Honeywell System 57 5704 Control System

Honeywell System 57 5704 Control System

Product positioning and core functions

The Honeywell System 57 5704 control system is a microprocessor controlled device used for industrial gas detection, belonging to the System 57 product family. Its core function is to monitor industrial gas detectors installed on site, achieve multi-channel gas concentration monitoring, alarm triggering, and system management. It is suitable for indoor non hazardous areas and should not be exposed to rainwater or moisture. It is also not designed for use in hazardous areas. The system supports catalytic and 4-20mA input types of gas sensors, with flexible alarm configuration, remote control, and self diagnostic capabilities. Calibration, maintenance, and parameter settings can be performed through engineering cards, and it is also compatible with extended functions such as Modbus communication and event printing.

System composition and hardware specifications

(1) Core hardware module

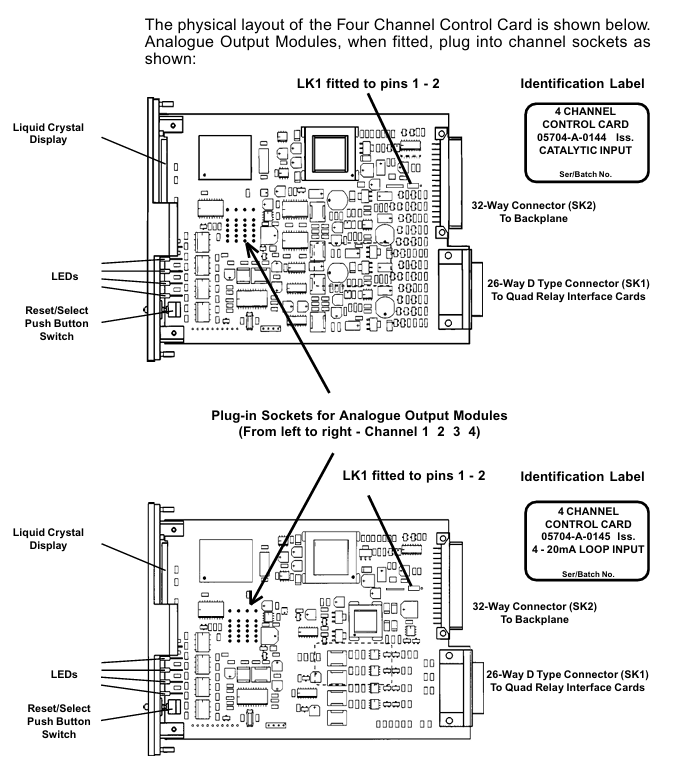

Four Channel Control Card

Type differentiation: divided into catalytic input type (model 05704-A-0144) and 4-20mA input type (model 05704-A-0145). The former supports catalytic gas sensors and provides constant current drive (adjustable from 90-315mA), while the latter is suitable for 4-20mA circuit power supply sensors with a measurement range of 0-25mA.

Display and indication: Equipped with four LCD displays (25 segment analog bar, 4-digit digital display, 4-digit message display, icon area), 4 channel LEDs (CHL1-CHL4) and 1 Attention (ATTN) LED, which can distinguish A1/A2/A3 alarm, STEL/LTEL alarm, fault, suppression and other states by LED flashing frequency/color.

Core parameters: Initial accuracy ± 1%, alarm set point resolution 1% of full range, electronic drift<± 3%/6 months, operating voltage 18-32V DC, catalytic type maximum power consumption 12.8W, 4-20mA type maximum power consumption 8.3W.

relay interface module

Quad Relay Interface Card (model 05704-A-0121): Provides 4 Single Pole Double Throw (SPCO) relays, supporting latch/non latch, power on/off action modes, and rated relay contacts 5A@110 /250V AC or 32V DC, supporting interface connection between sensors and control cards, with a maximum power consumption of 1.7W.

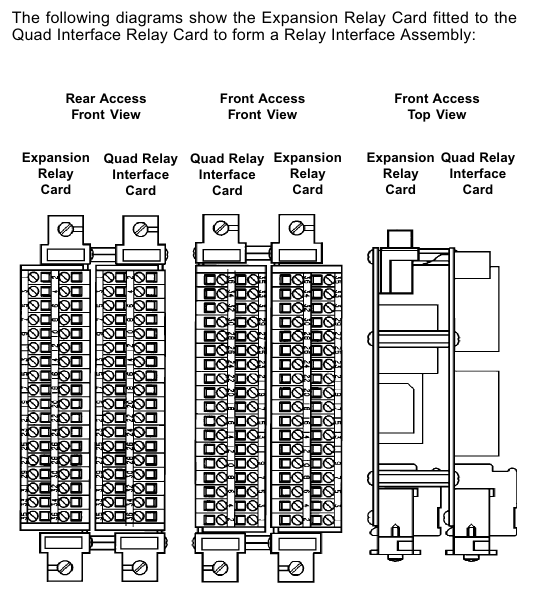

Relay Interface Assembly (model 05704-A-0131): It consists of four relay interface cards and an extended relay card, including 12 SPCO relays and 4 Single Pole Single Throw (SPST) relays, occupying 2 card slots, with a maximum power consumption of 6.5W, suitable for scenarios that require more relay outputs.

Engineering Card (Model 05701-A-0361)

Functional positioning: The core module for system configuration, calibration, and maintenance, equipped with green power LED, red unlock LED, as well as directional keys (up/down), confirm/cancel keys, function keys (BEAD mA, ALARMS, ZERO, SPAN, etc.).

Core Capability: Supports sensor bridge current regulation, alarm threshold setting and relay testing, zero/range calibration, system clock setting, can be configured and data printed through RS232 interface connected to printer or PC, with a power consumption of approximately 1.5W.

DC Input Card (Model 05701-A-0325)

Function: Provides a system DC power supply interface, supports two independent power inputs (such as main power and backup battery), has diode isolation and 10A anti surge fuse, supports 2.5mm ² (14 AWG) wire terminals, and operates at a voltage of 18-32V DC.

other modules

Analog output module: divided into current absorption type (04200-A-0145) and current source type (04200-A-0146), output range 0-20mA or 4-20mA software optional, linearity ± 2% of full range, supporting external power supply of 18-40V.

Expansion module: including event printing module (05701-A-0314), Modbus interface module (RS232 type 05701-A-0313, RS485/422 type 05701-A-0312), alarm update module (05701-A-0309), etc., used to expand communication and alarm functions.

(2) System rack and cabinet

Rack: available in full 19 inch and half 19 inch widths, supporting front or rear wiring, including engineering cards, DC input cards, and interconnecting cables (front wiring type), made of galvanized steel, with M5 grounding terminal bolts, weighing approximately 287.6-217.6g including modules (depending on model).

Cabinet: divided into 8 channels (model 05701-A-0452) and 16 channels (model 05701-A-0451), made of low carbon steel, RAL 7015 dark gray, equipped with knockout cable sealing sleeves (8 channels include 2 M25, 8 M20, etc.), weighing 10kg for 8 channels and 13.5kg for 16 channels.

(3) Power supply unit

AC-DC power supply unit: divided into 8 channels (model 05701-A-0406) and 16 channels (model 05701-A-0405), input 85-264V AC (47-440Hz) or 110-340V DC, output 24V DC ± 10%, can be upgraded by adding a 50W switch module (model 05701-A-0440) (maximum 100W for 8 channels, maximum 200W for 16 channels), with overload protection (triggered by 105% rated load, automatic recovery), maximum leakage current 0.75mA/50W module.

Installation and wiring requirements

(1) Environment and Location

For indoor use only, avoid heat sources, moisture, and physical damage. The ambient temperature is -5-55 ℃ (ATEX certification system is 0-55 ℃), the humidity is 0-90% RH (no condensation), and the altitude is ≤ 2000m.

The installation of sensors should follow the characteristics of gas density (installation height for gas sensors lighter than air, installation height for sensors heavier than air), avoid areas where airflow is obstructed, quiet corners, and near heat sources, and be easy to maintain.

(2) Wiring and Connection

Sensor wiring: It is necessary to use cables with grounding and external shielding to avoid parallel interference sources such as AC power lines and motors. The maximum length of the cable depends on the type of sensor and the cross-sectional area of the wire (for example, when using 2.5mm ² wire for catalytic sensors, the maximum length is 2500m, and when using 2.5mm ² wire for 4-20mA sensors, the maximum length is 16000m). The shielding layer is only grounded at the cabinet end.

Power and relay wiring: The rated current of the power cable should be greater than the maximum load. If the relay cable is connected to an AC power source, a 5A fuse is required. The DC input card and relay interface card terminals support 2.5mm ² wires. When wiring, the power should be disconnected to avoid short circuits.

(3) Power configuration

The total power consumption of the system needs to be calculated through the "power budget table", depending on the sensor type, number of channels, and module configuration; When there are more than 8 catalytic control cards, it is recommended to supply power separately through the four relay interface card to avoid the backplane current exceeding the 8A limit.

Supports dual input of main power supply and backup battery, with diode isolation achieved through a DC input card. The backup battery needs to be compatible with 18-32V DC specifications.

Operation and maintenance process

(1) Basic operation (without engineering key)

Control card reset and selection: Short press the RESET/SET button to reset inactive alarms and clear peak display; Long press and hold for 1.5 seconds to select the control card, then use the up and down keys on the engineering card to select the channel; Press and hold for 5 seconds to perform an extended reset (clear maximum/minimum readings, reset STEL/LTEL timer).

Basic functions of the engineering card: It can view the catalytic sensor bridge current (BEAD mA key), alarm threshold (ALARMS key), sensor signal (SIGNAL key), and system clock (CLOCK key). Calibration, suppression, and other operations cannot be performed without a key, and the selection will be automatically canceled after 30 seconds of timeout.

(2) Engineering operation (requires inserting the engineering key to unlock)

Channel suppression (INHIBIT key): After selecting a channel, press the INHIBIT key to switch the suppression state. During suppression, the channel LED will remain amber and the relay will be locked in an inactive state to avoid false alarms during calibration or troubleshooting.

Calibration process

Zero calibration (ZERO key): Ensure that the sensor is in a gas free environment, press the ZERO key, wait for the signal to stabilize (message displays "STANBLE"), and then press the confirm key. The system will automatically set the current signal to zero. If the signal exceeds the range, an error will be displayed.

Range calibration (SPAN key): Suitable for calibrated sensors, press the SPAN key to set the target range concentration, introduce the corresponding concentration standard gas, confirm after the signal is stable, and the system updates the range parameters; The new sensor requires the "1st SPAN" key to perform the first range calibration and record the initial sensitivity for lifespan monitoring.

Alarm and Relay Testing: Press the ALARMS key to set the A1/A2/A3/SETL/LTEL threshold. After switching to "TEST" mode, simulate gas concentration changes by pressing the up and down keys to verify whether the alarm LED and relay actions are normal. During testing, be sure to release the suppression to trigger the external relay.

(3) Maintenance and troubleshooting

Regular maintenance: It is recommended to check the terminal fastening, LED status, sensor signal and alarm function every year. The catalytic sensor needs to be calibrated regularly (according to the sensor manual). When the sensitivity of the catalytic sensor drops below 50% of the initial value, the system displays "Lifetime Expired" and the sensor needs to be replaced.

Fault diagnosis: Identify the problem through the error codes displayed on the control card message (such as ER97 for EEPROM fault, ER87 for over range fault, ER83 for bridge current fault), and check the power supply, wiring, and sensor status using the "troubleshooting table". Hardware faults require replacement of the corresponding module.

Data recording: It can be connected to an RS232 printer through an engineering card, and long press the up and down keys to print single channel status or overall rack summary data, including sensor type, calibration date, alarm threshold, relay configuration, and other information.

Compliance and safety requirements

(1) Certification and Standards

Compliant with EN50054/57/58 (General Requirements and Performance for Combustible Gas Detection), EN50271 (Software and Digital Technology), EMC Directive 89/336/EEC (EN50270:1999), Low Voltage Directive 73/23/EEC (EN 61010-1), ATEX certification based on EC Type Examination Certificate BVS 04 ATEX G 001 X, suitable for Zone 2 hazardous areas (requiring tested enclosures).

(2) Safety operation standards

Installation and maintenance should be carried out by professionals, and wiring should be operated after power failure to avoid equipment damage caused by incorrect sensor wiring; When used in hazardous areas, it is necessary to comply with the installation standard EN 60079-14 to ensure the enclosure protection level and explosion-proof requirements; The data read by Modbus is only used for visualization or recording and cannot be used for safety related control to avoid Modbus write operations.

Ordering and Accessories

Core module ordering models: Control card, relay interface card, engineering card, DC input card, etc. The core module models are clear, and the power unit, cabinet, and rack need to be selected according to the number of channels and installation requirements (such as 8-channel cabinet 05701-A-0452, 16 channel power supply 05701-A-0405).

Optional attachments: including blank panel (05701-A-0365), engineering key kit (05701-A-0550), interconnect cable (05704-C-0160), liquid tight connector kit, etc. Expansion modules such as Modbus interface and event printing module need to be ordered separately.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands