Yokogawa 701944/701945 100:1 High Voltage Probe

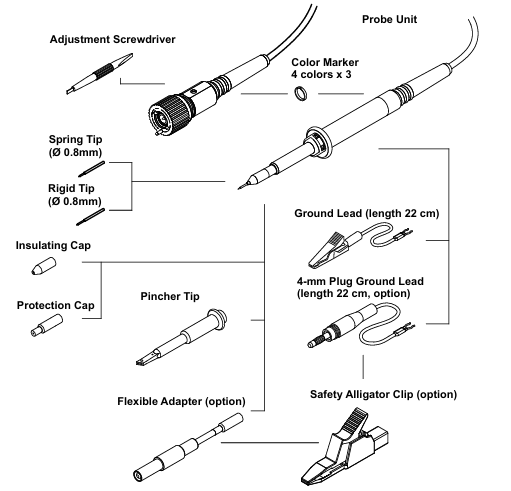

Replacement accessory set: Two sets are available, "Accessories Basic" (B9852HK) including 2 spring tips, 2 rigid tips, 2 clamp tips, and 2 grounding wires; The "Accessories HV" (B9852HL) includes one flexible adapter, one 4mm plug grounding wire, and two safety crocodile clips, making it easy to replace accessories in bulk after wear and tear.

Operation process

(1) Basic Connection

Connection between probe and oscilloscope: Connect the BNC connector of the probe to the 1M Ω input port of the oscilloscope, ensuring that the input impedance of the oscilloscope is set to 1M Ω; the probe ID pin will be automatically recognized by the oscilloscope, and the attenuation ratio will be automatically set to 10:1. If it is not automatically set, it needs to be manually adjusted to the corresponding gear to ensure accurate measurement data.

Grounding connection: Connect the probe grounding wire to the grounding potential, which can only be used for grounding connection and cannot be used for other purposes; It is strictly prohibited to use non designated grounding wires to prevent measurement errors or safety risks caused by poor grounding.

(2) Calibration process

Low frequency compensation (LF Compensation): Connect the probe input to the probe compensation adjustment terminal (CAL/COMP terminal) of the oscilloscope, use the matching adjustment tool to rotate the low-frequency compensation micro adjuster, adjust the observed waveform to a standard square wave, ensure that the probe capacitance matches the oscilloscope input capacitance, and ensure measurement accuracy within the frequency range from DC to the upper limit of the bandwidth. Compensating for abnormalities (under compensation/over compensation) will cause waveform distortion and require readjustment.

HF Compensation: Calibration has been completed before leaving the factory. If adjustment is needed, a signal generator that can generate a fast rising edge rectangular wave needs to be connected. Slide the probe housing to expose the high-frequency compensation micro adjuster, and use an adjustment tool to smooth the rising edge to ensure the accuracy of high-frequency signal measurement.

DC Adjustment: Before leaving the factory, a measuring instrument with a 500VDC voltage source and a 1M Ω± 0.01% input impedance is used for calibration. Users do not need to make routine adjustments. If high-precision measurement is required, they can contact the dealer for professional calibration.

(3) Precautions for using the probe

Tip replacement: When replacing the contact tip, it is necessary to clamp the tip with pliers and pull it out vertically along the axis of the probe. It is strictly prohibited to clamp the white plastic insulator or housing (to avoid damaging the probe); When inserting the new tip, align it with the socket along the axis and gently press it until it fully fits, ensuring good contact.

Cable protection: To prevent the probe body from being impacted, excessive bending or pulling of the cable is not allowed to prevent damage or breakage of internal circuits, which may affect signal transmission.

Voltage derating: When the input signal frequency increases, the maximum input voltage of the probe will decrease. It is necessary to refer to the "Voltage derating curve" to select the appropriate input voltage to avoid overvoltage damage to the probe; Pulse measurement must comply with the corresponding limitations of peak pulse voltage, duty cycle, and duration to ensure safe use.

Maintenance and disposal

(1) Daily maintenance

Cleaning: When cleaning the probe housing, only a soft cloth dipped in water or isopropanol can be used to wipe it. After wiping, it must be completely dry before it can be used for measurement. Volatile chemicals such as benzene and diluents should not be used to prevent corrosion or deformation of the housing.

Accessory inspection: Regularly check whether the probe tip, grounding wire, and cable are intact. If the tip is worn, the cable is cracked, or the grounding wire is aged, the corresponding accessories should be replaced in a timely manner to avoid affecting measurement accuracy or causing safety hazards.

(2) Disposal of waste

When discarding probes or accessories, it is necessary to comply with the laws and regulations of the country/region where they are located and not to dispose of them at will; Components belonging to electronic waste, such as probe bodies and cables, must be disposed of in accordance with local electronic waste disposal regulations to avoid environmental pollution and comply with the EU WEEE Directive and relevant environmental requirements of each country.

Technical parameters

(1) Electrical parameters

Parameter 701944 701945 Remarks

Attenuation ratio 100:1 ± 2% (DC) 100:1 ± 2% (DC) requires the connection of an oscilloscope with an input impedance of 1M Ω± 1%

The typical value of voltage coefficient is 0.0005%/V, which reflects the influence of voltage changes on the attenuation ratio. The smaller the coefficient, the higher the accuracy

When the system bandwidth is -3dB, an oscilloscope with a bandwidth ≥ 500MHz needs to be connected to 400MHz and 250MHz, otherwise it is limited by the oscilloscope bandwidth

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands