Zygo NewView 9000 3D Optical Profilometer Technology Advantages

Zygo NewView 9000 3D Optical Profilometer Technology Advantages

Equipment core positioning and technological advantages

1. Core positioning

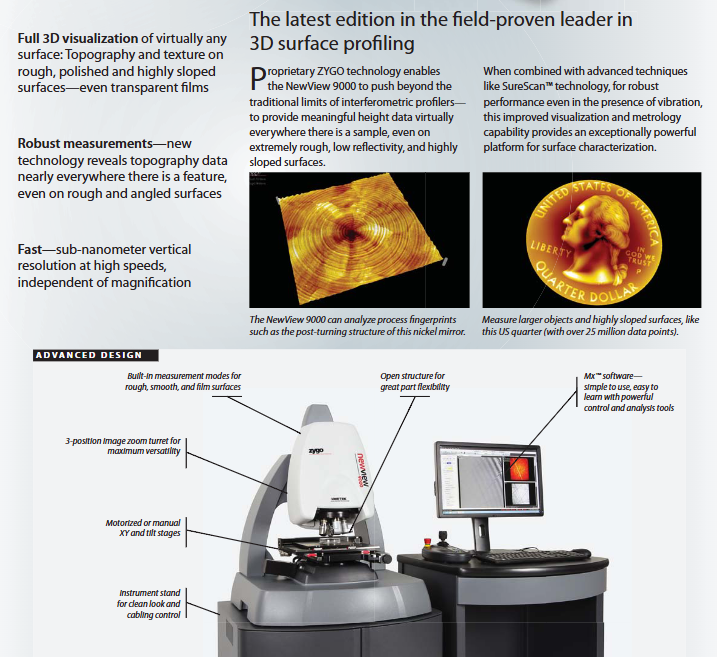

NewView 9000 is a high-end desktop 3D surface profilometer launched by Zygo, which adopts non-contact measurement technology and is designed for "high-precision, wide adaptability, and high robustness" surface characterization. It can cover the full scene measurement requirements from "atomic level smooth surfaces" to "rough microstructure surfaces". Typical applications include surface morphology, texture, and step height analysis of MEMS devices, optical components, precision mechanical parts, etc.

2. Four core technological advantages

The specific manifestation value of technological advantages

Full scene surface adaptation supports 3D visualization of rough, polished, high slope surfaces, and even transparent films;

Samples with low reflectivity (≥ 0.05%) and high slope (smooth surface ≤ 55 °, scattering surface ≤ 85 °) can be measured without sample pretreatment, covering over 90% of micro nano surface measurement requirements

Strong measurement robustness equipped with Zygo patented technology (such as SureScan) ™), Can still maintain accuracy in vibration environments (1-120Hz);

Data collection without blind spots - even if there are complex features on the surface (such as grooves and sharp corners), effective height data can still be generated to adapt to non ideal environments such as workshops and multi device laboratories, reducing measurement failure rates

Balancing high precision and high speed with vertical resolution: sub angstrom level (RMS repeatability 0.008nm), and independent of magnification;

Acquisition speed: Complete full field of view measurement within 1 second in Smart PSI mode, balancing "nanometer level accuracy" and "batch measurement efficiency", suitable for scientific research and industrial quality inspection

High operational convenience, open structure design, convenient sample loading and observation;

The software adopts a "workflow oriented" logic, which can complete complex analysis without professional programming skills, reduce operational barriers, and shorten personnel training cycles

Hardware configuration and performance indicators

1. Core hardware components

(1) Optical system

Specific configuration characteristics of components

Measurement technology: 3D coherent scanning interferometry (CSI)+Smart PSI technology (sub angstrom accuracy)+SureScan ™ Technology (anti vibration) multi technology integration, balancing accuracy, speed, and anti-interference ability

The most comprehensive selection of objective lenses in the objective lens system industry, covering 1 × -100 × magnification and supporting 4 types of objective lens:

1. Standard working distance (e.g. 100 × NA=0.85, optimal optical resolution);

2. Long working distance (LWD, such as 1 x working distance of 8mm);

3. Extra long working distance (SLWD, such as 1 ×/5 × working distance of 40mm);

4. Glass compensation (GC, suitable for samples with transparent windows) adapts to different sample thicknesses and loading methods, such as SLWD objective for thick samples and GC objective for samples with protective windows

Optical zoom comes standard with a 3-digit electric coding zoom turntable (including a 1.0 x zoom tube), with optional 0.5 x/0.75 x/1.5 x/2.0 x zoom components and objective lenses to expand the field of view (0.04 x 0.04mm-17.49 x 17.49mm). The coding design ensures repeatability of zoom positions

Lighting system with white LED light source, equipped with manual field stop, aperture stop, and spectral filter to adapt to different reflectivity samples, adjust lighting intensity and spectrum, and improve data signal-to-noise ratio

(2) Motion and stage system

Stage type XY axis stroke tilt range (Tilt) Core advantages

Manual stage 100mm ± 4 °, low cost, suitable for fixed position measurement

Electric stage (optional) 150mm ± 4 ° supports automated stitching (field of view stitching) and patterned sampling;

Optional "Encoding XYZ" configuration for higher repeatability in positioning

Workplace standard: 89 × 150 × 150mm;

Optional 176mm riser kit: 265 × 150 × 150mm supports large-sized samples (such as 89mm high samples), and the riser kit is suitable for measuring deep cavities and thick samples

(3) Structural and environmental adaptation

Physical dimensions: desktop host 75 × 64 × 56cm, with bracket 151 × 73 × 61cm;

Weight: desktop 91kg, with bracket 229kg;

Vibration isolation: comes standard with a vibration isolation system that meets VC-C level vibration standards (1-120Hz);

Environmental requirements: temperature 15-30 ℃ (rate of change<1 ℃/15min), humidity 5% -95%, no condensation.

2. Key performance indicators (laboratory conditions)

Performance category indicator notes

Surface morphology repeatability at 0.08nm full magnification, suitable for Smart PSI mode+3 × 3 median filtering

RMS roughness repeatability of 0.008nm, also known as' vertical resolution ', reflects the accuracy of surface detail measurement

Field of view range 0.04 × 0.04mm (100 × objective lens+2 × zoom)~17.49 × 17.49mm (1 × objective lens+0.5 × zoom) supports field of view stitching, expanding to a larger measurement area

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands