Yokogawa ROTOMETER RAMC Metal Variable Area Flow Meter

The flow indication deviation is large, and the viscosity/density of the fluid does not match the calibration value. The wear of the float provides new fluid parameters, and the manufacturer recalculates the scale; Replace the worn float

Improper threshold setting for triggering limit switch misoperation, recalibration of switch threshold due to magnetic field interference (such as 5% Qmax), and staying away from strong magnetic field sources

Application of Safety Instrumented System (SIS)

1. Applicable models and safety functions

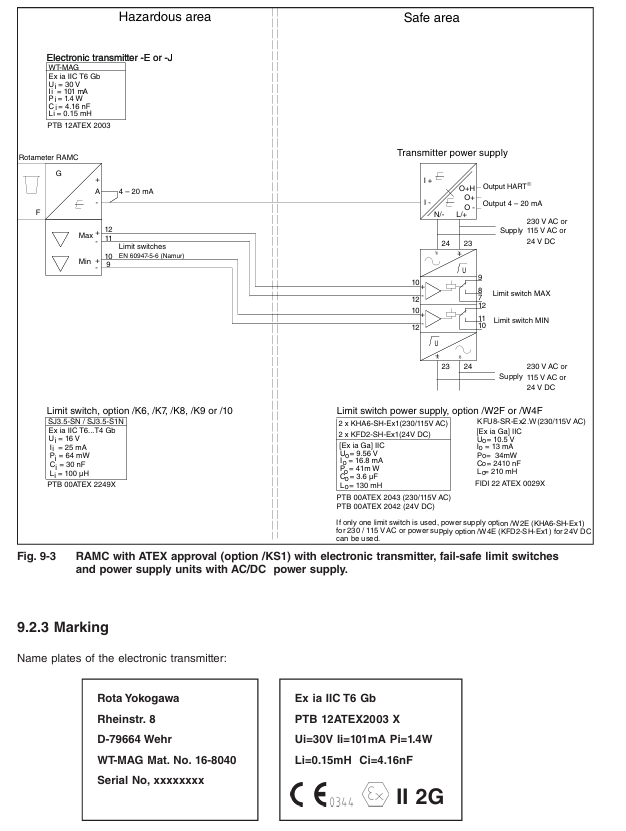

RAMC only comes with fail safe limit switches (V1) and standard limit switches (V2), which can be used for SIS as flow monitoring components connected to safety instrument functions (SIF). The core realizes "flow over limit alarm" or "emergency cut-off trigger", and supports SIL1-SIL2 levels (depending on configuration and verification cycle).

2. Key SIS requirements

Verification cycle: It should be set according to safety integrity requirements, with a recommended duration of 1-5 years. The verification coverage rate should be ≥ 99%, and the verification results should be recorded (such as forcing the float to trigger the MAX/MIN threshold and verifying the switch action);

Reliability data: V1 type (fail safe switch) SFF=61%, MTBF=530 years, V2 type (standard switch) SFF=42%, MTBF=401 years. Detailed FMEDA reports can be obtained from the manufacturer;

Lifecycle: Designed for a lifespan of 10 years, if exceeded, reliability needs to be reassessed or core components such as measuring tubes and floats need to be replaced.

Compliance and Disposal Standards

1. Compliance with PED Pressure Equipment Directive

RAMC complies with 2014/68/EU (PED), the measuring tube is classified as "pipeline", the heating element (/T1-/T6 options) is classified as "container", fluid group 1-2, module H, and some models (such as RAMC03-15) belong to Class III pressure equipment and need to comply with pressure temperature ratings (such as stainless steel material -196 ° C~370 ° C, PTFE material -80 ° C~130 ° C).

2. Requirements for abandonment and return to factory

Decontamination treatment: After coming into contact with harmful fluids, the equipment should be thoroughly cleaned to avoid residual corrosion or toxicity. A "Decontamination Declaration" should be submitted when returning to the factory;

Environmental disposal: It belongs to WEEE equipment (2012/19/EC) and is prohibited from being mixed with municipal waste. It must be collected by professional institutions or returned to designated outlets in Yokogawa for disposal.

Summary and selection suggestions

1. Core advantages

Wide applicability scenarios: Supports corrosive, opaque, turbulent fluids, temperature range -196 ° C~370 ° C, pressure range PN16~PN100;

Flexible function expansion: optional electronic transmitter (HART communication), limit switch (fail safe), explosion-proof certification (global major system);

Low maintenance cost: The measuring tube and float are made of durable materials (such as 316L stainless steel), with no vulnerable parts. Calibration only requires replacing the EEPROM and scale.

2. Key parameters for selection

Fluid characteristics: Select the material of the measuring tube/float based on density, viscosity, and corrosiveness (such as PTFE for strong corrosion and stainless steel for conventional fluids);

Explosion proof requirements: Hazardous areas require matching certification types (such as China Select/NS1, US Canada Select/FS1);

Signal output: Remote monitoring should select the - J type (HART), only local indication should select the - T type, and alarm control should be equipped with/K series limit switches.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands