Allen Bradley 150 Series SMC Dialog Plus Controller

Installation specifications

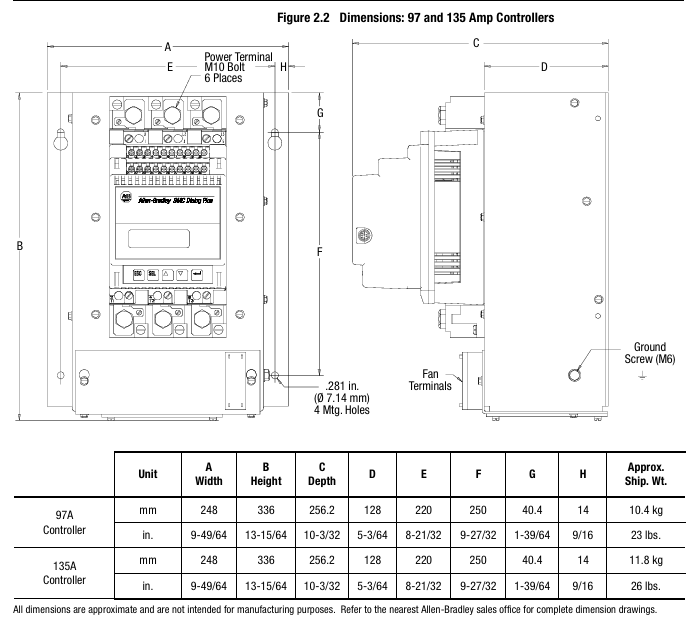

The radiator fins need to be installed vertically, with at least 15cm of space reserved above and below to ensure air circulation; Grounding should be connected to the controller's dedicated grounding screw/terminal post, in accordance with the IEC 5019 grounding identification standard.

(3) Wiring: Power and Control Circuit Configuration

Power wiring

The input (L1/L2/L3) is connected to the power grid, and the output (T1/T2/T3) is connected to the motor. Different current levels of terminals are compatible with different wire specifications (such as 24-54A supporting 2.5-25mm ² wires, 1000A supporting 50-240mm ² wires), and the terminals need to be tightened according to the torque specified in the manual (such as 0.8N · m for 2.5-6mm ² wires).

Suggest installing a fast current limiting fuse (such as 24A with 170M 3610-63) to protect the SCR from overcurrent damage; The power factor correction capacitor needs to be installed on the input side of the controller to avoid damage to the SCR caused by capacitor discharge.

Control wiring

The control power supply supports 100-240V AC (± 15%/± 10%) or 24V AC/DC (± 15%/± 10%), and requires separate connection to terminals 11/12. The control module has a power consumption of 40VA, and the cooling fan requires additional power supply (such as 45VA for 97A fans).

Control terminal functions: terminals 13 (enable), 16 (start), 17 (stop), 19-20 (auxiliary contacts 1&2, Form C, can be set to "normal/rated speed"), 29-30 (auxiliary contact 3, can be set to "normal/fault"), some terminals (such as 25-28) are used to connect converter modules or communication modules.

Typical wiring scheme: Provides 12 scenario wiring diagrams, including standard control, dual ramp start, bypass operation, reverse control, manual automatic (SCANPort) control, etc. If the bypass configuration requires the use of an 825 converter module to maintain current monitoring and avoid loss of protection function after controller bypass.

(4) Programming: Parameter Setting and Operation

Programming interface: Operated through the built-in 2-line 16 character backlit LCD and 4 keys (ESC/SEL/up and down arrows), the menu is divided into 4 levels (operation layer → mode layer → group layer → parameter layer), supports password protection (prevents unauthorized modification) and "search" mode (only displays non default parameters).

Core parameter group

Basic Setup: Configure startup mode, ramp time, current limit, energy-saving mode, auxiliary contact function, etc., suitable for fast startup.

Advanced Setup: includes dual ramp parameters, overvoltage/undervoltage thresholds, voltage imbalance protection, phase balance, hourly startup times, etc., suitable for complex scenarios.

Calibrate: Input the motor nameplate data (rated current, service factor, motor code, etc.), and use a true RMS clamp meter (accuracy ± 1%) to calibrate the current measurement and ensure the accuracy of the protection function.

Parameter storage: Parameters are stored in RAM by default (lost during power failure) and need to be manually saved to EEPROM (non-volatile). It supports restoring factory default values.

(5) Diagnosis and Troubleshooting: Problem Localization and Resolution

Fault display: The first row of the LCD displays the fault type (such as "OVERLOAD"), the second row displays the fault code (such as "F7"), and the fault buffer stores the last 5 fault records.

Common faults and solutions

Overload (F7): Check if the motor load is too large, if the overload level matches the motor, and if the FLC parameters are entered correctly.

Phase loss (F1-F3): Check if the power grid incoming line and motor wiring are loose, and if the fuse is blown.

SCR open circuit (F23-F25): Measure the resistance between the incoming and outgoing lines of the power module (normally>10k Ω). If there is a short circuit, replace the power module.

Communication Failure (F21): Check if the human-machine interface or communication module connected to SCANPort is disconnected, and if the Logic Mask parameter is set to 4 (enabling communication control).

Maintenance operation: When disassembling the control module, power off first, mark the wires, and then loosen the fixing screws to avoid bending the interface pins; The resistance inspection of the power module requires the use of an ohmmeter to measure the feedback resistance, gate resistance, and thermistor. If they do not meet the standards, the module needs to be replaced.

(6) Serial Communication: Remote Control and Data Interaction

Communication interface: SCANPort is standard and can be connected to 1201 human-machine interface module (programming, start stop control) or 1203 communication module (supporting protocols such as Remote I/O, DeviceNet, DH-485, etc.).

Control Enable: Parameter 85 (Logic Mask) needs to be set to 4 to enable remote control; PLC can send start stop, fault reset, option commands (such as pump stop), receive controller status (running, fault, rated speed) and metering data (current, power).

Communication example: Provide ladder diagram program examples for controllers such as SLC 500 and PLC 5, such as implementing block transfer (BTW/BTR) through Remote I/O, reading motor current, power and other parameters, or performing explicit message transmission through DeviceNet (such as reading fault codes).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands