SCHNEIDER Modicon Quantum Automation Series

Specialized and intelligent modules:

Including intrinsically safe I/O modules for use in hazardous areas, integrating safety barrier functionality within the module.

Input/output hybrid module, such as 140DAM59000 (16 point AC input/8 point AC output), saves space.

Diagnostic enhancement module, such as 140DVO85300 (verification output module), can read back the output point status to verify the actuator action; 140DSI35300 (monitoring input module) can detect input circuit disconnection.

4. Communication and Expansion Module

The system is interconnected with the upper layer network, other PLCs, and field devices through Profibus DP master module, Ethernet module, Modbus Plus network module, etc. The remote I/O head and adapter module form a stable RIO network backbone.

Part Three: Key Engineering Practices and Safety Guidelines

The extensive safety warnings and engineering guidelines in the manual reflect the rigor of industrial products:

Safety first: The manual begins with three levels of signage: "Danger," "Warning," and "Caution," emphasizing electrical safety, mechanical safety, and equipment safety. For example, before conducting live operations or replacing modules, it is necessary to confirm the safety status; The wiring must comply with national and local regulations.

Installation and grounding: Detailed regulations on module spacing, heat dissipation requirements, backplane selection, and installation torque. Proper system grounding is of utmost importance in suppressing electromagnetic interference, ensuring stable operation, and ensuring personnel safety. The manual requires the use of an independent low impedance grounding bus and avoids common points with the power ground.

Cable and wiring: It is recommended to use shielded cables to process analog signals and high-speed digital signals, and it is specified that the shielding layer should be grounded at a single point. The maximum allowable wire gauge for on-site wiring terminals is 14 AWG.

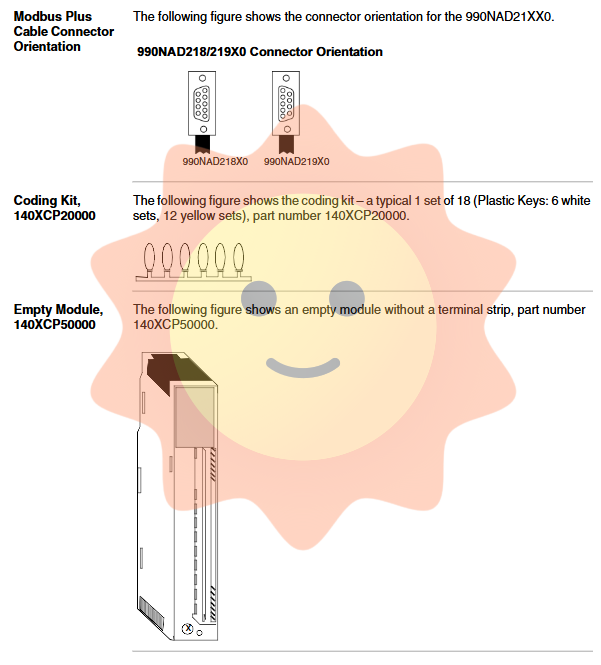

Module coding: To prevent accidental insertion of wired terminal blocks, all I/O modules and terminal blocks support primary/secondary mechanical coding. The main code is predefined by the manufacturer to distinguish module categories (such as 24V DC input), and the secondary code can be customized by the user to distinguish the same module type or identify slot positions.

Software compatibility: Emphasis must be placed on using Schneider official or certified software (such as Concept, Unity Pro) for configuration and programming, as incompatible software may result in unpredictable operations.

Part Four: System Status Monitoring and Fault Diagnosis

The Quantum system provides a sophisticated state monitoring mechanism. In the I/O mapping configuration, a starting address for the state table can be assigned. Each I/O module slot in the system will report its status (8-bit bytes) to this table. The content of the status byte varies by module and may include information such as channel failure, group power loss, communication abnormalities, data overload, etc. By accessing these status words through programming, predictive maintenance and rapid fault location can be achieved. For example, the status byte of the analog module can indicate the disconnection or out of range of a specific channel, while the status byte of the digital output module can indicate that the fuse is blown or overloaded.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands