Yokogawa AQ6375E Spectral Analyzer Remote Control

Yokogawa AQ6375E Spectral Analyzer Remote Control

Overview

This document is the remote control user manual for Yokogawa AQ6375E spectrometer (2nd edition, released in February 2024), focusing on the GP-IB and Ethernet communication interface functions of the core equipment. It provides detailed guidance for users to complete interface configuration, remote control programming, status monitoring, and automated measurement program writing. At the same time, it provides a complete document system, technical support channels, and version revision records to ensure that users can safely and efficiently achieve spectral measurement tasks through remote control.

Safety regulations and symbol explanations

(1) Warning symbols and their meanings

The manual adopts a three-level warning system and provides French reference to ensure clear safety guidance in multilingual scenarios

Warning: Operations that may cause serious or fatal injuries, such as "operating high-voltage circuits without grounding" and "using equipment in flammable environments", must strictly follow preventive measures.

CAUTION: Indicates operations that may cause minor injury or equipment/data damage, such as "wet hand plugging and unplugging communication cables" or "loose cable connections leading to measurement errors".

Note: Key information indicating the correct operation of the device, such as "Communication interfaces cannot be used simultaneously" and "Command execution sequence requirements".

Equipment symbol: The "manual reference required" symbol marked on the equipment indicates that the operation needs to refer to the manual for special guidance (such as interface parameter configuration).

(2) Core Security Guidelines

Scope of use: Only for spectral measurement (such as wavelength, power, signal-to-noise ratio analysis), strictly prohibited from using beyond the range; Measurement category II in accordance with IEC 61010-031 standard cannot be used for category III/IV scenarios (such as high-voltage grid measurement).

Grounding requirements: The protective grounding terminal of the equipment must be reliably grounded, and the probe grounding wire must be connected to the grounding potential. Double grounding can effectively prevent the risk of electric shock.

Environmental restrictions:

Working environment: temperature 0~50 ℃, humidity 20%~80% RH (non condensing);

Storage environment: temperature -40~71 ℃, humidity 20%~80% RH (non condensing);

It is strictly prohibited to use in damp, dusty, flammable/explosive gas environments. The working altitude should not exceed 2000m, and the storage altitude should not exceed 15000m.

Equipment status: If any signs of damage such as damaged interface cables or exposed metal are found, immediately stop using and contact the dealer for repair; It is strictly prohibited to disassemble or modify communication interface components. Yokogawa shall not be held responsible for any malfunctions caused by unauthorized modifications.

Remote communication interface function and configuration

AQ6375E supports two remote interfaces, GP-IB and Ethernet, which cannot be used simultaneously. When one interface is enabled, the other will be automatically disabled.

(1) GP-IB interface (IEEE 488.2 standard)

1. Core features and parameters

Function: Supports remote reception of device setting instructions, acquisition of measurement data (such as spectral waveforms, analysis results) and status information, compatible with SCPI standard commands and AQ6317 legacy commands.

Technical Specifications:

Interface type: 24 pin GP-IB connector, compliant with IEEE 488-1978 electromechanical specifications;

Communication protocol: Following the IEEE 488.2-1992 functional specification, supporting SH1 (source handshake), AH1 (receive handshake), T6 (talker function), L4 (listener function);

Address range: 0~30 (needs to be set through the device menu and cannot be duplicated with other devices in the bus);

Cable requirements: Use GP-IB cables that comply with IEEE standards, with a single segment length of ≤ 2m and a total length of ≤ 20m.

2. Connection and configuration process

Hardware connection:

Turn off the device and PC power, and connect the GP-IB port of the Rear panel of the device to the GP-IB card of the PC using a GP-IB cable;

Tighten the screws of the cable connector to ensure reliable contact; When connecting multiple devices, use a "daisy chain" or "star" topology and prohibit circular connections.

Parameter settings:

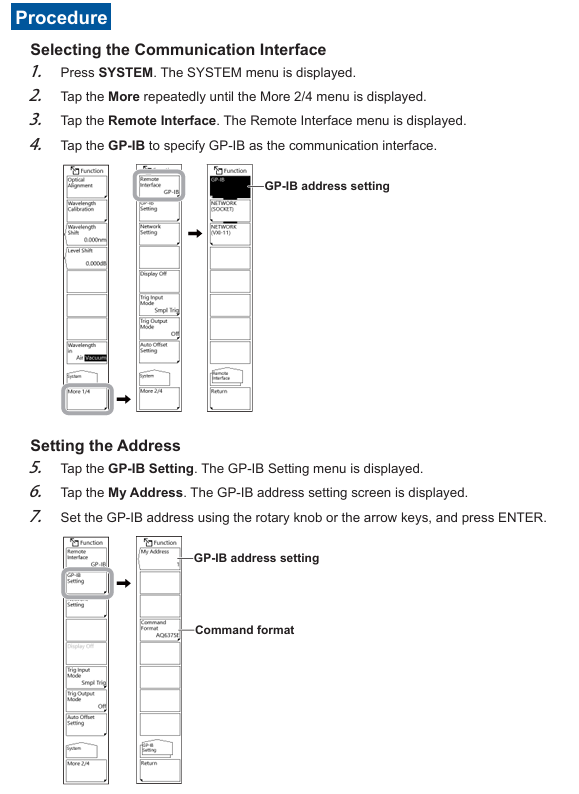

Press the SYSTEM button on the device to enter the "More 2/4" menu, select "Remote Interface" → "GP-IB";

Go to "GP-IB Setting" → "My Address", set the address (0-30) using the knob or directional keys, and press ENTER to confirm;

If you need to use AQ6317 compatible commands, go to "Command Format" and select "AQ6317" (default "AQ6375E").

3. Remote/Local Mode Switching

Switch to remote: The PC sends a REN (Remote Enable) signal and sets ATN to "True". The device enters remote mode, and the top of the screen displays "Remote". Only the LOCAL key can be operated (used to release remote).

Switch to local: Press the LOCAL button on the device, or send the GTL (Go To Local) command from the PC; If the PC sends the LLO (Local Lock Out) command, the LOCAL key will be disabled and must be unlocked by setting REN to "False" on the PC.

(2) Ethernet interface (TCP/IP protocol)

1. Core features and parameters

Function: Consistent with GP-IB function, supports remote command reception, data transmission, and status monitoring, and supports Socket and VXI-11 communication modes.

Technical Specifications:

Interface type: 1 RJ45 port, compliant with IEEE 802.3 standard;

Transmission rate: 10/100/1000 Mbps (adaptive);

Port number: default 10001/tcp (Socket mode), VXI-11 mode does not require manual setting;

Compatibility: Supports IPv4/IPv6, only compatible with Windows 8.1/10/11 system PCs (requires installation of Yokogawa USB driver YKMUSB and communication library TMCTL).

2. Connection and configuration process

Hardware connection:

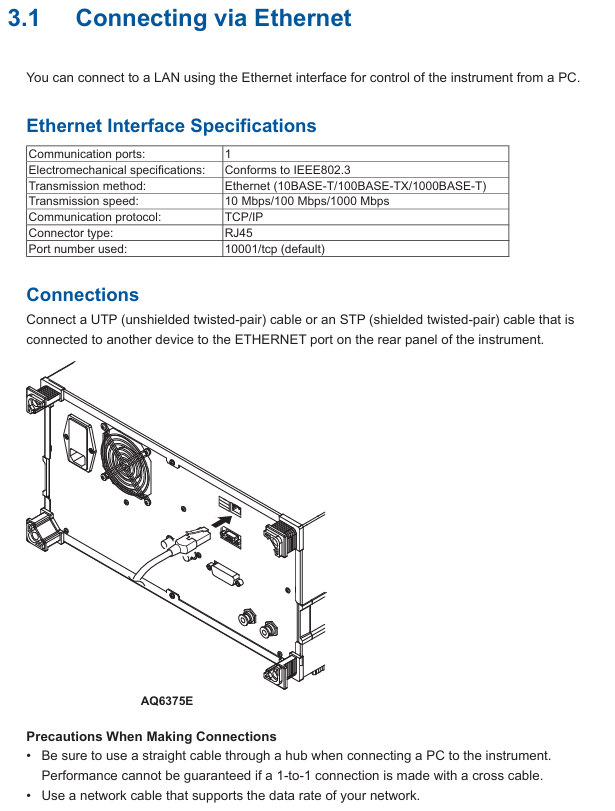

Connect the Ethernet port of the Rear panel to the hub/router (and then connect to the PC) using UTP/STP Ethernet cables;

It is prohibited to use cross cables to directly connect PCs and devices. It is recommended to use a hub connection to ensure stability.

Parameter settings:

Press the SYSTEM key to enter "More 2/4" → "Remote Interface", select "WORK (SOCKET)" or "WORK (VXI-11)";

Go to "Network Setting" → "TCP/IP Setting":

IPv4: Select "AUTO (DHCP)" to automatically obtain the address, or manually set the IP address, subnet mask, and default gateway with "MANUAL";

IPv6: Similarly, automatic or manual configuration can be selected;

Socket mode requires additional settings for "Remote Port No." (default 10001) and "Remote User Account" (default username "anonymous", no password required).

3. Remote authentication and connection (Socket mode)

Certification process:

PC sends OPEN "username" command (such as OPEN "anonymous");

The device returns' Authoricate CRAM-MD5 ', and the PC sends the password (anonymous users can ignore it);

The device returns "READY", authentication is successful, and remote mode is activated (the screen displays "Remote").

Disconnect: The PC sends the CLOSE command and the device switches to local mode.

Fundamentals of Programming and Instruction System

(1) Core Programming Concepts

1. Message format

Program message (PC → device): composed of one or more instruction units, separated by semicolons ";", and ending with a termination symbol (LF, ^ END, or LF+^ END); The format is "program header+space+program data", for example: SENSe: WAVelocity: CENTer 1550NM; SPAN 10NM (with a center wavelength of 1550nm and a span of 10nm).

Response message (device → PC): corresponds to the query instruction in the program message, in the format of "response header+space+response data", and ends with LF+^ END; If there are multiple queries, the response will be returned in the order of the queries, for example: * IDN? The response is YOKOGAWA, AQ6375E, 123456789,1.00 (manufacturer, model, serial number, firmware version).

2. Data type

Supporting multiple data formats to adapt to different control requirements, the key types and descriptions are as follows:

Example of Data Type Format Explanation

Decimal numbers (<Decimal>) contain integers (NR1), fixed-point numbers (NR2), and floating-point numbers (NR3). The device receives any format and responds uniformly using NR3 to set the sampling rate: TIMebase: SRATE 1E6

Physical quantities (such as<Voltage>/<Time>) are numerical values prefixed with units or multiples, and units/prefixes are not case sensitive. Time axis setting: TIMebase: TDIV 1US

Register supports decimal, hexadecimal (# H), octal (# Q), and binary (# B), and responds uniformly by setting events in decimal. Enable: STATus: EESE # H01

Pre defined mnemonic for character data (<Character data>), to be selected from options, case insensitive setting coupling method: CHANnel1: COUPling AC

Boolean value (<Boolean>) supports ON/OFF or numerical values (0=OFF, non-zero=ON), and the response is uniformly 0/1 to open the channel display: CHANnel1: DISPlay ON

The string (<String data>) needs to be enclosed in single/double quotation marks, and if it contains quotation marks, two consecutive setting labels need to be entered: CHANnel1: LABel "CH1_TEST"

Block data (<Block data>) is 8-bit binary data in the format of "# N+N bit data length+data byte sequence", only used to respond to waveform data. Response: # 800000010ABCDEFGHIJ

(2) Core Instruction Group

The manual divides instructions into 17 command groups, covering full functions such as device acquisition, analysis, display, and storage. The core command groups and functions are as follows:

Command Group Core Instruction Function Description

ABORt Group: ABORt stops measuring, calibrating, and other ongoing operations (such as scanning initiated by Initiatiate)

CALCulate Group :CALCulate:CATegory、:CALCulate:DATA? Select analysis type (such as spectral width, WDM analysis), query analysis results

SENSe Group: SENSe: WAVelocity: CENTer, SENSe: BANDWidth Set measurement conditions (center wavelength, resolution bandwidth), query measurement parameters

TRACe Group :TRACe:ACTive、:TRACe[:DATA]:Y? Set active trace and query wavelength/level data of trace

MMEMory Group: MMEMory: STORe: TRACe, MMEMory: LOAD: SETTing Store trace data, load device settings files

SYSTem Group :SYSTem:ERRor? 、 SYSTem: COMMunicate: Conform Query Error Queue, Switch Command Format (compatible with AQ6375E/AQ6317)

Common Command Group *IDN? 、 *RST, OPC standard IEEE 488.2 command, query device information, reset device, mark operation completed

Example: Programming process for basic spectral measurement

Initialize device: * RST (reset to default state);

Set measurement conditions: SENSe: WAVelocity: CENTer 1550NM; SPAN 10NM (center wavelength 1550nm, span 10nm), SENSe: BANDWidth 0.1NM (resolution 0.1nm);

Start scan: Initiatate: SMODe SINGle; Initiatate (single scan mode and start);

Query scan status: Status: Operation: EVENT? (Waiting for scanning to complete);

Execution analysis: CALCulate: CATego SWTHresh; CALCulate (THREE method spectral width analysis);

Get result: CALCulate: DATA? (Query and analysis results);

Storage data: MMEMory: STORe: TRACe TRA, CSV, "data1. csv", INT (store trace TRA in CSV format to internal memory).

Status monitoring and troubleshooting

(1) Status reporting mechanism

The device achieves status monitoring through status registers and queues, with core components including:

Status Byte Register (STB): 8-bit binary data that reflects the overall status of the device (e.g. bit7=operation status summary, bit5=standard event summary, bit4=data in output buffer), can be accessed through * STB? Search.

Standard Event Register (ESR): records device standard events (such as operation completion, command errors), which can be enabled through * ESE settings, * ESR? Query and clear.

Operation status register: records the execution status of measurement, calibration, and other operations (such as scanning, calibration completed), through: STATus: OPERation: EVENT? Search.

Error queue: stores the latest error code and description, via SYSTem: ERRor? Query and clear (e.g. error code 300=parameter out of range, 320=undefined variable).

(2) Common problem solving

Troubleshooting steps for problem types and phenomena

Communication connection failure: GP-IB/Ethernet cannot establish connection. 1. Check if the cable connection is secure and confirm that the Ethernet IP address is in the same network segment; 2. GP-IB confirms that the address is not conflicting, and Ethernet confirms that the port number is correct; 3. Restart the device and PC and try again

Instruction execution is unresponsive. After sending the instruction, there is no feedback or error message from the device. 1. Check the syntax of the instruction (such as case and parameter range), refer to Chapter 5 of the manual to confirm the format; 2. Confirm that the device is in remote mode and there is no local lock; 3. Extend the communication timeout (recommended ≥ 30 seconds to avoid automatic offset calibration causing timeout)

1. Confirm that the data format (ASCII/binary) is consistent with the device settings, and that waveform data is missing or has abnormal values due to data transmission distortion; 2. Ethernet checks network bandwidth to avoid transmitting large amounts of data simultaneously; 3. Re execute scanning or calibration to ensure the validity of measurement data

Program Function (Automated Measurement)

(1) Core competencies

Support writing custom programs to achieve full process automation of measurement condition setting, automatic scanning, data analysis, and data storage, without the need for external controller intervention. The program can be stored in the device's internal memory or USB storage medium, supporting 1-100 program numbers.

(2) Program Editing and Execution

Editing process:

Press the APP button, select "Program" ->"Program Edit", and enter the program editing interface;

Select function commands (such as scan settings, analysis start) or special commands (such as loop, delay) through "Command Select", set parameters, and generate program lines;

Supports inserting, copying, and deleting program lines, with a maximum program line count of 200.

Execution process:

Select the target program from the program list and click "Execute" to start it;

During the execution process, real-time output (such as measurement results and status information) can be viewed through the "Output Window", which supports pausing (PAUSE command) or terminating (ABORT command).

(3) Example program: Periodic spectral measurement

plaintext

001 *RST ; Reset device

002 :SENSe:WAVelength:CENTer 1550NM ; Set the center wavelength to 1550nm

003 :SENSe:SPAN 10NM ; Set span to 10nm

004 :SENSe:BANDwidth 0.1NM ; Set resolution to 0.1nm

005 N=5 ; Cycle 5 times

006 :INITiate:SMODe SINGle; :INITiate ; single scan

007 :CALCulate:CATegory SWTHresh ; Choose the THREE method for spectral width analysis

008 :CALCulate ; execution analysis

009 :CALCulate:DATA? ; Query and analyze results

010 :MMEMory:STORe:DATA "result.csv",INT ; Store results in internal memory

011 WAIT 10S ; Delay for 10 seconds

012 N=N-1; IF N<>0 GOTO 006 ; Loop until N=0

013 END ; Program ends

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands