Triconex 3624 Digital Output Module

Tricon controller: It adopts the third mock examination redundancy (TMR) architecture to achieve fault tolerance, integrates three independent parallel control systems and comprehensive diagnostic functions, ensures no single point of failure through the "three out of two" voting mechanism, and achieves high integrity, error free, and uninterrupted process operation.

TMR architecture details: Three identical channels independently and parallelly execute control programs, digital I/O is verified through dedicated software and hardware voting, and analog input adopts median selection; The channels are isolated from each other, and a single channel failure does not affect other channels. The faulty module can be replaced online.

Triconex 3624 Digital Output Module

Overview of the Core of Tricon Fault Tolerant Control System

Core Definition and Architecture

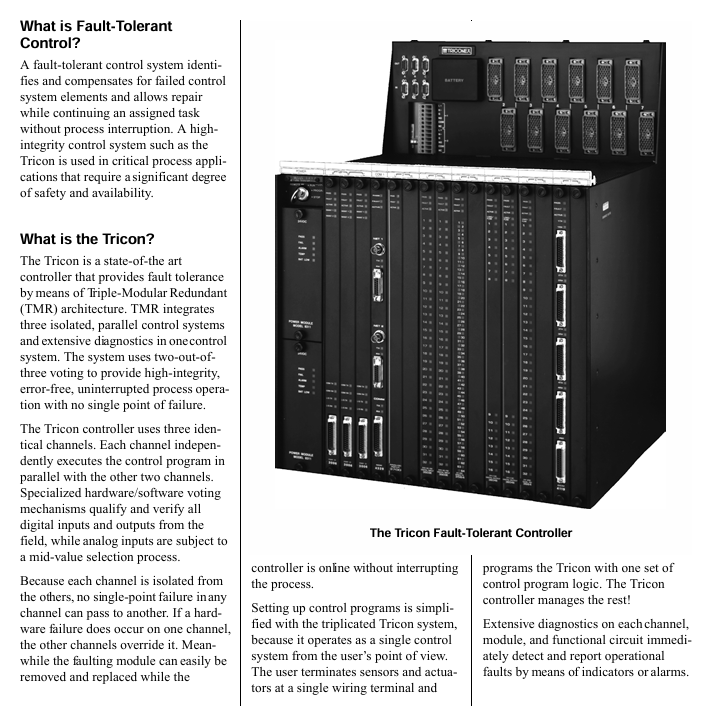

Fault Tolerant Control: capable of identifying and compensating for faulty control units, allowing for repairs without interrupting processes, suitable for critical process applications that require high safety and availability.

Tricon controller: It adopts the third mock examination redundancy (TMR) architecture to achieve fault tolerance, integrates three independent parallel control systems and comprehensive diagnostic functions, ensures no single point of failure through the "three out of two" voting mechanism, and achieves high integrity, error free, and uninterrupted process operation.

TMR architecture details: Three identical channels independently and parallelly execute control programs, digital I/O is verified through dedicated software and hardware voting, and analog input adopts median selection; The channels are isolated from each other, and a single channel failure does not affect other channels. The faulty module can be replaced online.

Key Features

No single point of failure; Support 3, 2, or 1 main processor to run until shutdown; Fully implemented and transparent triple transformation; Comprehensive system diagnosis; Complete I/O module series; Provide dual I/O and single I/O modules for safety critical and limited availability requirements; Remote I/O can be up to 7.5 miles (12 kilometers) away from the main processor; Support simple online module maintenance; Has extremely high reliability and availability.

Typical application scenarios

Emergency Safety Shutdown (ESD): protects key units such as refineries and petrochemical/chemical plants, monitors parameters such as pressure and feed rate, avoids false tripping of traditional relay systems, has sensor integrity detection, integrated shutdown and control functions, and can be connected to monitoring data highways.

Boiler flame safety: Integrating boiler protection, start stop safety interlock, and flame safety functions, replacing traditional discrete components, improving resource utilization, and maintaining or exceeding the safety of electromechanical protection systems.

Turbine control system: realizes the control and protection of gas/steam turbines, integrates speed control and start stop sequence, avoids unplanned shutdowns through I/O module hot standby, and automatically activates the standby module in case of faults.

Marine fire and gas protection: supports online replacement of faulty modules, built-in diagnostic management module, wiring and sensor faults, simulated fire and gas detectors can be directly connected, replacing traditional fire and gas panels, saving space and ensuring high safety and availability.

Detailed specifications of 3624 digital output module

Module basic information

Type: TMR (the third mock examination redundancy), with supervised function.

Nominal voltage: 24 VDC.

Output points: 16 points, shared.

Electrical parameters

Voltage range: 16-30 VDC, maximum voltage 36 VDC.

Voltage drop: Typical value<1.5 VDC.

Power module load:<10 watts.

Current rating: maximum 0.7 A per point, maximum surge current of 4.8 A within 10 ms.

Minimum required load: 30 mA.

Load leakage current: maximum 4 mA.

Point isolation: minimum 1500 VDC.

Fuse: None (self-protection).

Function and Diagnosis

Monitoring function: By using voltage and current loop circuits, combined with online diagnosis, the output switch, on-site circuit, and load status can be verified, and faults such as on-site power loss/fuse melting, load open circuit/loss, load misoperation short circuit, load power-off short circuit, etc. can be detected; The POWER alarm is activated when the on-site voltage cannot be detected, and the LOAD alarm is activated when the load cannot be detected.

Module status diagnosis: equipped with PASS (module passes self-test), FAILT (module fault), ACTION (module activation) indicator lights, with ON/OFF status indicator lights at each point, color code Turquoise Green.

Compatibility and Installation

Supporting hot standby modules requires a separate external terminal panel (ETP) and cable interface with the Tricon backplane; The module adopts a mechanical key control design to prevent accidental installation into the wrong slot; On site wiring requires connecting the on-site power supply to each output point of the on-site terminal, with the output designed to provide current to the on-site equipment.

System configuration and hardware components

System Composition

Composed of one main chassis and up to 14 extended or remote extended (RXM) chassis, up to 15 chassis can support 118 I/O modules and communication modules, and can connect OPC clients, Modbus devices, other Tricon controllers, Ethernet (802.3) external host applications, and Foxboro, Honeywell DCS.

Chassis Layout and Configuration Rules

Main Chassis: There are two power modules on the left side and three main processors on the right side. The remaining space is divided into six logical slots for I/O and communication modules, as well as one COM slot without a hot spare position. Each logical slot contains two physical spaces (active module and optional hot spare module); Address 1 requires three 3008 model main processors (Tricon v9.6 and above) and two power modules.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands