SCHNEIDER PowerPact ™ H. Modbus Communication User Guide for J and L-type Circuit Breakers

SCHNEIDER PowerPact ™ H. Modbus Communication User Guide for J and L-type Circuit Breakers

Overview of Document Core

(1) Document positioning and scope of application

This guide is PowerPact ™ H. The comprehensive technical manual for Modbus communication of J and L-type circuit breakers is suitable for equipment installation personnel, maintenance personnel, and technical operators. Its core purpose is to provide full process guidance for the installation configuration, communication operation, data acquisition, remote control, and other aspects of Modbus protocol applications for this series of circuit breakers. The applicable equipment must meet specific firmware version requirements, such as MicroLogic 5 and 6 trip unit firmware ≥ V001.003.00 in IMU module, IFE Ethernet interface firmware ≥ V004.007.00, etc. Its core value lies in achieving remote monitoring and control of circuit breakers, including reading measurement data, diagnostic information, status conditions, remote operation of circuit breaker opening and closing, configuration of protection parameters, synchronization of date and time, etc. All operations must be carried out by qualified electrical personnel and strictly comply with password management and permission control requirements to ensure operational safety.

(2) Compliance and Safety Standards

International standards: Follow international electrical standards such as IEC/EN 60947-4-1, UL 508, CSA C22.2 No.14, etc.

Network security: The default password must be changed for the first use, and unused ports, services, and default accounts must be disabled; Networking devices require the deployment of multiple layers of network defense, such as firewalls and network segmentation; Adopting network security best practices such as minimum privilege and separation of responsibilities to prevent illegal access, data leakage, or service interruption.

Related documents: Need to be used in conjunction with PowerPact circuit breaker user guide, MicroLogic trip unit user guide, ULP system user guide and other related documents. The latest version can be downloaded from Schneider Electric's official website.

Detailed explanation of communication interface

(1) IFM interface (Modbus SL)

Core parameters

Part number: LV434000 (completely replacing TRV0021/STRV00210), compatible with MasterPact MTZ circuit breaker, while the old part number TRV0021/STRV00210 is not compatible with this model of circuit breaker.

Communication interface: equipped with RJ45 Modbus SL port and optional stacking interface (TRV00217), supporting multi interface expansion connection.

Address setting: The address is defined through the two rotary switches on the front panel, ranging from 1-99. The default address is 99, and address 0 is reserved for broadcasting and cannot be used for setting individual device addresses.

Power requirements: A 24Vdc power supply is required, and it is recommended to use UL certified/approved limited voltage/limited current level 2 power supply (maximum 3A). Only copper wires are allowed for wiring.

Padlock function: The arrow points to enable remote control commands when opening the padlock (factory settings); Disabled when pointing to the closed padlock, only the 'Set absolute time and get current time' command is not restricted.

Configuration method: default automatic configuration, can automatically detect baud rate (4800/9600/19200/38400) and parity; Network parameters can also be manually configured through the EcoStruxure Power Commission software.

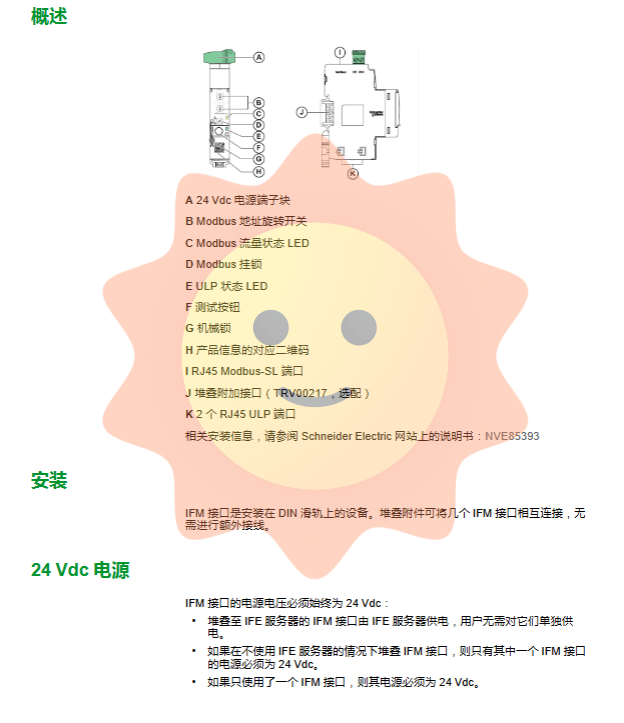

Hardware Description and Installation

Hardware composition: including 24Vdc power terminal block, Modbus address rotary switch, Modbus flow status LED, Modbus padlock, ULP status LED, test button, mechanical lock, QR code (product information), RJ45 Modbus SL port, stacked additional interface, 2 RJ45 ULP ports.

Installation method: Installed on a DIN rail, stacking accessories can connect multiple IFM interfaces to each other without additional wiring. The IFM interface stacked on the IFE server is powered by the IFE server; When there is no IFE server, stacked IFM interfaces only require one power supply, and a single IFM interface needs to be powered separately.

Circuit diagram and connection specifications

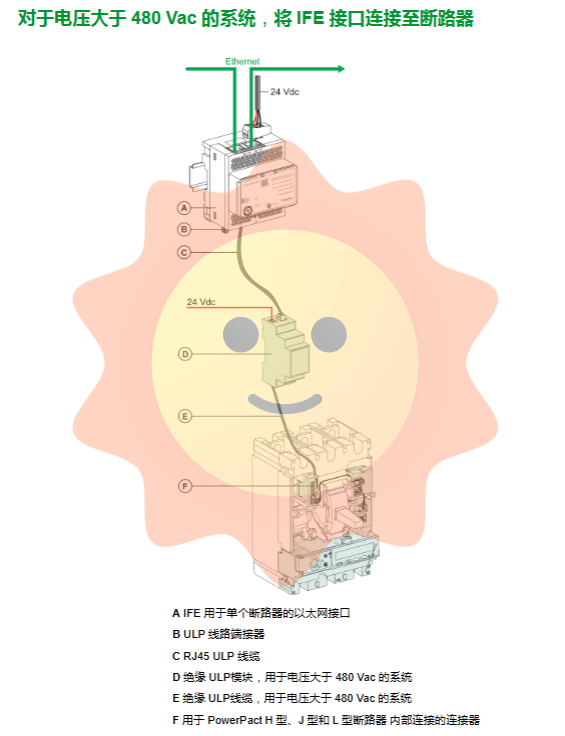

Connection configuration: Depending on the type of circuit breaker, it can be connected to MicroLogic trip units, BSCM modules, or both simultaneously; Insulated NSX cables are required for systems with voltages greater than 480 Vac.

Port protection: The RJ45 port of the IFM interface is only suitable for ULP modules. The unused second ULP RJ45 connector needs to be sealed with a ULP line terminator to avoid equipment damage.

(2) IFE interface (Ethernet)

Core parameters

Type and Part Number: Divided into single circuit breaker Ethernet interface (LV434001/LV434010) and Ethernet server (LV434002/LV434011), LV434001 replaces LV434010, LV434002 replaces LV434011, the new part number has real-time clock (RTC) function, and the ULP connection distance with MasterPact MTZ circuit breaker can reach 20 meters, while the maximum connection distance with the old part number is 5 meters.

Communication interface: Dual RJ45 communication ports, supporting daisy chain connection, but embedded switches do not support ring topology (without loopback protection).

IP configuration: Default DHCP mode, press the reset button for 1-5 seconds to restore the default IP configuration.

Power requirements: A 24Vdc power supply is required, and it is recommended to use a UL labeled and approved limited voltage/current level 2 power supply (maximum 3A), with only copper wires used for wiring; The IFM interface stacked on the IFE server is powered by the IFE server and does not require separate power supply.

Padlock function: Consistent with the IFM interface, the arrow points to open the padlock to enable remote control commands, and close it to disable it. Only the "Set Absolute Time" command is not restricted.

Features: Supports device configuration file network services (discovering IFE interfaces within the local area network), ULP compatibility (adapting to installation and positioning in distribution panels), embedded settings/monitoring/control web pages, server functionality for Modbus SL connected devices (limited to LV434002), email alarm notifications.

Hardware Description and Installation

Hardware composition: Includes dual RJ45 communication ports, 24Vdc power terminal block, QR code (product information), Ethernet communication LED, module status LED, network status LED, sealable transparent cover, reset button, ULP status LED, test button, padlock, Modbus traffic status LED (IFE server only), device name label, two RJ45 ULP ports, grounding connection.

Installation method: Installed on a DIN rail, LV434002 IFE server can be connected to multiple IFM interfaces through stacked accessories without additional wiring.

Indicator light status description

Ethernet communication LED: Dual color LED indicates the status of ETH1 and ETH2 ports, off indicates no power or no link; The constant yellow light indicates the establishment of a 10 Mbps link but no activity, while the flashing yellow light indicates the 10 Mbps active state; A constant green light indicates that a 100 Mbps link has been established but there is no activity, while a flashing green light indicates a 100 Mbps active state.

Module status LED: The dual color LED indicates the status of the IFE interface, and off indicates that it is not powered on; A constant green light indicates normal operation; Green light flashing (250ms on/off) indicates that the hidden control webpage is available; Green light flashing (500ms on/off) indicates firmware damage; Red light flashing (500ms on/off) is in degraded mode; If the red light is constantly on, it means it has stopped running; Green/red flashing alternately (switching for 1 second) indicates firmware update in progress; The rapid alternating flashing of green/red light (250ms switching) indicates self checking.

Network status LED: Dual color LED indicates network status, off indicates no power or no IP address; A green light that stays on is a valid IP address; A constant red light indicates a duplicate IP address; Alternating flashing of green/red light (250ms switching) indicates self-test; An amber constant light indicates an IP configuration error.

Modbus Traffic Status LED: Only available on IFE servers. A yellow LED indicates that data is being transmitted or received through the Modbus serial line network. If it is turned off, there will be no data transmission.

Deep Analysis of Modbus Protocol

(1) Basic Principles of Communication

Master slave mode: Adopting a one master multiple slave mode, one master device (monitor/PLC) can connect up to 31 slave devices (circuit breakers), and only one master device can connect to the network at a time.

Communication process: Only the master device can initiate communication and send requests. It can access a single slave device through a separate address or broadcast access to all slave devices using address 0; The slave device can only respond to requests from the master device and cannot initiate communication or communicate with other slave devices.

Response time: The typical response time is less than 10ms, with a maximum value of about 700ms. It is recommended to have an interval of ≥ 1 second between two Modbus requests to avoid communication conflicts.

Data type: Supports register (16 bit) data type, does not support single bit type; The relationship between register number and address is "address=register number -1", for example, the address of register number 12000 is 0x2EDF (11999).

Frame structure: Each Modbus frame has a maximum of 256 bytes and contains 4 fields - slave device number (1 byte, 0 for broadcast, 1-247 for independent addresses), function code (1-2 bytes), data (n registers, n maximum of 52, with MasterPact MicroLogic E trip unit), CRC16 checksum (2 bytes, detecting transmission errors).

(2) Core functional code

Function code, sub function code name, usage restriction explanation

0x03- Read hold register Read output/Internal registers (such as measurement values, device status) Read up to 52 registers

0x04- Read Input Register Read Input Register (such as sensor data) Read up to 52 registers

0x2B 0x0E Read device identification Read identification data from the device-

0x2B 0x0F Get date and time Read date and time from device supports broadcast synchronization of all slave device times

0x2B 0x10 Set date and time Write date and time from device, supports broadcast mode batch setting

0x06- Preset a register to write a single parameter (such as protection threshold)-

0x10- Preset multiple register batch write parameters (such as multiple protection settings) to write up to 52 registers

0x08- Diagnostic Management Diagnostic Counter-

0x08 0x0A Clear counters and diagnostic registers Reset all diagnostic counters-

0x08 0x0B Return Bus Message Counter Read Correct Bus Message Counter-

0x08 0x0C Return Bus Communication Error Counter Read Error Bus Message Counter-

0x64 0x04 Read Distributed Hold Register Read Non Continuous Register n Maximum 100, When equipped with MasterPact MicroLogic A/E trip unit, it is recommended that n ≤ 21

(3) Exception code and handling

Common reasons and handling methods for the meaning of exception code names

0x01 Illegal function request function code is not authorized by the device. Check if the function code is supported and confirm if the device status is normal

0x02 Illegal Data Address Request: The data address requested is not authorized by the device. Confirm if the register address exists and check if the firmware version of the device supports this register. When upgrading the firmware, use EcoStruxure Power Commission software to operate

0x03 Illegal Data Value Request: The value in the data column is not authorized by the device. Check if the written parameter exceeds the allowed range and verify the parameter configuration requirements

0x04 Device failure encountered an irreparable error while executing a request operation from the device. Restart the device, check its hardware status, and contact technical support if necessary

0x05 confirms receipt of request from device but requires a long processing time before resending request to avoid repeated triggering

0x06 Busy slave device. The slave device is processing other commands and waiting for the slave device to become idle before sending requests. Optimize the request sending interval

0x07 Negative confirmation: The device is unable to execute programming requests. Check the legality of programming parameters and confirm whether the device is in a programmable state

0x08 Memory Parity Error Detected parity error while reading expansion memory from device. Check device memory status and repair or replace device if necessary

0x0A gateway channel unavailable. Gateway overload or configuration error. Check gateway load and optimize gateway configuration

0x0B gateway target device failed to respond to the request from a slave device that does not exist in the network. Confirm the slave device address configuration and check the device network connection

Dataset and Register Configuration

(1) Dataset classification and selection

Standard dataset (32000-32341)

Core content: Includes high-precision data such as circuit breaker status, tripping reasons, real-time measurement values (current, voltage, power, energy), harmonic distortion, etc., covering the core requirements of distribution monitoring.

Advantages: Fast response speed, complete data can be obtained through 3 Modbus read requests; The data format has high precision and supports data types such as INT64 and FLOAT32, meeting high-precision measurement requirements.

Applicable scenarios: New applications, scenarios that require data accuracy and response speed, compatible with IFM interfaces, IFE interfaces, and IFE servers.

Old dataset (12000-12165)

Core content: Compatible with older devices, including basic measurement values and device status data, consistent with the core monitoring content of the standard dataset, but with weaker support for data accuracy and format.

Advantage: A single request can read 114 registers, compatible with old circuit breakers and monitoring systems.

Applicable scenarios: Upgrades and renovations of old devices that require compatibility with existing Modbus monitoring systems are not recommended for new applications.

(2) Core module register details

① MicroLogic trip unit register

Real time measurement (1000-1146): refreshed per second, including voltage (phase to phase voltage, phase voltage, voltage imbalance), current (phase current, neutral line current, current imbalance), power (active, reactive, apparent, distorted power), power factor, frequency, total harmonic distortion (THD) and other data, supporting multi-dimensional electrical parameter monitoring.

Electricity measurement (2000-2031): Write non-volatile memory every hour, including active energy, reactive energy, apparent energy, forward/reverse energy, etc. It supports energy accumulation and statistics and can be reset through a reset command (command code 46728) (excluding accumulated energy).

Demand measurement (2200-2237): The duration of the current demand window can be configured, and the power demand supports block/sliding windows. The sliding window demand value is updated every minute, and the block window demand value is updated at the end of the window period, including phase current demand, total active/reactive/apparent power demand, and peak demand.

Protection parameters (8754-8930): covering protection parameters such as long delay, short delay, instantaneous, ground fault, locked rotor, imbalance, underload, long start, neutral line, etc., supporting the configuration of key parameters such as protection threshold and delay time through dedicated commands.

Log Register (5732-29549): Contains 10 alarm logs, 17 trip logs, and 10 maintenance operation logs, each with a timestamp (ULP DATE format), supporting fault tracing and maintenance record queries.

② BSCM module register

Identification register (551-557): Product identification (15149 corresponds to BSCM module), serial number (PPYYWWDnnn format), supports module identity recognition and traceability.

Status registers (563-564): Circuit breaker status (OF input, SD input, SDE input status), communication electric mechanism status (electric mechanism availability, manual/automatic mode, previous command execution status, etc.), real-time monitoring of circuit breaker operation status.

Maintenance indicator (571-582): includes 7 counters including cumulative OF counter (non resettable), OF counter, SD counter, SDE counter, and on/off command counter. It supports setting a threshold (default 5000) and generates an alarm when the counter reaches the threshold to assist in the development of maintenance plans.

Event log (602-652): 10 event records, including event identification, date and time, event status, supporting event tracing, event identification covering SD contact changes, threshold triggering, internal faults, and other scenarios.

③ IO module register

Analog input (13824-13929/16824-16929): Supports Pt100 temperature sensor input, measurement range -50~250 ℃, updated once per second, including data quality identification (valid/invalid) and data change timestamp.

Digital input/output (13930-14000/16930-17000): 6 digital inputs, 3 digital outputs, supporting status monitoring and control. The digital input status includes an "on/off" indicator, and the digital output supports remote control.

Alarm status (203-205): User defined alarm (201-210) activation status, supports custom alarm thresholds and triggering conditions, and the corresponding bit identifier when the alarm is activated is 1.

Hardware settings (197-198): including module hardware configuration parameters, supporting the adaptation configuration of IO modules and circuit breakers.

Remote Command and Control Process

(1) Command execution general process

Load command parameters into the buffer (registers 8000-8015), specifying the command code, parameter length, destination, security type, password, and additional parameters.

Send command requests through Modbus function code 0x10 (write multiple registers) to ensure that the parameter format is consistent with the register requirements.

Read the command status register 8021. If the content is 0x0003, it indicates that the command is being executed and needs to wait continuously.

Read the command code register 8020 and confirm that it matches the command code input in step 2. If it does not match, execute the process again.

Read the error code of the least significant bit of register 8021, where 0 indicates successful execution and non-zero indicates troubleshooting based on the error code (such as password errors, insufficient permissions, etc.).

(2) Example of Key Commands

Circuit breaker opening (command code 904)

Permission requirement: Administrator/operator level password.

Execution steps: ① The padlock is in the open state; ② Write command code 904 to register 8000, with a parameter length of 10 bytes, destination 4353 (0x1101), security type 1, and enter the administrator/operator password; ③ Confirm the command execution status according to the general process; ④ Verify the status register of the circuit breaker (32001) and confirm successful disconnection.

Protection parameter configuration (taking long delay protection as an example, command code 45192)

Permission requirement: Administrator level password.

Execution steps: ① Write command code 45192 to register 8000, with a parameter length of 18 bytes and destination 5121 (0x1401); ② Configure parameters such as Ir setting value (determined by the rated current In of the transformer), TR delay (500-16000ms for distribution applications), motor category (5-30 seconds for motor applications), etc; ③ Execute and verify the configuration results according to the general process, and read the configured parameters through registers 8754-8763.

Data synchronization command (set date and time, function code 0x2B, sub function 0x10)

Permission requirement: No password protection, can still be executed when the padlock is closed.

Execution steps: ① The main device sends a command containing the target date and time (year, month, day, hour, minute, second, millisecond); ② Support broadcast mode (from device address 0) to synchronize all slave device times; ③ After a power outage, devices without batteries need to resynchronize their time. It is recommended to synchronize every 15 minutes to offset clock drift.

(3) Permission and Security Control

User permission classification: divided into four levels: Administrator (highest permission), Services, Engineer, and Operator. Different commands require corresponding permission passwords, such as protecting parameter configuration requires administrator passwords, and opening and closing commands require administrator/operator passwords.

Password rules: The default passwords are 0000 (Administrator), 1111 (Services), 2222 (Engineer), 3333 (Operator), and must be modified for the first use; The password is composed of 4 ASCII characters, case sensitive, and supports both numbers and letters.

Double protection: Hardware padlock (IFM/IFE interface)+software password. Most remote control commands are disabled when the padlock is closed, except for time synchronization commands; Hardware protection takes priority over software protection.

Safety and Maintenance Standards

(1) Operational safety requirements

Personnel qualifications: Installation, maintenance, and operation must be carried out by qualified electrical personnel who possess knowledge of electrical equipment installation, operation, and safety, and have undergone professional safety training.

Electrical safety: Wiring must comply with voltage level requirements, and insulated cables are required for systems with voltages greater than 480 Vac; The power supply should use UL certified Level 2 power supply to avoid equipment damage caused by overload or power failure.

Network security: Disable unused ports, services, and default accounts; Regularly change passwords to avoid password leakage; Deploy firewalls and network segmentation to prevent malicious network attacks.

(2) Maintain management standards

Firmware update: Use EcoStruxure Power Commission software to update the IMU module firmware, ensuring compatibility between registers and command functions, and avoiding functional unavailability due to low firmware versions.

Log audit: Regularly review alarm logs, trip logs, maintenance operation logs, trace the cause of faults and equipment operation status, and assist in developing maintenance plans.

Maintenance indicator: Read maintenance parameters such as circuit breaker usage time, contact wear rate, and opening and closing times through registers, and perform maintenance or component replacement in a timely manner when the counter reaches the threshold.

Password management: When forgetting the administrator password, it is necessary to reset it to the default password through EcoStruxure Power Commission software combined with Schneider Electric customer service center support.

Common Problems and Solutions

Problem 1: Automatic configuration of IFM interface failed, unable to establish Modbus communication

Solution:

Confirm that the Modbus master device sends at least one Modbus frame within 25 seconds, and the automatic detection algorithm needs to be triggered by the master device request.

Set the IFM interface address to 1, and the master device sends multiple register read requests with function code 0x03 to address 1 at least 25 times.

If it still fails, switch to manual configuration and set the baud rate and parity through EcoStruxure Power Commission software.

Check the power wiring (24Vdc) and copper wire usage requirements to ensure stable power supply.

Problem 2: Remote opening and closing command execution failed, returning error code 2 (access violation)

Solution:

Check the status of the IFM/IFE interface padlock, ensure that the arrow points to open the padlock, and enable remote control commands.

Confirm that the entered password corresponds to the administrator or operator permissions. Incorrect password will result in permission verification failure, and the correct permission password must be entered.

Check the status of the circuit breaker. If the circuit breaker has tripped, reset it first and then execute the opening and closing command.

Problem 3: Abnormal data parsing results when reading electrical energy data

Solution:

Confirm the dataset selection, the standard dataset energy register is 32096-32099 (INT64 type), and the old dataset is 12050-12051 (INT32 type) to avoid address errors.

Parse data in Big Endian format, INT64 type requires combining 4 register data, INT32 type requires combining 2 register data.

Check the validity of the data. The "Data Availability" bit of the standard dataset register 32000 or the old dataset register 12000 should be 0 (valid). If it is 1, the data is invalid.

Confirm that the firmware version supports this register. The old firmware may not have implemented some high-precision energy registers and requires firmware upgrade.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands