Powell PowlVac ® CDR&GCB Series 4 Vacuum Circuit Breaker

Powell PowlVac ® CDR&GCB Series 4 Vacuum Circuit Breaker

Product Core Overview

PowlVac ® Series 4 vacuum circuit breaker is a new generation of metal armored vacuum circuit breaker launched by Powell Industries in the United States, suitable for medium and high voltage power systems ranging from 5kV to 38kV. Its design originated from the first PowlVac circuit breaker in 1982 and has been upgraded and optimized for multiple generations, combining compactness, high reliability, and low maintenance. The product focuses on 'Powered by Safety' ®” The concept provides multiple customized options (such as narrow body design, manual/automatic rack and pinion transmission, intelligent monitoring equipment), which can adapt to the space limitations of existing equipment and meet the protection needs of medium and high voltage circuits in industrial, power and other fields.

Safety regulations and qualification requirements

(1) Definition of Signal Words (in accordance with ANSI Z535.4-2007)

Clarify the risk levels of different safety warnings and guide personnel to identify the degree of danger:

DANGER: Emergency and dangerous situation, failure to avoid may result in death or serious injury.

Warning: Potential dangerous situations that may result in death or serious injury if not avoided.

CAUTION (with safety warning symbol): A dangerous situation that may cause minor/moderate injury.

CAUTION (unsigned): Precautions for operations unrelated to personal injury.

NOTICE: It only involves equipment operation specifications and has no safety risks.

(2) Qualified personnel qualifications (compliant with NFPA 70E) ®)

Operation and maintenance personnel must meet the following conditions:

Having received training on the construction and operation of high-voltage equipment, able to identify and avoid risks.

Master the safety operation procedures such as circuit on/off, grounding, and LOTO (Tag Out).

Familiar with the use of personal protective equipment (PPE) such as insulated gloves, safety helmets, and arc resistant clothing.

Have basic first aid skills.

(3) Key safety rules

Strictly prohibit live operation: all power sources must be disconnected before maintenance to ensure equipment grounding; Do not touch equipment when the control circuit is live.

Energy storage mechanism protection: The equipment adopts an energy storage spring mechanism. When releasing/operating, it is necessary to ensure that personnel and tools are kept away from moving parts to avoid accidental release of the spring causing injury.

Isolation requirement: It is not allowed to use only a disconnected circuit breaker as a means of isolating high-voltage circuits. The circuit breaker must be returned to the "test/disconnect" position or completely withdrawn.

X-ray risk: During high-voltage testing, the vacuum arc extinguishing chamber may generate X-rays. Personnel must maintain a distance of at least 1 meter from the equipment, and the circuit breaker must be fully opened or closed (half open testing is prohibited).

Interlock protection: The equipment is equipped with multiple interlocks (such as rack drive interlock, secondary disconnection interlock), and it is prohibited to modify or bypass the interlock device. In case of abnormalities, the manufacturer should be contacted.

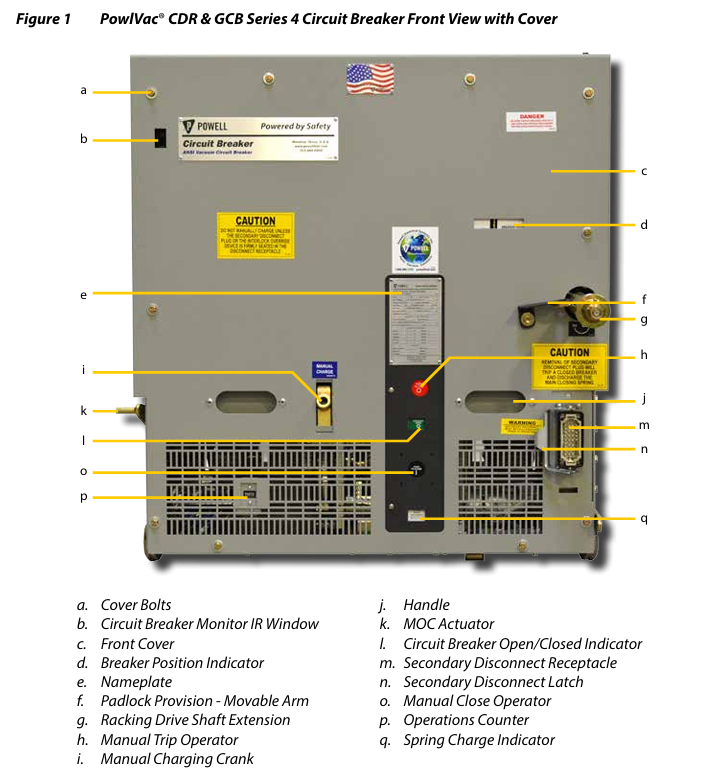

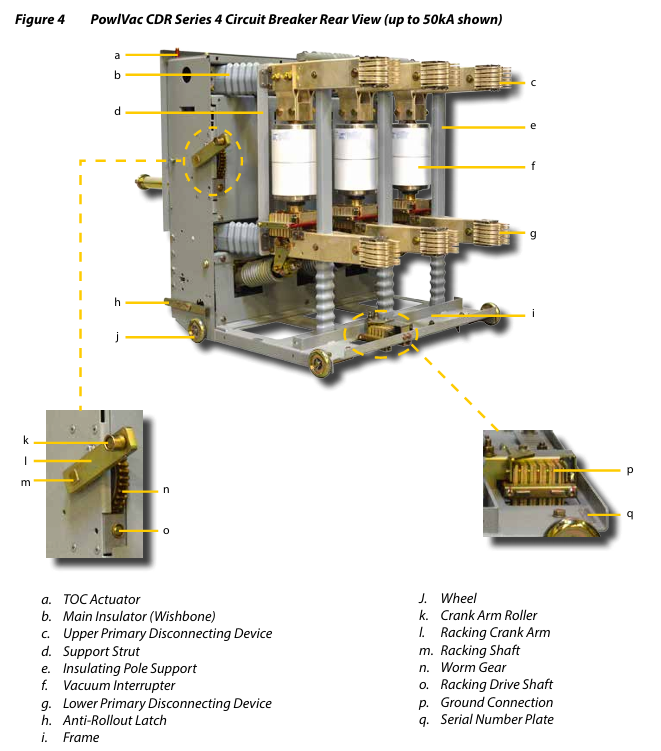

Equipment Description and Core Components

(1) Basic Structure and Function

The circuit breaker adopts a sealed vacuum arc extinguishing chamber to control the main circuit. The main circuit is connected to a multi contact primary disconnecting device through parallel copper busbars, and is supported by insulators as a whole; The front of the equipment is an operation panel (including indicator lights and manual operating components), which contains an energy storage mechanism, a rack and pinion transmission mechanism, an interlocking device, and auxiliary switches. It can switch between the "test/disconnect" and "connect" positions and is compatible with metal armored switchgear.

(2) Detailed explanation of core components

Stored Energy Mechanism

Mechanical structure: composed of main closing spring, camshaft, ratchet mechanism, retaining claw, etc., energy is stored by compressing the spring through a charging motor or manual crank, and the energy is released when closing to drive the vacuum arc extinguishing chamber contact to close; Equipped with a disconnect spring, it releases energy during disconnection to achieve rapid disconnection.

Electrical control: including charging motor, motor cut-off switch, anti pump relay (to avoid repeated opening and closing caused by continuous closing signals), closing coil, opening coil (primary/secondary), undervoltage trip device (optional), supporting 24VDC-250VDC/120VAC-240VAC control voltage.

Rack mechanism

Function: Drive the circuit breaker to switch between the "test/disconnect" and "connect" positions inside the switchgear, while controlling the opening and closing of the cabinet panel.

Position indication: The "Circuit Breaker Position Indicator" on the front panel displays the current status (fully displaying "BREAKER CONNECTED" as the connection position and "BREAKER TEST/DISCONNECT" as the test position).

Interlocking protection: Transmission is prohibited in the closed state; The secondary plug can only be unplugged in the "test/disconnect" position; When in the middle position, trigger the "free release" and prohibit closing.

Vacuum Interrupters

Core function: To achieve arc free breaking of the main circuit through a vacuum environment, different rated currents (25kA-63kA) correspond to different internal structures, and external support needs to be fixed through insulation.

Connection method:

25kA/36kA/50kA models: The arc extinguishing chamber is connected to the primary disconnect device through copper contact blocks, and the sliding contact components achieve multi-path current transmission.

63kA model: connected by copper castings, with built-in multi contact strips to reduce current density.

Switchgear interface components

One time disconnection device: 6 (2 per phase), connected to the fixed end of the cabinet to transmit the main circuit current.

Secondary disconnection device: located in the lower right corner of the equipment, it controls the transmission of power and signals through a plug, and can only be plugged and unplugged in the "test/disconnect" position.

Grounding connection: Spring loaded grounding contact, automatically grounded after insertion into the cabinet, ensuring reliable grounding at all positions.

Anti slip lock: To prevent the circuit breaker from accidentally slipping out of the cabinet, it needs to be manually pressed to unlock before it can be pulled out.

