Yokogawa SC200 Intelligent Two Wire Conductivity Transmitter System (IM12D08B01-01E)

(2) Installation steps

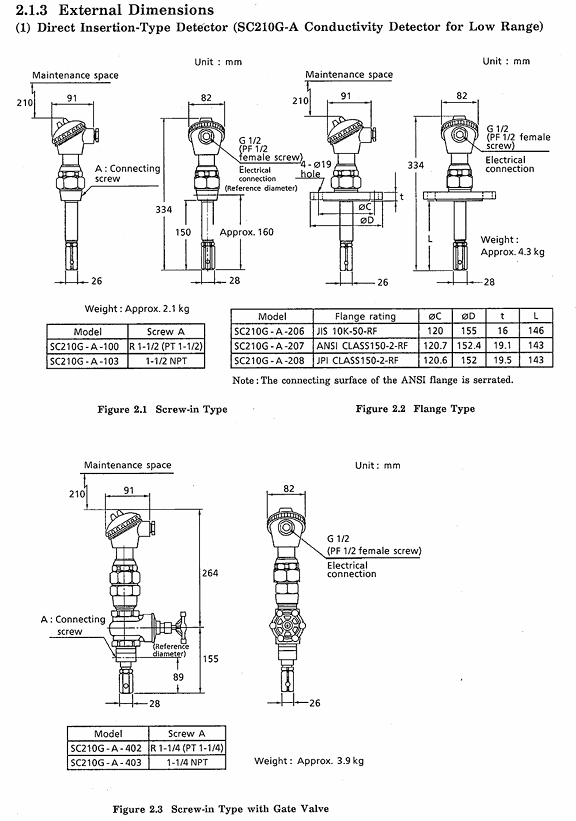

Direct insertion type: thread type wrapped with sealing tape and screwed into the interface, flange type needs to add gaskets and evenly tighten 4 bolts;

Flow type: fixed to the installation pipe or wall, adjust the direction of the terminal connection port (can rotate by loosening the union nut);

Pipeline connection: Use rigid vinyl chloride pipes (nominal 16) or PP pipes for PP supports, and SUS304/316 pipes (nominal 15) for SCS14 supports. The recommended flow rate is ≤ 20 L/min to avoid the mixing of bubbles.

2. Installation and wiring of transmitters

(1) Installation method

Pipeline installation: fixed to a nominal 50A pipeline (vertical/horizontal) using a dedicated bracket;

Panel installation: The panel opening size is 156 × 121 mm (tolerance+1.1mm), fixed with panel brackets;

Wall installation: Process 3 M8 threaded holes on the wall with a spacing of 70mm, and fix them with wall brackets.

(2) Wiring specifications

Requirements and steps for wiring types

Detector specific cable - SC210G (2 electrodes): 3/5/10m dedicated cable, connecting transmitter terminals 11 (T1), 12 (T2), 13 (C1), 14 (C2);

-SC211G (4 electrodes): 5.5/10m cable with connector, directly inserted into the detector interface, with the other end connected to transmitter terminals 11-16;

2-core shielded cable (outer diameter 6-12mm) is used for transmitting signal cables, with a maximum length of 2000m for non explosion proof systems and 700m for explosion proof systems. The shielding layer is connected to the safety barrier grounding terminal (explosion-proof) or the transmitter grounding terminal (non explosion-proof), with a grounding resistance of ≤ 10 Ω;

Grounding Wiring Non Explosion proof System: The M4 grounding terminal at the bottom of the transmitter is grounded with a wire of ≥ 2 mm ² (JIS Class 1 grounding, resistance ≤ 100 Ω); Explosion proof system: Only grounded through safety barriers, the transmitter is not grounded separately.

Operation and parameter settings

1. Operational hierarchy and mode

The system operation is divided into three levels, with clear functions and permissions at each level:

Operational hierarchy, permission scope, core mode/function

Operational level daily monitoring and basic operations (no need to open the cover) - Measurement mode: display conductivity, temperature, output current;

-Calibration mode: Perform standard solution calibration;

-Display selection: Switch auxiliary data such as temperature, output value, electrode constant, etc;

-Signal Hold: Turn on/off signal hold (requires setting level permission).

Parameter configuration for level adaptation measurement scenarios (requires lid opening operation) - Output range: Set the conductivity range corresponding to 4mA/20mA (4mA value should be less than 60% x 20mA value);

-Maintain parameters: choose to maintain "previous value" or "fixed value" (fixed value 4~20mA adjustable);

-Temperature compensation: Choose NaCl characteristics or custom compensation (input conductivity at reference temperature).

Service level system underlying configuration (password required, only for initial startup or maintenance) - CODE 01: Select temperature sensor type (Pt1000/Ni100/NTC) and temperature unit (℃/℉);

-CODE 02: Set reference temperature (0~100 ℃);

-CODE 03: Select output characteristics (linear/polyline);

-CODE 05: Input electrode constant (including fine adjustment ± 19.99%);

-CODE 07: Select electrode type (2 electrodes/4 electrodes);

-CODE 09: Enable/disable fault burnout function (output 22mA in case of fault).

2. Key operational procedures

(1) Standard solution calibration (operational level)

Enter calibration mode (MEASURE → CAL → YES), immerse the detector electrode in a NaCl standard solution with known conductivity (concentration close to the upper limit of the range, temperature close to the reference temperature);

After the display stabilizes, press the YES key to record the current measurement value;

Enter the actual conductivity of the standard solution at the reference temperature and press the ENT key to complete the calibration;

If the deviation between the calibrated electrode constant and the input value of service level CODE 05 is greater than 20%, Err.3 will be displayed, and the concentration of the standard solution needs to be checked or the electrode needs to be replaced.

(2) Temperature compensation setting (setting level)

Enter temperature compensation mode (Setting → Temperature → YES);

Choose compensation method: NaCl characteristics (default) or custom characteristics (*%);

If customized, adjust the solution temperature to the reference temperature, read the current conductivity and input it, and the system will automatically calculate the compensation coefficient (-10~+10%/℃);

If the compensation coefficient is known, it can be directly input in the service level CODE 14, with priority higher than the calculated value at the setting level.

Maintenance and troubleshooting

1. Regular maintenance

(1) Detector maintenance

Electrode cleaning:

Low/medium range (SC210G): Wipe the electrode surface with a thin rod wrapped in degreasing cotton to avoid scratches;

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands