YOKOGAWA CENTUM VP Integrated Production Control System (TI33J01A10-01EN)

YOKOGAWA CENTUM VP Integrated Production Control System (TI33J01A10-01EN)

System positioning and development background

1. Core positioning

CENTUM VP is the 8th generation distributed control system (DCS) of Yokogawa, designed based on "high availability, flexible scalability, and full lifecycle cost optimization". It can achieve integrated management of factories from "control safety asset production", support monitoring scale of up to 1 million tags, and adapt to the needs of complex factories from small to super large.

2. Development process

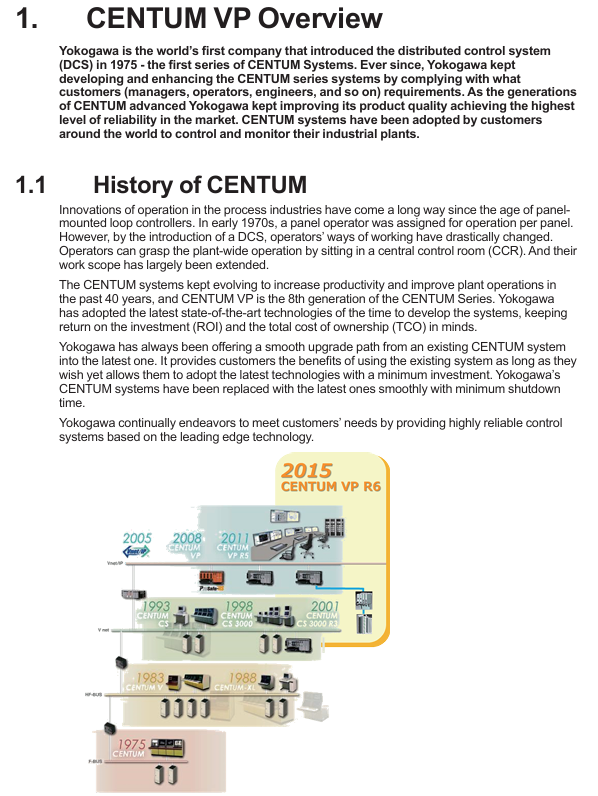

In 1975, Yokogawa launched the first CENTUM series DCS, pioneering distributed control;

Iterative upgrade: After 7 generations of products including CENTUM-XL, CENTUM V, CENTUM CS, etc., it gradually evolved to CENTUM VP after 2005, released R6 version in 2015, and updated to the 6th edition manual in 2019;

Market size: As of March 2019, over 28900 projects have been delivered globally, with core applications in fields such as oil and gas (with the highest proportion), petrochemicals, and chemicals. Europe, the Middle East, and Asia are the main markets.

Core advantages of the system

CENTUM VP focuses on the six core advantages of "operation, engineering, control, production management, maintenance, and project" scenarios, as follows:

Core advantages of the scene

On the operational level, there is a unified user interface that integrates control, security, and asset data to avoid information overload;

2. Continuous optimization: Support the solidification of best practices and scenario based operation suggestions.

Engineering level 1. Flexible design: Based on the AD Suite engineering environment, it supports "modular engineering" (independent of hardware configuration design control logic) and "non modular engineering" (hardware design before design);

2. Efficient reuse: Modules can reuse historical project experience to shorten project cycles.

Control layer 1. Ultra high reliability: FCS (Field Control Station) availability reaches 99.99999%, supporting fault avoidance, fault-tolerant operation, and rapid recovery;

2. Flexible I/O: Supports N-IO modules (software configured with DI/DO/AI/AO signals) to reduce wiring costs.

Production management 1. Fast PDCA cycle: Integrate MES with enterprise systems through S95/B2MML standards;

2. Security integration: Built in control network security authentication to ensure data transmission security.

Maintenance level 1. Online upgrade: supports non-stop modification and upgrade, with no single point of failure risk;

2. Long term compatibility: Maintain backward compatibility during 40 years of product iteration to protect historical investments.

Project Level 1: Rapid Delivery: Integrating DCS, SIS (Safety Instrumented System), PIMS (Factory Information Management System), etc. to reduce integration risks;

2. Cost controllable: Label authorization is only available in three levels: 8000 points (small), 100000 points (medium to large), and 1 million points (multi factory linkage).

System architecture and core components

CENTUM VP adopts a "3+N" infrastructure (3 core components+N extension components), which is interconnected through Vnet/IP control network and supports flexible expansion.

1. Three core components

(1) Human Interface Station (HIS)

Positioning: Operator monitoring and operation terminal, based on Intel x86 PC+Windows system, installed with operation monitoring software;

Features: 1 No single point of failure: Multiple HIS can backup each other without relying on servers;

2. Flexible display: Supports 16:10/4:3 widescreen display, multi monitor linkage, and windows can be moved across screens;

3. Compliant with standards: Following EEMUA # 191 Alarm System Design Guidelines, integrated with Alarm Management Software (CAMS).

(2) On site Control Station (FCS)

Positioning: System core controller, independently designed and manufactured by Yokogawa, responsible for control calculation and I/O signal processing;

Hardware structure: divided into cabinet type and rack type, including FCU (field control unit)+node unit (installation of I/O modules), supporting multi node unit expansion of I/O points;

Reliability design: 1 Dual redundancy: processors, power supplies, I/O modules, and networks are all redundant;

2. Fault handling: seamlessly switch to the backup module in case of a fault, and support online replacement of the faulty module;

3. Independent operation: Basic control can be achieved without the need for HIS, and data and logic are stored locally.

(3) Control network (Vnet/IP)

Technical specifications: Compliant with IEEE802.3 Ethernet standard, 1Gbps bandwidth, dual redundancy;

Core features: 1 Deterministic communication: Yokogawa proprietary protocol ensures real-time performance, HIS data update interval ≤ 1 second;

2. Precise synchronization: supports time synchronization within 5ms for each site;

3. Open interconnection: Non CENTUM components (such as third-party PLCs and instruments) can be connected.

2. Extension components (configured as needed)

Component Name Function Positioning

Install AD Suite engineering software on the Engineering Station (ENG), responsible for system configuration, control logic design, and parameter debugging; Support "modular" and "module free" projects.

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

Email:wang@kongjiangauto.com