Installation process and operating specifications

(1) Reception and Storage

Receiving inspection: After unpacking, check whether the appearance of the equipment is damaged, and verify that the nameplate information (model, rated value, serial number) is consistent with the order; If there is any damage, immediately file a claim with the transportation company and notify Powell.

Storage requirements:

Indoor storage: temperature between 1 ° C and 60 ° C, humidity ≤ 60% (no condensation), space heater (if equipped) needs to be turned on, or desiccant needs to be placed.

Outdoor storage (outdoor only): Temporary protective covers are required to prevent pollutants from entering, and the temperature should be controlled above freezing point.

(2) Pre installation testing

Before the equipment is put into use, it needs to be tested in the following order to ensure its performance is qualified:

High voltage insulation integrity test:

Use a 2500V insulation resistance meter to measure phase to phase and phase to ground insulation, and record the values (no fixed qualified values, need to track trends).

AC voltage withstand test: According to ANSI C37.20.2 standard, the test voltage for 5kV equipment is 14.25kVAC, and for 15kV equipment it is 27kVAC, with no breakdown for 1 minute; After testing, it is necessary to ground and discharge for at least 1 minute to avoid residual charges causing electric shock.

Vacuum integrity test:

Recommended communication test: Apply 25kVAC in the open state for 10 seconds without breakdown.

DC test (optional): Use full wave rectification of 50kVDC for 5 seconds without breakdown; Prohibit the use of half wave rectification equipment to avoid misjudgment or damage to the arc extinguishing chamber.

Control circuit insulation test: Use a 500V/1000V insulation resistance meter or 1125VAC withstand voltage test for 1 minute. Before testing, disconnect the charging motor (to avoid damage).

Mechanical/Electrical Operation Inspection:

Mechanical operation: Insert the secondary disconnection simulator, manually charge (about 60 crank operations) until the "closing spring has stored energy", and manually open and close to verify that the status indication is normal.

Electrical operation: Verify the automatic energy storage, opening and closing coil action, and anti pumping function of the charging motor through the control circuit of the testing cabinet or switch cabinet.

(3) Cabinet installation and position switching

Insert into the "test/disconnect" position:

Align the cabinet track, push the circuit breaker into contact with the rack and crank and the cabinet slot, and the anti disengagement lock will automatically engage.

Insert the secondary plug and lock it, install the rack drive fixing component (non arc resistant cabinet), and close the cabinet door.

Switch to the 'Connect' position:

Open the "teardrop shaped" cover plate of the cabinet, insert the dedicated rack handle, rotate clockwise for about 22 turns until the position indicator displays "BREAKER CONNECTED"; When the handle torque reaches 35ft lb, the torque limiter is triggered and the rotation stops.

Extraction process:

Ensure that the circuit breaker is open and the spring is discharged. Rotate the handle counterclockwise to the "test/disconnect" position, unplug the secondary plug, press the anti release lock, and pull the circuit breaker out of the cabinet.

Maintenance process and cycle

(1) Maintenance cycle and basic requirements

Routine maintenance: Every 1000-2000 operations or once a year, the cycle needs to be shortened in harsh environments (high dust, high humidity, corrosive gases).

Post fault maintenance: After interrupting the short-circuit current near the rated value, it is necessary to immediately check the arc extinguishing chamber, contacts, and mechanical components.

Preparation before maintenance: Return the equipment to the "test/disconnect" position, disconnect all power sources and ground, and record the reading of the operation counter.

(2) Core maintenance project

Cleaning and Inspection:

Use a vacuum cleaner or dry cloth to remove dust, and prohibit the use of compressed air (to prevent dust from entering the bearings); Insulated components (such as arc extinguishing chamber supports and operating push rods) should be wiped with isopropanol, and the use of detergents is prohibited.

Check if the fasteners are loose, if the contacts are burned, if the energy storage mechanism components are worn, and if damaged parts need to be replaced in a timely manner.

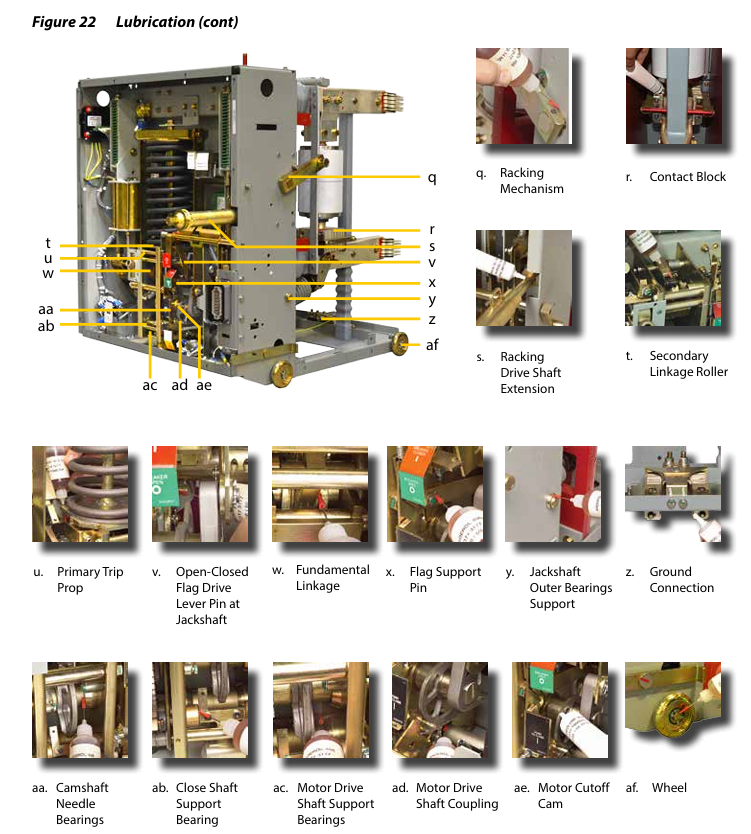

Institutional lubrication (using Powlube-104 kit)

A - Lubricating grease: Apply to moving parts such as camshaft bearings and closing lock shaft surfaces, thin coat and remove excess grease.

B - Lubricating grease: used for one-time disconnection contacts, grounding connection contacts, and other conductive contact surfaces to ensure good contact.

C - Lubricating oil: Drip onto bearings such as ratchet gears, connecting rod shafts, and rack and pinion transmission mechanisms, penetrating into the mating surfaces.

Maintenance of vacuum arc extinguishing chamber

Contact wear inspection: Measure the gap between the operating push rod lock nut and the spring yoke in the closed state. When the gap reaches the "end of life value" marked on the nameplate, the arc extinguishing chamber needs to be replaced.

Vacuum integrity retest: Repeat the vacuum test annually or during maintenance to ensure no leaks.

Institutional adjustment (only after major repairs)

Ratchet holding claw adjustment: By adjusting with eccentric bolts, ensure that the ratchet operates without any "knocking sound" and that manual/electric energy storage is smooth.

Adjustment of the opening system: Adjust the gap between the main opening support rod (0.005 "-0.015") to ensure reliable opening action. Do not trip when tested with a 0.090 "plug gauge, and trip when tested with a 0.030" plug gauge.

Lock check switch adjustment: Insert a 0.045 "plug gauge and adjust the switch position until the contacts are closed, ensuring that the switch is disconnected when opening and closed when resetting.

(3) Optional testing items

**Timing test * *: Closing time ≤ 80ms (coil energized to arc extinguishing chamber contact), opening time<35ms (3 cycles)/<55ms (5 cycles).

Main circuit resistance test: Measure the voltage drop with 100A DC and calculate the resistance value, which should comply with the limit values in the table (such as 15PV36CDR 3000A model ≤ 40 μ Ω).

Spare parts replacement and ordering

(1) Spare parts ordering requirements

Provide complete nameplate information: model, serial number, rated voltage/current/short-circuit current, control voltage.

Clearly describe the spare parts (such as "vacuum arc extinguishing chamber components"), quantity, and if referring to the illustrations in the manual, indicate the location of the components.

(2) Key spare parts and replacement process

Spare part name applicable scenario replacement precautions

The contact wear of the vacuum arc extinguishing chamber component exceeds its service life and the vacuum leakage is 25kA-50kA. The model can be replaced on site (refer to manual 01.4SM.1900); The 63kA model requires professional personnel to operate and Powell needs to be contacted

Sliding contact assembly (≤ 50kA) with contact erosion and exposed copper substrate can be disassembled and reversed for use (only the upper end is worn). After replacement, apply B-grease and bolt torque of 8-12 ft-lb

When the closing/opening coil burns out or fails to operate, the control power supply needs to be disconnected to ensure that the coil voltage is consistent with the prototype number (such as 24VDC/120VAC)

The charging motor does not rotate and energy storage fails. Refer to manual 01.4SM.1200 for reference. After replacement, test the motor direction and energy storage efficiency

Poor grounding of grounding connection components and oxidation of contacts. When disassembling, it is necessary to raise the equipment and apply B-lubricating grease after replacement to ensure reliable grounding

(3) Recommended spare parts list

It is recommended to reserve 1 set of spare parts for every 10 circuit breakers:

Vacuum arc extinguishing chamber (corresponding model), sliding contact assembly, closing/opening coil, charging motor, anti pump relay, locking inspection switch, lubrication kit (Powlube-104).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands