Powell PowlVac ® CDR&GCB Series 4 Vacuum Circuit Breaker

Post fault maintenance: After interrupting the short-circuit current near the rated value, it is necessary to immediately check the arc extinguishing chamber, contacts, and mechanical components.

Preparation before maintenance: Return the equipment to the "test/disconnect" position, disconnect all power sources and ground, and record the reading of the operation counter.

(2) Core maintenance project

Cleaning and Inspection:

Use a vacuum cleaner or dry cloth to remove dust, and prohibit the use of compressed air (to prevent dust from entering the bearings); Insulated components (such as arc extinguishing chamber supports and operating push rods) should be wiped with isopropanol, and the use of detergents is prohibited.

Check if the fasteners are loose, if the contacts are burned, if the energy storage mechanism components are worn, and if damaged parts need to be replaced in a timely manner.

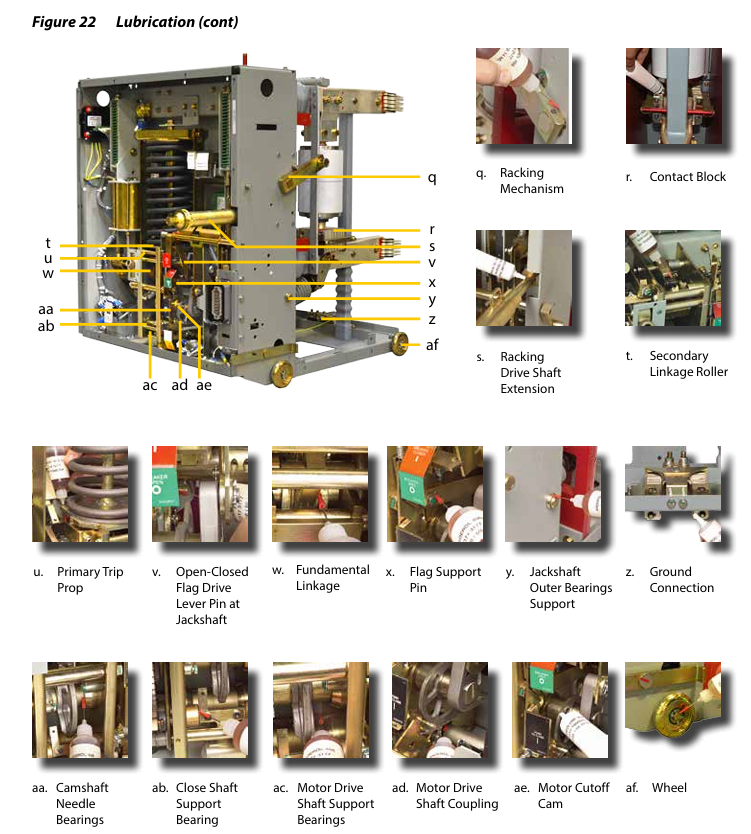

Institutional lubrication (using Powlube-104 kit)

A - Lubricating grease: Apply to moving parts such as camshaft bearings and closing lock shaft surfaces, thin coat and remove excess grease.

B - Lubricating grease: used for one-time disconnection contacts, grounding connection contacts, and other conductive contact surfaces to ensure good contact.

C - Lubricating oil: Drip onto bearings such as ratchet gears, connecting rod shafts, and rack and pinion transmission mechanisms, penetrating into the mating surfaces.

Maintenance of vacuum arc extinguishing chamber

Contact wear inspection: Measure the gap between the operating push rod lock nut and the spring yoke in the closed state. When the gap reaches the "end of life value" marked on the nameplate, the arc extinguishing chamber needs to be replaced.

Vacuum integrity retest: Repeat the vacuum test annually or during maintenance to ensure no leaks.

Institutional adjustment (only after major repairs)

Ratchet holding claw adjustment: By adjusting with eccentric bolts, ensure that the ratchet operates without any "knocking sound" and that manual/electric energy storage is smooth.

Adjustment of the opening system: Adjust the gap between the main opening support rod (0.005 "-0.015") to ensure reliable opening action. Do not trip when tested with a 0.090 "plug gauge, and trip when tested with a 0.030" plug gauge.

Lock check switch adjustment: Insert a 0.045 "plug gauge and adjust the switch position until the contacts are closed, ensuring that the switch is disconnected when opening and closed when resetting.

(3) Optional testing items

**Timing test * *: Closing time ≤ 80ms (coil energized to arc extinguishing chamber contact), opening time<35ms (3 cycles)/<55ms (5 cycles).

Main circuit resistance test: Measure the voltage drop with 100A DC and calculate the resistance value, which should comply with the limit values in the table (such as 15PV36CDR 3000A model ≤ 40 μ Ω).

Spare parts replacement and ordering

(1) Spare parts ordering requirements

Provide complete nameplate information: model, serial number, rated voltage/current/short-circuit current, control voltage.

Clearly describe the spare parts (such as "vacuum arc extinguishing chamber components"), quantity, and if referring to the illustrations in the manual, indicate the location of the components.

(2) Key spare parts and replacement process

Spare part name applicable scenario replacement precautions

The contact wear of the vacuum arc extinguishing chamber component exceeds its service life and the vacuum leakage is 25kA-50kA. The model can be replaced on site (refer to manual 01.4SM.1900); The 63kA model requires professional personnel to operate and Powell needs to be contacted

Sliding contact assembly (≤ 50kA) with contact erosion and exposed copper substrate can be disassembled and reversed for use (only the upper end is worn). After replacement, apply B-grease and bolt torque of 8-12 ft-lb

When the closing/opening coil burns out or fails to operate, the control power supply needs to be disconnected to ensure that the coil voltage is consistent with the prototype number (such as 24VDC/120VAC)

The charging motor does not rotate and energy storage fails. Refer to manual 01.4SM.1200 for reference. After replacement, test the motor direction and energy storage efficiency

Poor grounding of grounding connection components and oxidation of contacts. When disassembling, it is necessary to raise the equipment and apply B-lubricating grease after replacement to ensure reliable grounding

(3) Recommended spare parts list

It is recommended to reserve 1 set of spare parts for every 10 circuit breakers:

Vacuum arc extinguishing chamber (corresponding model), sliding contact assembly, closing/opening coil, charging motor, anti pump relay, locking inspection switch, lubrication kit (Powlube-104).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands