EMG Automation GmbH SV 1-10 servo valve

EMG Automation GmbH SV 1-10 servo valve

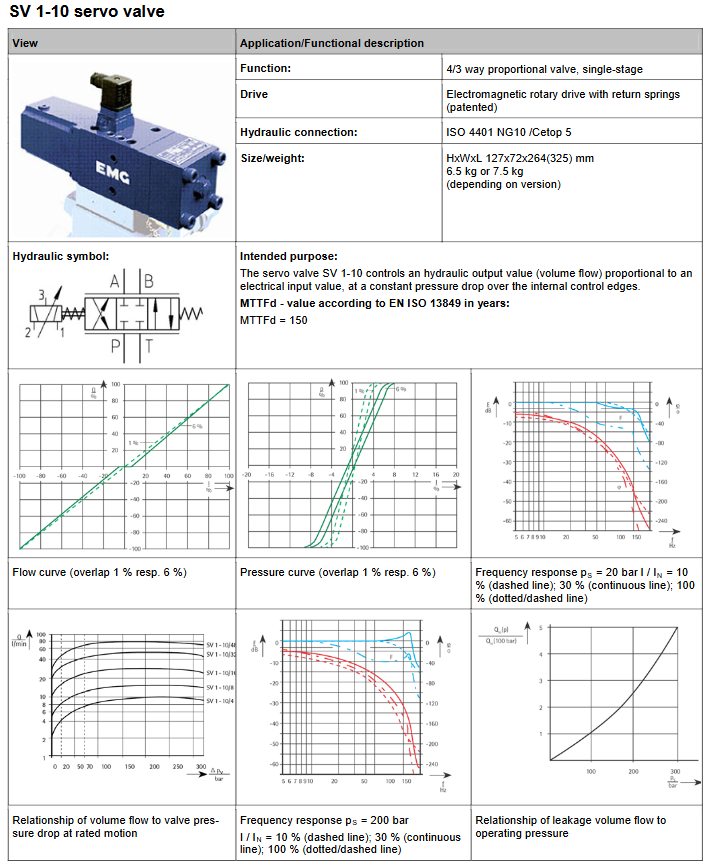

Product Core Overview

The EMG SV 1-10 servo valve is a single-stage 4/3-way proportional valve produced by EMG Automation GmbH in Germany. It adopts a patented electromagnetic rotary drive and reset spring design, complies with ISO 4401 NG10/Cetop 5 standards, and is suitable for precise control of flow and pressure in hydraulic systems. The equipment size is 127 × 72 × 264 (325) mm, and the weight is divided into 6.5kg and 7.5kg according to different versions. It can adapt to various hydraulic media such as mineral oil and is widely used in the field of industrial automation.

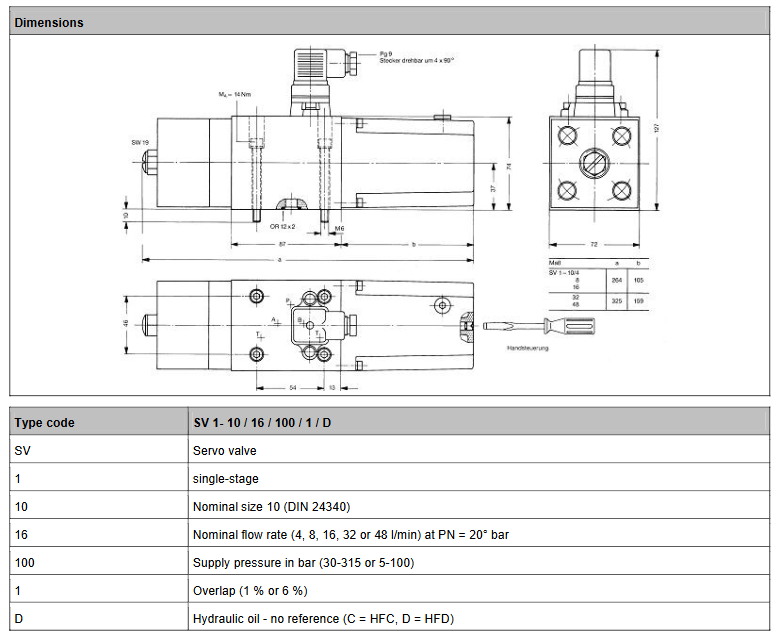

Model coding rules

The model code of SV 1-10 servo valve consists of 6 parts, each corresponding to specific parameters, which facilitates users to quickly identify product specifications. The specific rules are as follows:

Encoding position meaning optional parameters/description

Part 1 (SV) Product Type SV=Servo valve

Part 2 (1) Stage 1=single stage

Part 3 (10) nominal size 10=nominal size 10 (compliant with DIN 24340 standard)

Part 4 (e.g. 16) nominal flow rates 4, 8, 16, 32, 48 l/min (under PN=20 bar conditions)

Part 5 (e.g. 100) Fuel supply pressure 30-315 bar or 5-100 bar

Part 6 (such as 1/D) overlap amount/hydraulic oil type overlap amount: 1=1%, 6=6%;

Hydraulic oil: D=No specific reference (default mineral oil) C=HFC、D=HFD

Hydraulic parameter details

Hydraulic parameters are the core indicators for servo valve adaptation to hydraulic systems. The key parameters for different nominal flow rates (4/8/16/32/48 l/min) models are shown in the following table:

Hydraulic parameter specifications 4 l/min 8 l/min 16 l/min 32 l/min 48 l/min

Working pressure range (pS) with two pressure levels available: 30-315 bar or 5-100 bar (universal for all models)

The maximum allowable return oil pressure (pT) is uniformly limited to 30 bar for all models (universal for all models)

When the nominal flow rate (QN) Δ pN is 20 bar, the flow rate is 4 l/min, 8 l/min, 16 l/min, 32 l/min, and 48 l/min

When the nominal flow rate (QN) Δ pN=70 bar is 7 l/min, 13 l/min, 24 l/min, 46 l/min, and 70 l/min

External leakage flow rate without external leakage 0 (universal for all models)

Storage temperature range equipment storage environment requirements -20~+80 ° C (universal for all models)

Typical internal leakage flow rate (QO2) pS=100 bar, I=0 mA, t=50 ° C 0.4 l/min 0.6 l/min 1 l/min 1.5 l/min 2.2 l/min

Typical internal leakage flow rate (QO2) (Ex version, same as above) 0.4 l/min 0.7 l/min 1.2 l/min 1.8 l/min 2.8 l/min

Typical internal leakage flow rate (QO2) SV1-10/.../50/6 and Ex versions 0.7 l/min 1.2 l/min 1.8 l/min 2.8 l/min 3.8 l/min

Hysteresis flow control accuracy index<2%<2%<2.5%<2.5%<2.5%

Lag deviation control signal response stability<0.1%<0.1%<0.2%<0.2%<0.2%<0.2%

Correlation between sensitivity signal changes and flow response<0.1%<0.1%<0.2%<0.2%<0.2%

Nonlinear flow rate and linearity of control signals<2%<3%<4%<5%<6%

Asymmetric flow, consistency of flow in both directions<5% (universal across all models)

Overlap amount 1% Overlap amount model (../.../1) 0.5~2.5% (universal for all models)

Overlap amount 6% Overlap amount model (../.../6) 4-8% (universal for all models)

The influence of zero temperature drift on the zero flow point theoretically has no drift and cannot be measured (applicable to all models)

Recommended hydraulic medium compatible with mineral oil VG46 (compliant with DIN 51524) or HLP/HVLP VG46 (compliant with DIN 51524/ISO 6743-4); HFC and HFD require consultation with manufacturers

Recommended filtration precision: Hydraulic oil cleanliness requirements: Filtration grade 17/15/12 (ISO 4406:1999), grade 7 (SAE AS 4059), grade 6 (NAS 1638) (applicable to all models)

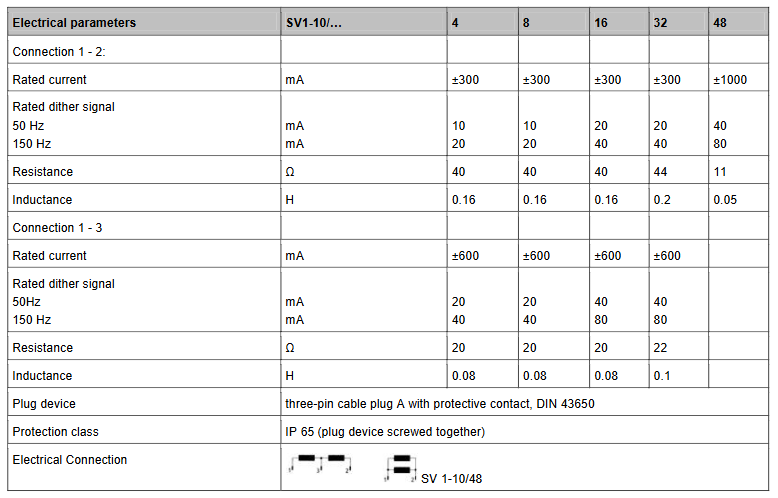

Electrical parameter details

Electrical parameters determine the compatibility between servo valves and control systems, mainly involving indicators such as current, resistance, inductance, etc., as follows:

Electrical parameter connection terminal (1-2) specifications 4 l/min 8 l/min 16 l/min 32 l/min 48 l/min

Rated current Normal operating current range ± 300 mA ± 300 mA ± 300 mA ± 300 mA ± 1000 mA

Rated jitter signal (50Hz) high-frequency signal compensation 10 mA 10 mA 20 mA 20 mA 40 mA

Rated jitter signal (150Hz) high-frequency signal compensation 20 mA 20 mA 40 mA 80 mA

Resistance coil resistance value 40 Ω 40 Ω 40 Ω 44 Ω 11 Ω

Inductance coil inductance value 0.16 H 0.16 H 0.16 H 0.2 H 0.05 H

Electrical parameter connection end (1-3) specifications 4 l/min 8 l/min 16 l/min 32 l/min 48 l/min

Rated current Normal operating current range ± 600 mA ± 600 mA ± 600 mA ± 600 mA-

Rated jitter signal (50Hz) high-frequency signal compensation 20 mA 20 mA 40 mA 40 mA-

Rated jitter signal (150Hz) high-frequency signal compensation 40 mA 40 mA 80 mA 80 mA-

Resistance coil resistance value 20 Ω 20 Ω 20 Ω 22 Ω-

Inductance coil inductance value 0.08 H 0.08 H 0.08 H 0.1 H-

General Electric Parameter Specifications

Three core cable plug with protective contacts, compliant with DIN 43650 standard

Protection level IP 65 (with plug tightened)

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands