Yokogawa ROTOMETER RAMC Metal Variable Area Flow Meter

Damping setting (F21): Smooth output signal for 0/1/5/10 seconds to reduce the impact of flow fluctuations, with a default of 1 second

Current output (F3-) 4-20mA/0-20mA switch 2-wire system default 4-20mA, adjustable zero point (F32) and range (F33), 20 μ A per step

Fault detection (F4-) error code displayed as "08" indicates that the float is stuck and needs to be cleaned or automatically zeroed (F74)

Float stuck detection (F7-) on/off, monitoring lower limit (5%/15%/30% Qmax), monitoring time 5/15 minutes optional. If there is no signal fluctuation beyond the deadline, a fault alarm will be triggered

(2) HART 7 communication (- J type exclusive)

Communication features: Supports 2-wire 4-20mA overlay with HART signal, enables remote parameter configuration and data reading (such as real-time flow, cumulative value, diagnostic information), supports multi slave mode (up to 63 devices), and can set polling address 1-63.

Core functions:

Process variable monitoring: real-time reading of flow rate, temperature, current output, etc;

Fault diagnosis: detect RAM errors, ADC faults, EEPROM anomalies, etc;

Burst mode: Continuously sending specified data (such as traffic+cumulative value) to reduce communication latency;

Trend configuration: Record 12 sets of historical data, with adjustable sampling intervals of 1-2 hours.

2. Limit switch (/K1-/K10 options)

Type and Function:

Standard type (/K1-/K3): Supports MAX/MIN dual contacts and complies with EN 60947-5-6 (NAMUR) standard;

Fault safe type (/K6-/K10): When power is cut off, the contacts automatically switch to a safe state and require a dedicated power supply (such as/K2E,/W4F).

Parameter configuration: Set the MIN-MAX/MIN-MIN/MAX-MAX function by switching the direction of the power supply. For example, when the K3 option is paired with the W2B power supply, the S1/S2 relay position determines the contact logic.

Explosion proof certification and safety regulations

1. Explosion proof type and applicable scenarios

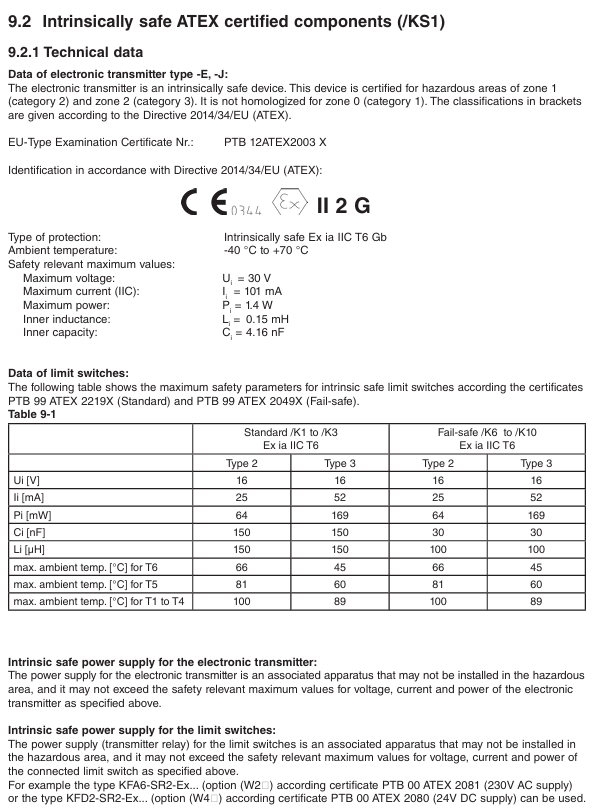

RAMC provides two types of explosion-proof designs: intrinsic safety (Ex ia) and explosion-proof (Ex db), covering major certification systems worldwide. The core parameters are as follows:

Certification Type Model Options Explosion proof Mark Applicable Area Key Parameters (Electronic Transmitter)

ATEX/KS1 (intrinsic safety) Ex ia IIC T6 Gb Zone 1/2 (gas), Zone 21/22 (dust) Ui=30V, Ii=101mA, Pi=1.4W

IECEx/ES1 (Intrinsic Safety) Ex ia IIC T6 Gb Global Explosion proof Zone Li=0.15mH, Ci=4.16nF

NEPSI (China)/NS1 (Intrinsic Safety) Ex ia IIC T6 Gb Explosion proof Area Environmental Temperature in China -40 ° C~+70 ° C

FM/UL (US Canada)/FS1 (Intrinsic Safety) Class I Div1 GP A-D T6 US Canada Zone 1/Zone 2 Vi=30V, Ii=100mA, Pi=1.4W

EAC (Eurasian Economic Union)/GS1 (Explosion proof+Dust) Ex db IIC T6 Gb/Ex tb IIIC T80 ° C Db Eurasian Union Explosion proof Area Surface Temperature ≤ 80 ° C (T6)

2. Explosion proof installation and operation taboos

Intrinsic safety requirements:

The power supply must be a certified associated device (such as KFA6-SR2-Ex2. W) installed in a safe area;

The cable capacitance/inductance should be ≤ Ci/Li (e.g. Ci=4.16nF, Li=0.15mH) to avoid safety risks caused by exceeding the limit.

Explosion proof type requirements:

Power off and wait for 15 minutes before opening the lid to ensure the safety of the internal gas;

The cable sealing sleeve must comply with the IEC 60079-1 standard and be sealed with certified blind plugs for entry purposes;

When the shell is damaged (such as the observation window breaking), it should be immediately stopped to avoid the failure of explosion-proof performance.

Maintenance and troubleshooting

1. Daily maintenance and regular inspections

Routine inspection (weekly):

Pointer/display screen: Confirm that the flow indication matches the actual working conditions without any jamming or jumping;

Sealing state: The flange and cable sealing sleeve have no leakage, and the shell has no corrosion;

Explosion proof mark: The label is clear, without wear or detachment.

Regular maintenance (every 6 months):

Cleaning: The measuring tube and float need to be disassembled and cleaned (avoiding the use of corrosive solvents), and the magnetic properties of the float should be checked for normal operation;

Calibration: The electronic transmitter needs to be verified for 4-20mA output accuracy through a HART communicator, and the limit switch needs to be tested for contact action reliability;

Grounding inspection: The grounding resistance is ≤ 100 Ω, and the grounding terminal is not loose.

2. Common faults and troubleshooting

Possible causes and solutions for the fault phenomenon

The pointer is unresponsive/stuck, the float is stuck by impurities, and the inner wall of the measuring tube is scaled. Disassemble and clean the float and measuring tube, and replace the float if necessary

Electronic transmitter has no output power supply fault, calibration EEPROM is missing, wiring is loose. Check power supply (24VDC ± 10%), reinsert EEPROM, and tighten wiring terminals

HART communication failure, load resistance not between 250-600 Ω, pole address conflict, adjust load resistance, reset unique pole address (1-63)

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands