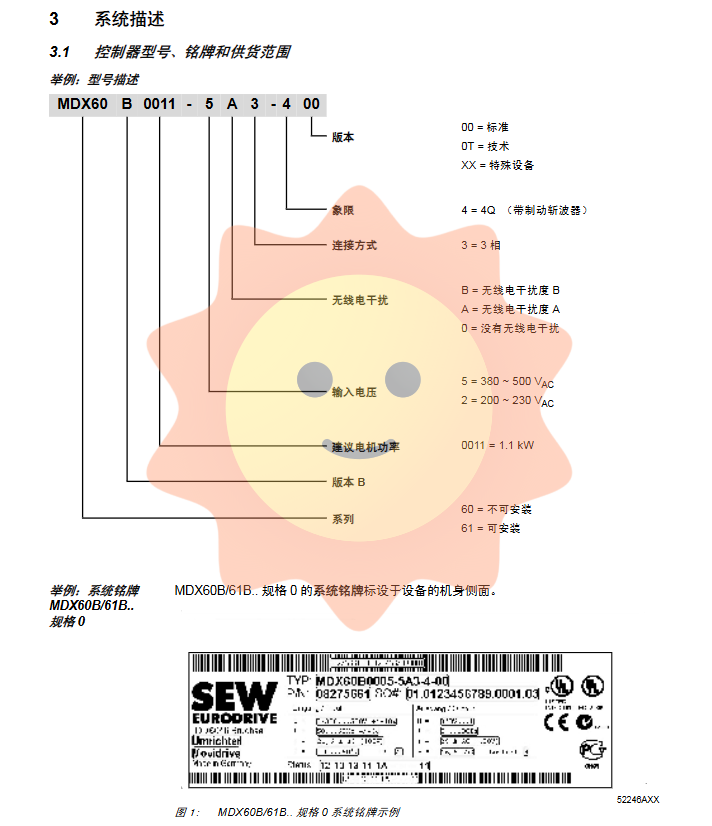

SEW MOVIDRIVE ® MDX60B/61B Inverter: Installation, Debugging, and Maintenance Guide

Chapter 3: Professional Installation - The Foundation for Ensuring Stable Operation

Correct installation is the guarantee for long-term stable operation of equipment, involving mechanical fixation, electrical connection, and EMC compatibility.

Key points for mechanical installation:

Installation position and gap: It must be installed vertically, with at least 100mm of heat dissipation space reserved above and below, and can be installed side by side. The large-sized equipment (specification 6) is equipped with lifting lugs and load-bearing rods.

Tightening torque: It is necessary to strictly follow the torque requirements of different specifications of terminals (power terminal 0.6 Nm to 20 Nm, control terminal 0.6 Nm) and use original components.

Protective cover: Some specifications provide protective covers, which can increase the protection level after installation (such as specification 2S up to IP20).

Electrical connection specifications:

Cable selection: The cross-sectional area of power and motor wires should be selected according to the rated current. It is recommended to use 0.20-2.5 mm ² single core or 0.25-1 mm ² double core shielded wire for control signal lines.

Grounding and shielding:

Reliable protective grounding (PE) must be ensured.

All cables (except for power supply incoming lines) should use shielded wires, and the shielding layer should be grounded with a large area and low impedance through shielding clamps at the frequency converter end, and the motor end should also be grounded. To avoid forming a grounding loop, it is possible to consider grounding the single end through a Y capacitor.

Strong and weak electrical cables must be laid separately in different cable trays.

Braking resistor connection:

Twisted shielded cables must be used. Except for specific models, external bimetallic relays (F16) or integrated temperature switches (BW... - T type) must be configured for overheating protection.

Warning: When the braking resistor is working, there is high temperature and high DC voltage (about 900V) on its surface and connecting wires. The installation position should be carefully selected (usually located on the top of the cabinet).

EMC compatibility measures:

To meet the Class B radiation limit of EN 61800-3, output reactors (HD...) or output filters (HF...) can be selected, and power filters (NF...) can be installed correctly (close to the frequency converter, with a connection wire shorter than 400mm).

In IT power grid (neutral point ungrounded), insulation monitoring equipment needs to use pulse measurement method, and the effect of power filter will be limited.

Chapter 4: System Debugging - From Parameter Setting to Motor Startup

Debugging is a key step in matching the frequency converter with specific motors and loads.

preparation:

Check the mechanical and electrical installation.

Ensure safety and prevent accidental start-up (such as unplugging X13 plug).

Connection debugging tool: Insert the DBG60B operation panel, or connect with MOVITOOLS installed through UWS21A (RS232) or USB11A converter ® PC with V4.0 or above.

Connect the main power supply and 24V control power supply.

Debugging VFC mode using DBG60B control panel:

Language selection: After powering on, first select the operating interface language.

Enter the debugging wizard: Select "STARTUP PARAMET" from the context menu and choose the parameter group (1 or 2).

Enter key data:

Operation mode selection (such as VFC1).

Motor type (SEW motor or non SEW motor).

Motor nameplate data: rated voltage, rated frequency, connection method. For non SEW motors, it is also necessary to input rated current, power, power factor, and rated speed.

Rated voltage of the main power supply.

TF/TH sensor response settings.

Perform calculation and save: After confirming the data, start automatic calculation, and save the parameters to the frequency converter EEPROM after success.

Speed control debugging (VFC-n-CON): Based on the above, additional settings such as encoder type and resolution, system stiffness, load inertia, and minimum ramp time are required.

Using MOVITOOLS ® Software debugging:

This software provides graphical guides and supports debugging of all operating modes (VFC, CFC, SERVO), with more comprehensive functions, especially suitable for complex applications and IPOSplus ® Programming.

Motor starting method:

Simulation Given: Input analog voltage/current signals through terminal X11 (AI1), and control start stop and speed with binary inputs (enable, direction, quick stop) on X13.

Fixed Given: By combining multiple binary input signals of X13, select fixed speed values (n11, n12, n13, etc.) stored internally.

Manual operation: Control the motor start stop, steering, and speed directly through the DBG60B control panel for easy on-site testing.

VFC&Flying Start: Used for smooth cutting in of rotating motors, requiring precise setting of current compensation parameters (P322).

Chapter 5: Operation Monitoring and Intelligent Maintenance

The device provides rich status display and diagnostic functions.

Running display:

7-segment digital display: displays running status codes (such as "0" not ready, "4" VFC running, "F" fault) and fault/warning codes.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands