Allen Bradley 150 Series SMC Dialog Plus Controller

Allen Bradley 150 Series SMC Dialog Plus Controller

Core framework and scope of application

The document is divided into 10 core chapters and 4 appendices, with a clear and progressive structure based on the logic of "operation process+technical details". The applicable product is SMC Dialog Plus controller (Bulletin 150), which supports rated current of 1-1000A, voltage of 200-480V AC or 200-600V AC, and frequency of 50/60Hz. It can control three-phase squirrel cage motors and is suitable for various scenarios such as motor starting, speed regulation, braking, etc. in the industrial field, such as motor control of pumps, fans, compressors, conveyor belts and other equipment.

Core chapter content sorting

(1) Product Overview: Functions and Core Features

Startup mode: Provides 4 standard startup modes to meet different load requirements

Soft Start: The initial torque (0-90% locked rotor torque) and acceleration ramp time (0-30 seconds) can be adjusted, and the motor automatically switches to full pressure operation after reaching rated speed, suitable for general loads.

Current Limit Start: Limit the maximum starting current (50-600% of the rated motor current) for 0-30 seconds to avoid excessive starting current impacting the power grid, suitable for scenarios with limited transformer capacity.

Dual Ramp Start: Supports two independent soft start parameters (ramp time, initial torque) that can be switched and used to adapt to equipment with large load fluctuations (such as crushers and mixers).

Full Voltage Start: Output full voltage within 1/4 second, suitable for loads that require quick start-up (such as emergency backup motors).

Additional features: Optional Kickstart, providing short pulses (0.0-2.0 seconds) of 550% rated current to assist in starting high static friction loads (such as heavy-duty conveyor belts).

Protection and diagnostic functions: ensuring the safety of motors and controllers in all aspects

Overload protection: Supports overload levels of 10/15/20/30, can be manually/automatically reset, requires input of motor rated current (FLC), service factor and other parameters, monitors motor thermal utilization rate through thermal memory algorithm, and triggers protection when reaching 100%.

Fault protection: covering stalling (0.0-10.0 seconds delay), jamming (current threshold 0-999% FLC, delay 0.0-10.0 seconds), underload (0-99% FLC, delay 0-99 seconds), overvoltage/undervoltage (delay can be set based on rated voltage percentage), voltage imbalance (0-25% threshold), phase loss, SCR open circuit (shutdown after 3 failed starts), overtemperature (monitoring SCR temperature, cutting off output when exceeded), etc.

Additional features: phase balance (requires 825 converter module), energy-saving mode (reduces output voltage and losses under light load, not suitable for bypass contactor scenarios), hourly start limit (0-99 times), to avoid frequent motor overheating during startup.

Measurement and status monitoring: real-time feedback of operational data

It can monitor parameters such as three-phase voltage, three-phase current, power (kW), energy consumption (kWh), power factor (displacement power factor), motor thermal utilization rate, and operating time. Some functions (such as current measurement) require the use of an 825 converter module during bypass operation.

Control options: 6 optional functions, expanding the application scenarios of the controller

Soft Stop: The voltage ramp drops for 0-60 seconds, extending the load shutdown time and avoiding water hammer effects in pump equipment.

Pump Control: The start (0-30 seconds) and stop (0-120 seconds) times can be set to smoothly accelerate/decelerate and reduce pipeline pressure fluctuations.

Preset Slow Speed: Provides low-speed Jog function with forward 7%/15% and reverse 10%/20% rated speed, used for equipment positioning or debugging, and cannot operate for a long time (due to insufficient motor heat dissipation).

Intelligent Motor Braking (SMB): No additional equipment is required, apply a braking current of 0-400% FLC, automatically cut off at zero speed, and shorten downtime (such as elevators and centrifuges).

Accu Stop: Combining SMB braking with preset low speed, brake to low speed before stopping, suitable for scenarios that require precise positioning (such as packaging machines).

Slow Speed with Braking: Braking can be triggered after low-speed braking, balancing debugging and safe shutdown.

(2) Installation: Environment and hardware requirements

Reception and Storage

Before opening the box, it is necessary to check that the product model is consistent with the order and confirm that there is no transportation damage; Long term storage should meet the requirements of temperature -20 ° C~+75 ° C, humidity 0% -95% (no condensation), and avoid corrosive environments.

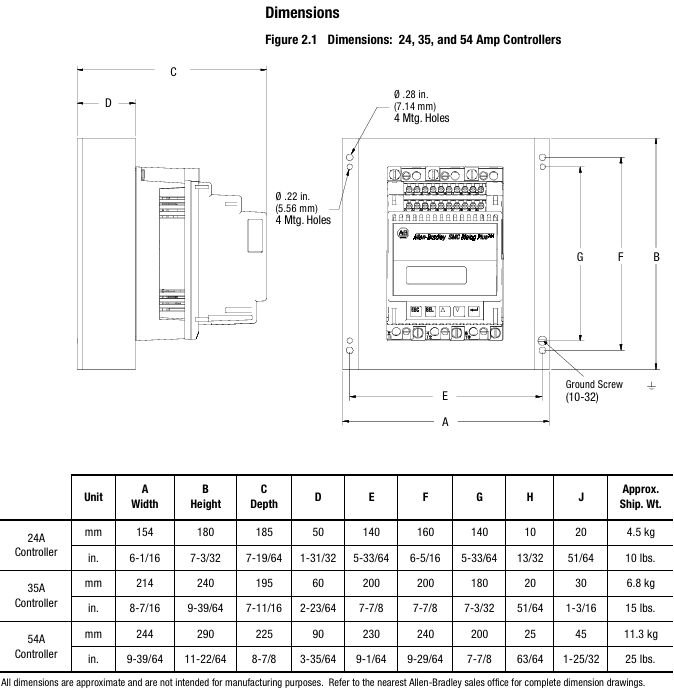

Heat dissipation and casing

The controller is of an open design and needs to be installed inside a metal casing. The temperature inside the casing should be maintained between 0 ° C and 50 ° C. The heat dissipation power of controllers with different current levels varies (such as 110W for 24A and 2760W for 1000A), and sufficient ventilation openings should be reserved in the ventilation casing (such as 65cm ² openings for 24-54A). Some models (97A and above) come with their own cooling fans, and the fan power supply needs to be wired separately.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands