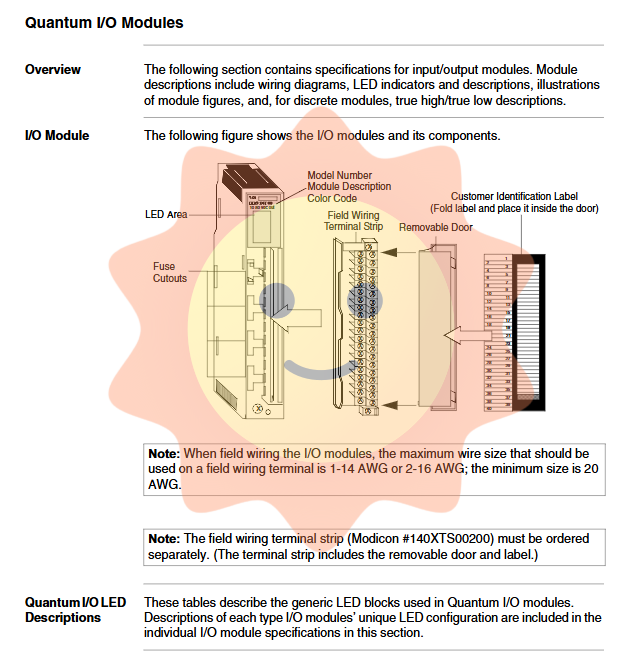

3. I/O module: interface with the world

I/O modules are the most abundant component of Quantum systems, divided into two categories: analog and digital.

Analog I/O module:

Analog input module: such as 140AVI03000 (8-channel, bipolar), supporting multiple signal ranges such as ± 10V and ± 20mA, with 16 bit resolution and high common mode rejection ratio. Its key features include configurable input types for each channel, wire breakage detection (for 4-20mA signals), and over/under range alarms. Thermistor and thermocouple modules (such as 140ATI03000) have built-in cold junction compensation and high-precision analog-to-digital conversion, which can be directly connected to temperature sensors.

Analog output module: such as 140AVO02000 (4-channel voltage output) and 140ACO02000 (4-channel current output), providing 12 bit resolution, the output can be configured to maintain the last value or jump to a preset safe state. The current output module has an open circuit detection function.

Digital I/O module:

Digital input module: voltage levels range from 24V AC/DC to 230V AC, and even 125V DC. The module design distinguishes between "current pouring" and "current pulling" types to match the output type of on-site equipment. For example, 140DDI35300 is a 24V DC input used to connect "source type" output devices. The high-speed module supports millisecond level response.

Digital output module: also covers a wide range of voltage and current levels. The relay output module provides electrical isolation and is suitable for driving low-power loads with different voltages; The solid-state AC output module adopts thyristor technology; The DC output module adopts transistor technology and generally integrates overcurrent protection and surge suppression. Safety Warning: For AC output modules, the manual emphasizes that external fuses must be equipped for each output point, and protective components such as varistors must be added when parallel inductive loads are connected to prevent module damage and ensure safety.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands