Powell PowlVac ® CDR&GCB Series 4 Vacuum Circuit Breaker

Interlocking protection: Transmission is prohibited in the closed state; The secondary plug can only be unplugged in the "test/disconnect" position; When in the middle position, trigger the "free release" and prohibit closing.

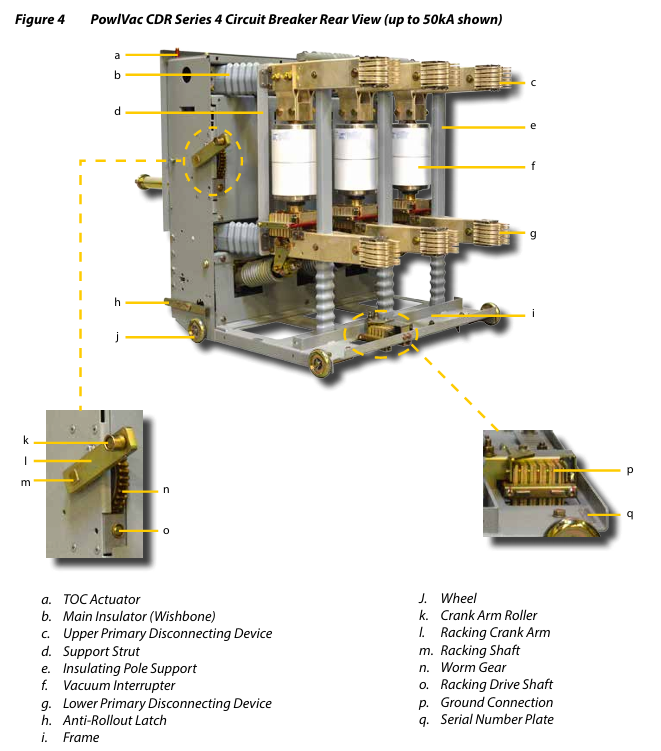

Vacuum Interrupters

Core function: To achieve arc free breaking of the main circuit through a vacuum environment, different rated currents (25kA-63kA) correspond to different internal structures, and external support needs to be fixed through insulation.

Connection method:

25kA/36kA/50kA models: The arc extinguishing chamber is connected to the primary disconnect device through copper contact blocks, and the sliding contact components achieve multi-path current transmission.

63kA model: connected by copper castings, with built-in multi contact strips to reduce current density.

Switchgear interface components

One time disconnection device: 6 (2 per phase), connected to the fixed end of the cabinet to transmit the main circuit current.

Secondary disconnection device: located in the lower right corner of the equipment, it controls the transmission of power and signals through a plug, and can only be plugged and unplugged in the "test/disconnect" position.

Grounding connection: Spring loaded grounding contact, automatically grounded after insertion into the cabinet, ensuring reliable grounding at all positions.

Anti slip lock: To prevent the circuit breaker from accidentally slipping out of the cabinet, it needs to be manually pressed to unlock before it can be pulled out.

Installation process and operating specifications

(1) Reception and Storage

Receiving inspection: After unpacking, check whether the appearance of the equipment is damaged, and verify that the nameplate information (model, rated value, serial number) is consistent with the order; If there is any damage, immediately file a claim with the transportation company and notify Powell.

Storage requirements:

Indoor storage: temperature between 1 ° C and 60 ° C, humidity ≤ 60% (no condensation), space heater (if equipped) needs to be turned on, or desiccant needs to be placed.

Outdoor storage (outdoor only): Temporary protective covers are required to prevent pollutants from entering, and the temperature should be controlled above freezing point.

(2) Pre installation testing

Before the equipment is put into use, it needs to be tested in the following order to ensure its performance is qualified:

High voltage insulation integrity test:

Use a 2500V insulation resistance meter to measure phase to phase and phase to ground insulation, and record the values (no fixed qualified values, need to track trends).

AC voltage withstand test: According to ANSI C37.20.2 standard, the test voltage for 5kV equipment is 14.25kVAC, and for 15kV equipment it is 27kVAC, with no breakdown for 1 minute; After testing, it is necessary to ground and discharge for at least 1 minute to avoid residual charges causing electric shock.

Vacuum integrity test:

Recommended communication test: Apply 25kVAC in the open state for 10 seconds without breakdown.

DC test (optional): Use full wave rectification of 50kVDC for 5 seconds without breakdown; Prohibit the use of half wave rectification equipment to avoid misjudgment or damage to the arc extinguishing chamber.

Control circuit insulation test: Use a 500V/1000V insulation resistance meter or 1125VAC withstand voltage test for 1 minute. Before testing, disconnect the charging motor (to avoid damage).

Mechanical/Electrical Operation Inspection:

Mechanical operation: Insert the secondary disconnection simulator, manually charge (about 60 crank operations) until the "closing spring has stored energy", and manually open and close to verify that the status indication is normal.

Electrical operation: Verify the automatic energy storage, opening and closing coil action, and anti pumping function of the charging motor through the control circuit of the testing cabinet or switch cabinet.

(3) Cabinet installation and position switching

Insert into the "test/disconnect" position:

Align the cabinet track, push the circuit breaker into contact with the rack and crank and the cabinet slot, and the anti disengagement lock will automatically engage.

Insert the secondary plug and lock it, install the rack drive fixing component (non arc resistant cabinet), and close the cabinet door.

Switch to the 'Connect' position:

Open the "teardrop shaped" cover plate of the cabinet, insert the dedicated rack handle, rotate clockwise for about 22 turns until the position indicator displays "BREAKER CONNECTED"; When the handle torque reaches 35ft lb, the torque limiter is triggered and the rotation stops.

Extraction process:

Ensure that the circuit breaker is open and the spring is discharged. Rotate the handle counterclockwise to the "test/disconnect" position, unplug the secondary plug, press the anti release lock, and pull the circuit breaker out of the cabinet.

Maintenance process and cycle

(1) Maintenance cycle and basic requirements

Routine maintenance: Every 1000-2000 operations or once a year, the cycle needs to be shortened in harsh environments (high dust, high humidity, corrosive gases).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands