Zygo NewView 9000 3D Optical Profilometer Technology Advantages

Zygo NewView 9000 3D Optical Profilometer Technology Advantages

Equipment core positioning and technological advantages

1. Core positioning

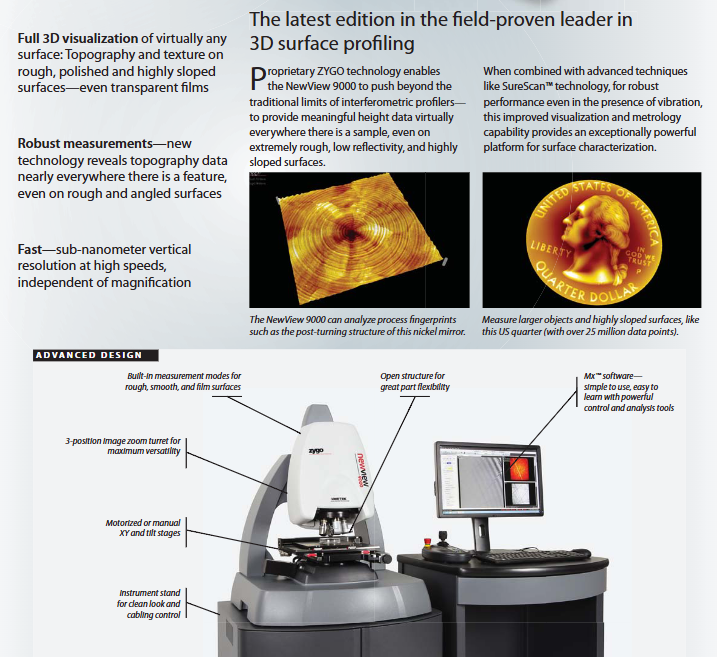

NewView 9000 is a high-end desktop 3D surface profilometer launched by Zygo, which adopts non-contact measurement technology and is designed for "high-precision, wide adaptability, and high robustness" surface characterization. It can cover the full scene measurement requirements from "atomic level smooth surfaces" to "rough microstructure surfaces". Typical applications include surface morphology, texture, and step height analysis of MEMS devices, optical components, precision mechanical parts, etc.

2. Four core technological advantages

The specific manifestation value of technological advantages

Full scene surface adaptation supports 3D visualization of rough, polished, high slope surfaces, and even transparent films;

Samples with low reflectivity (≥ 0.05%) and high slope (smooth surface ≤ 55 °, scattering surface ≤ 85 °) can be measured without sample pretreatment, covering over 90% of micro nano surface measurement requirements

Strong measurement robustness equipped with Zygo patented technology (such as SureScan) ™), Can still maintain accuracy in vibration environments (1-120Hz);

Data collection without blind spots - even if there are complex features on the surface (such as grooves and sharp corners), effective height data can still be generated to adapt to non ideal environments such as workshops and multi device laboratories, reducing measurement failure rates

Balancing high precision and high speed with vertical resolution: sub angstrom level (RMS repeatability 0.008nm), and independent of magnification;

Acquisition speed: Complete full field of view measurement within 1 second in Smart PSI mode, balancing "nanometer level accuracy" and "batch measurement efficiency", suitable for scientific research and industrial quality inspection

High operational convenience, open structure design, convenient sample loading and observation;

The software adopts a "workflow oriented" logic, which can complete complex analysis without professional programming skills, reduce operational barriers, and shorten personnel training cycles

Hardware configuration and performance indicators

1. Core hardware components

(1) Optical system

Specific configuration characteristics of components

Measurement technology: 3D coherent scanning interferometry (CSI)+Smart PSI technology (sub angstrom accuracy)+SureScan ™ Technology (anti vibration) multi technology integration, balancing accuracy, speed, and anti-interference ability

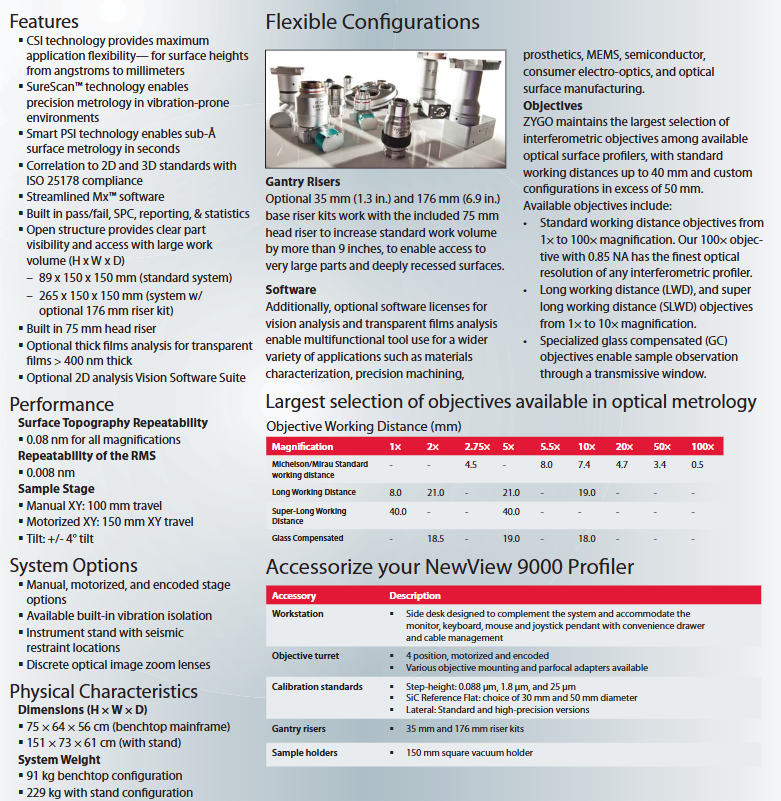

The most comprehensive selection of objective lenses in the objective lens system industry, covering 1 × -100 × magnification and supporting 4 types of objective lens:

1. Standard working distance (e.g. 100 × NA=0.85, optimal optical resolution);

2. Long working distance (LWD, such as 1 x working distance of 8mm);

3. Extra long working distance (SLWD, such as 1 ×/5 × working distance of 40mm);

4. Glass compensation (GC, suitable for samples with transparent windows) adapts to different sample thicknesses and loading methods, such as SLWD objective for thick samples and GC objective for samples with protective windows

Optical zoom comes standard with a 3-digit electric coding zoom turntable (including a 1.0 x zoom tube), with optional 0.5 x/0.75 x/1.5 x/2.0 x zoom components and objective lenses to expand the field of view (0.04 x 0.04mm-17.49 x 17.49mm). The coding design ensures repeatability of zoom positions

Lighting system with white LED light source, equipped with manual field stop, aperture stop, and spectral filter to adapt to different reflectivity samples, adjust lighting intensity and spectrum, and improve data signal-to-noise ratio

(2) Motion and stage system

Stage type XY axis stroke tilt range (Tilt) Core advantages

Manual stage 100mm ± 4 °, low cost, suitable for fixed position measurement

Electric stage (optional) 150mm ± 4 ° supports automated stitching (field of view stitching) and patterned sampling;

Optional "Encoding XYZ" configuration for higher repeatability in positioning

Workplace standard: 89 × 150 × 150mm;

Optional 176mm riser kit: 265 × 150 × 150mm supports large-sized samples (such as 89mm high samples), and the riser kit is suitable for measuring deep cavities and thick samples

(3) Structural and environmental adaptation

Physical dimensions: desktop host 75 × 64 × 56cm, with bracket 151 × 73 × 61cm;

Weight: desktop 91kg, with bracket 229kg;

Vibration isolation: comes standard with a vibration isolation system that meets VC-C level vibration standards (1-120Hz);

Environmental requirements: temperature 15-30 ℃ (rate of change<1 ℃/15min), humidity 5% -95%, no condensation.

2. Key performance indicators (laboratory conditions)

Performance category indicator notes

Surface morphology repeatability at 0.08nm full magnification, suitable for Smart PSI mode+3 × 3 median filtering

RMS roughness repeatability of 0.008nm, also known as' vertical resolution ', reflects the accuracy of surface detail measurement

Field of view range 0.04 × 0.04mm (100 × objective lens+2 × zoom)~17.49 × 17.49mm (1 × objective lens+0.5 × zoom) supports field of view stitching, expanding to a larger measurement area

Step height accuracy of 0.3% (instrument contribution uncertainty) verified using Zygo certified standard parts (0.088 μ m/1.8 μ m/25 μ m)

Software System: Mx ™ Control and Analysis Platform

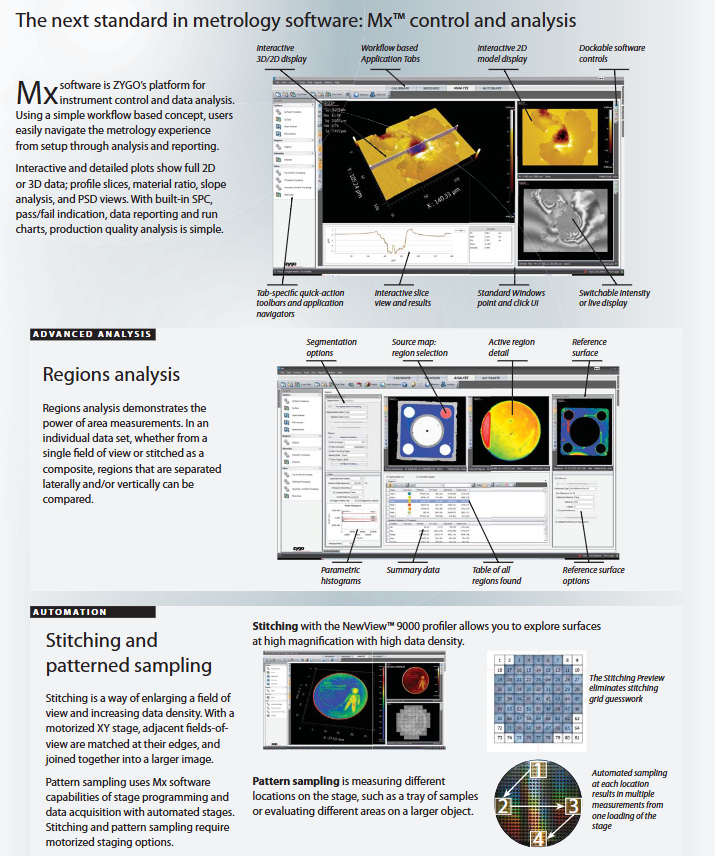

Mx ™ The software is the core operation and analysis tool of NewView 9000, designed with a "workflow oriented" approach that balances convenience and professionalism. Its core functions are as follows:

1. Convenient operation design

Workflow tab: Split "Device Settings ->Sample Positioning ->Data Collection ->Analysis ->Report" into independent tags, beginners can follow the steps to operate;

Visual interaction: supports real-time display of 2D/3D data, can rotate 3D models and zoom in and out of local areas by dragging and dropping with the mouse;

Shortcut keys and toolbar: Each tab is equipped with a "quick operation toolbar" (such as "start collection" and "save data"), which supports Windows standard keyboard and mouse operations without the need to memorize complex commands.

2. Core analytical skills

Analyze the specific application scenarios of the analysis function

Basic morphology analysis includes 2D/3D surface maps, cross-sectional profiles (slices), slope analysis, and power spectral density (PSD);

Automatically calculate key parameters: PV (peak valley value), RMS (root mean square), Ra (arithmetic mean roughness), step height/width, surface flatness, microstructure size detection

Regions Analysis divides a single dataset into multiple regions (horizontally/vertically separated) and compares the morphological parameters of each region;

Support "reference surface selection", "parameter histogram", "data summary table" for multi structure consistency detection of MEMS devices and analysis of local defects in optical components

Automation and quality control have built-in SPC (Statistical Process Control) and pass/fail criteria (based on user-defined upper and lower limits);

Support data export (Excel/PDF/image), generate run charts for industrial batch quality inspection, such as screening for surface shape errors in lens production lines

3. Automation function

Stitching: The electric stage drives the sample to move, collects adjacent field of view data, and automatically splices them to generate a complete morphology image of the large-sized sample (such as the full surface of a 150mm wafer);

Pattern Sampling: preset measurement point array (such as 10 × 10), the stage automatically moves to each point for measurement, suitable for "diversified product tray" and "large sample multi area detection";

Preview function: Stitching Preview displays the spliced grid in advance to avoid overlap/omission and improve splicing efficiency.

Equipment configuration and optional accessories

1. Basic Configuration List

Category Basic Configuration

Desktop structure of the host, including isolation system, white LED lighting, and a 3-digit zoom turntable

Objective lens standard: 1 × -100 × standard working distance objective lens (at least 1, customizable by users)

Manual XY stage (100mm stroke), tilted ± 4 °

Control system i7 processor PC (1080P monitor), Windows 10 system, Mx ™ V7.2.0 and above

Workspace 89 × 150 × 150mm (including 75mm head riser)

2. Key optional accessories

Value of specific options for accessory categories

Upgraded electric XY stage (150mm stroke) and coded XYZ stage to support automated measurement and improve positioning repeatability

Objective lens and turntable with 4-digit electrically encoded objective lens turntable, long/ultra long working distance objective lens, and glass compensation objective lens adapted to complex samples, achieving automatic switching of objectives

Expansion of workspace by 35mm/176mm Gantry riser kit to extend working height to 265mm, suitable for thick samples and deep cavity parts

Calibration and fixture calibration standard parts (0.088 μ m/1.8 μ m/25 μ m step, 30/50mm SiC reference plane), 150mm vacuum sample fixture ensure measurement accuracy, fix irregular samples

Workstation supporting side desk (including monitor stand, drawer, cable management) optimizes operating space and improves equipment placement cleanliness

Typical application scenarios

NewView 9000, with its "wide adaptability+high precision", covers core applications in multiple fields. The typical scenarios mentioned in the manual are as follows:

Characterization of MEMS devices: measuring the height, spacing, and roughness of microstructures (such as cantilever beams and grooves) to verify process consistency;

Optical component testing: Analyze the surface shape errors (such as PV, RMS) and surface textures of lenses and mirrors to ensure imaging quality;

Precision mechanical parts: detect the turning texture of diamond turned parts (such as nickel mirrors), the microstructure of gear edges, and evaluate machining accuracy;

Transparent film analysis: optional "thick film analysis module", measuring the thickness and refractive index distribution of transparent films above 400nm;

Biological and Medical Devices: Characterize the surface texture of prostheses, microfluidic chip channel morphology, optimize biocompatibility and fluid performance.

Core Summary and Applicable Users

1. Core value of equipment

NewView 9000 is an all-in-one tool for high-precision surface measurement, and its core value lies in:

Technically: Integrating CSI and SureScan ™ Balancing "precision, speed, and anti-interference ability" with patented technology;

Hardware wise: Open architecture+flexible accessories, adapted to measurement needs ranging from "small-sized chips" to "large-sized parts";

Software wise: Mx ™ The platform lowers the operational threshold while providing professional analysis functions, catering to both novice and expert users.

2. Suitable for users

Research institutions: Micro nano manufacturing, materials science, MEMS fields in universities and research institutes, used for basic research and process development;

Industrial sector: semiconductor, optical manufacturing, precision machinery industry, used for production line quality inspection and high-end component acceptance;

Testing laboratory: a third-party metrology institution used for high-precision surface parameter calibration and arbitration measurement.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands