Honeywell Sieger System 57 Modbus Interface Module Kit Operating Instructions

Model: RS422/485 (05701-A-0312), RS232 (05701-A-0313)

Document Number: MAN0502.PM6 Issue 04 October 99 05701M5006

Manufacturer: Honeywell (formerly Zellweger Analytics Limited)

Honeywell Sieger System 57 Modbus Interface Module Kit Operating Instructions

Basic information

Product Name: Sieger System 57 Modbus Interface Module Kit

Model: RS422/485 (05701-A-0312), RS232 (05701-A-0313)

Document Number: MAN0502.PM6 Issue 04 October 99 05701M5006

Manufacturer: Honeywell (formerly Zellweger Analytics Limited)

Safety Warning and Precautions

Warn

This device is not designed or certified for use in hazardous areas.

Suitable for indoor use only.

Avoid exposure to rain or moisture.

Precautions

Only use components and accessories approved by the System 57 control system.

To maintain safety standards, qualified personnel must regularly maintain, calibrate, and operate the System 57 control system.

Important Statement

Zellweger Analytics Limited shall not be liable for any failure to install and/or use the equipment in accordance with the corresponding version and revision of this manual.

The user of the manual should ensure that its content is completely consistent with the equipment to be installed and/or operated. If there are any questions, they should contact the company for consultation.

The company reserves the right to modify the information in this document without notifying any individual or organization.

Glossary

A1: Low or warning alarm level.

A2: Second warning alarm level.

A3: High or primary warning level.

LED: Light Emitting Diode.

LTEL: Long term exposure limit (8-hour time weighted average).

RFI: Radio Frequency Interference.

RH: Relative humidity.

STEL: Short term exposure limit (10 minute time weighted average).

TWA: Time weighted average.

Main functions and overview

Function: Provides digital communication between the System 57 control system and external computer systems, supports reading configuration, alarm status, and executing calibration programs.

Compatibility: Compatible with 5701, 5704, and 5704F control cards.

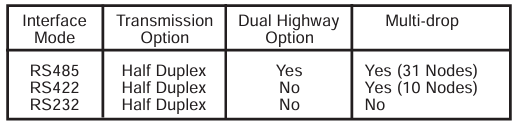

Communication standards: Supports RS485, RS422, and RS232 electrical standards.

Protocol: Operates as a Modbus RTU and supports the 02, 03, 04, 06, and 16 functions of the Modbus protocol.

Data isolation: The data signal is isolated from the System 57 power supply.

Configuration flexibility: Asynchronous serial links can be configured with baud rate, parity, and stop bits.

Way of working

System 57, as a Modbus Remote Terminal Unit (RTU), only transmits data in response to requests from the master device.

The host system (usually a PLC, DCS, or SCADA graphic package) serves as the main device to control the operation of the communication system.

Installation instructions

Preparation before installation

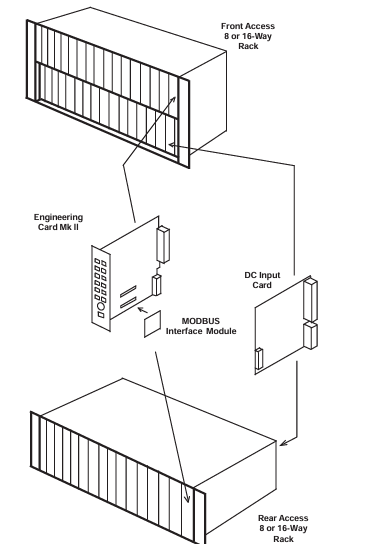

Confirm the type of engineering card, Modbus interface kit can only be installed on Mk 2 engineering cards.

Unpack and inspect the contents of the kit to ensure completeness and no transportation damage.

Installation steps

Cut off all power to the System 57 rack.

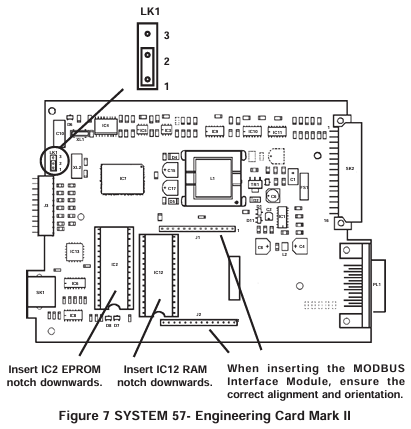

Remove the engineering card, insert the software upgrade EPROM integrated circuit into the IC2 socket of the engineering card, and insert the RAM expansion integrated circuit into the IC12 socket.

Replace the short-circuit link LK1 of the engineering card.

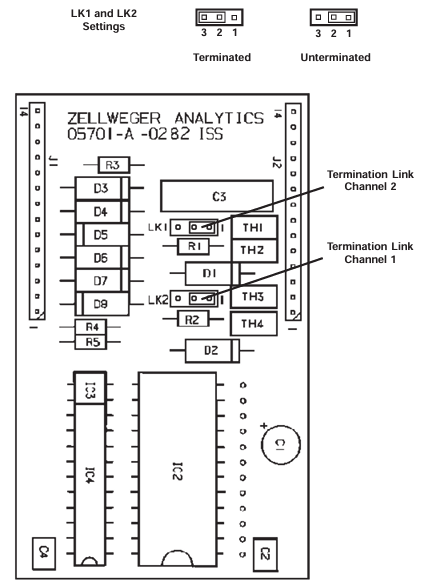

For RS485/422 modules, set the terminal resistance as needed.

Insert the Modbus interface module into the J1 and J2 sockets of the engineering card and reinstall the engineering card.

On site connection

RS485/422 interface: Connect through the auxiliary terminal block TB2 on the DC input card, use shielded twisted pair cable, pay attention to correctly terminating the transmission line, and avoid signal interference.

RS232 interface: also connected through TB2 of DC input card, using high-quality multi-core shielded cable, following the connection specifications of RS232 standard.

Configure Modbus functionality

Host configuration

It is recommended to configure the host to retry at least twice when communication frames are lost.

System 57 configuration

Communication parameters: configurable modes (RS422, RS485, RS232), baud rate, stop bit, parity check, etc.

Address setting: Each rack needs to specify a unique Modbus master address, and when using RS485 half duplex communication and enabling the secondary bus, a secondary address also needs to be set.

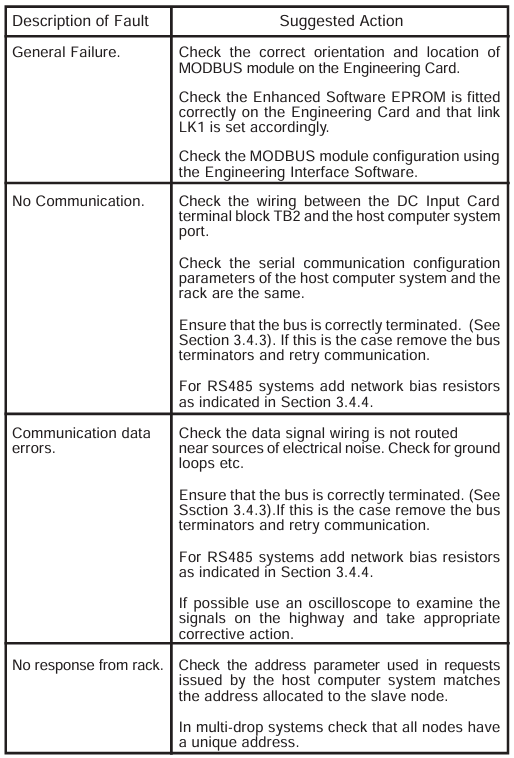

Debugging and Maintenance Instructions

Start program

Ensure that the system power is turned off, reconnect the power, and verify that the LED on the front panel of the engineering card flashes normally and the green POWER ON indicator light remains on.

After the power on suppression time, ensure that the gas detection system operates normally.

Turn on the host system and initiate Modbus master operation.

Simulate alarm conditions, check if the host can correctly detect and take corresponding actions, repeat the test and clear the simulated alarm.

maintenance

The Modbus interface functionality should be regularly tested according to the maintenance procedures in the control system user manual.

Operating instructions

Mainly used to connect gas detection systems to factory control systems, providing centralized monitoring of system status, usually with graphical displays.

The host system needs to be programmed to interpret the signals and status data provided by the System 57 control system.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands