Zygo NewView 9000 3D Optical Profilometer Technology

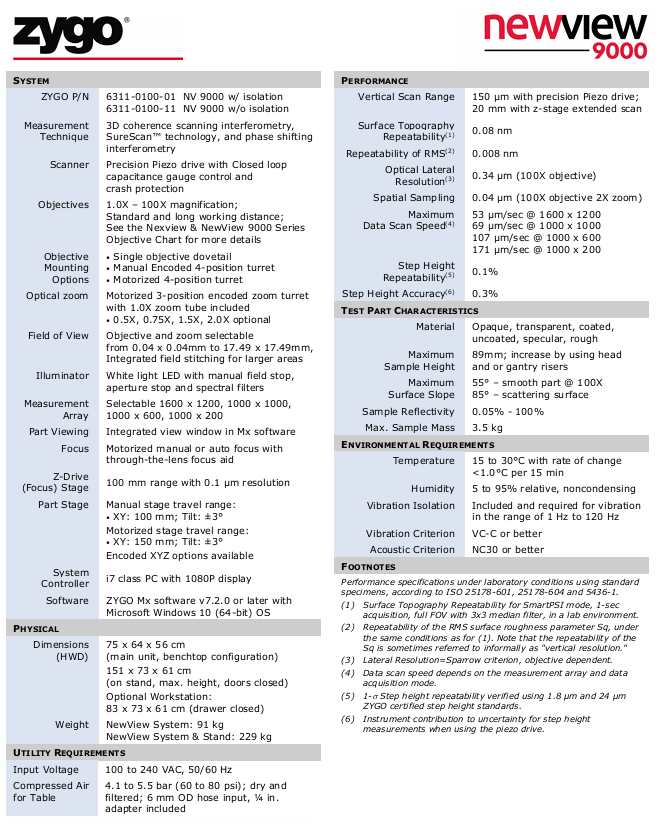

Optical lateral resolution (3) 0.34 μ m (100X objective) Based on the Sparrow criterion, the higher the objective magnification, the higher the lateral resolution

Data scanning speed (4) 171 μ m/s (1000 × 200 array) The speed varies with the "measurement array size" and "acquisition mode", and the small array is suitable for high-speed measurement

Step height repeatability (5) 0.1% (1 σ) verified with Zygo certified step standard parts at 1.8 μ m and 24 μ m

Step height accuracy (6) 0.3% with instrument contribution only uncertainty, based on piezoelectric drive measurement

Sample adaptation range

NewView 9000 supports multiple types of samples and adapts parameters covering key dimensions such as material, size, and surface characteristics

Description of sample characteristic adaptation parameters

Material: opaque (metal, silicon wafer), transparent (glass, polymer), coated/uncoated, smooth/rough surface. White LED and filter are compatible with low reflectivity samples (minimum reflectivity of 0.05%)

The maximum height of the sample is 89mm; it can be expanded through the "lens holder/gantry risers". Attention should be paid to the working distance of the objective lens to avoid collision between the sample and the objective lens

Smooth surface slope: maximum 55 ° (100X objective lens);

Scattering surface: Suitable objective lens should be selected for high slope samples with a maximum angle of 85 ° to avoid data loss

The maximum sample weight is 3.5kg to protect the accuracy of the stage movement. For overweight samples, customized load-bearing components are required

Environmental requirements

To ensure measurement accuracy, the following environmental conditions must be met, with core control of "temperature, vibration, acoustics" interference:

Purpose of environmental category requirements

Temperature 15-30 ° C; temperature change rate<1.0 ° C/15 minutes to avoid material thermal deformation affecting the optical system and sample

Humidity 5% -95% relative humidity, non condensing to prevent condensation of optical components and rusting of metal parts

Vibration isolation comes standard with a vibration isolation system (model 6311-0100-01);

Vibration range: 1Hz-120Hz;

Vibration standard: It is required to meet the requirement that vibration of VC-C level or above will cause interference fringes to blur, affecting the accuracy of height data

Acoustic environment NC30 level or above (noise ≤ 30 decibels) to avoid the transmission of sound wave vibrations to equipment and interference with precision moving components

Core notes and applicable scenarios

Timeliness of specifications: Technical parameters may change without prior notice, and actual configuration should be based on the latest official Zygo documentation;

Applicable scenarios:

Research field: Surface roughness of MEMS devices, microstructure step height, and surface morphology analysis of biomaterials;

Industrial field: semiconductor wafer flatness, optical component surface shape error, precision mold surface quality inspection;

Calibration requirements: Zygo certified standard parts (such as step height standard parts, reference planes) need to be calibrated regularly to ensure stable performance indicators.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands