Rockwell Automation SmartGuard 600 Controller

Controller positioning: Programmable Electronic Safety System (PES), supporting 16 digital inputs, 8 digital outputs, 4 test pulse outputs, 1752-L24BBBE with additional support for EtherNet/IP communication;

Safety certification: meets high safety level requirements - IEC 61508 SIL 3, ISO 13849-1 PL (e), EN 954-1 CAT 4, suitable for hazardous environments (North American Class I Div 2 Groups A-D).

Rockwell Automation SmartGuard 600 Controller

Basic and Controller Core Positioning

1. Basic information

Document purpose: To guide the installation, parameter configuration, wiring, and status interpretation of safety controllers, suitable for deployment in industrial safety scenarios such as emergency stop and safety door monitoring;

Controller positioning: Programmable Electronic Safety System (PES), supporting 16 digital inputs, 8 digital outputs, 4 test pulse outputs, 1752-L24BBBE with additional support for EtherNet/IP communication;

Safety certification: meets high safety level requirements - IEC 61508 SIL 3, ISO 13849-1 PL (e), EN 954-1 CAT 4, suitable for hazardous environments (North American Class I Div 2 Groups A-D).

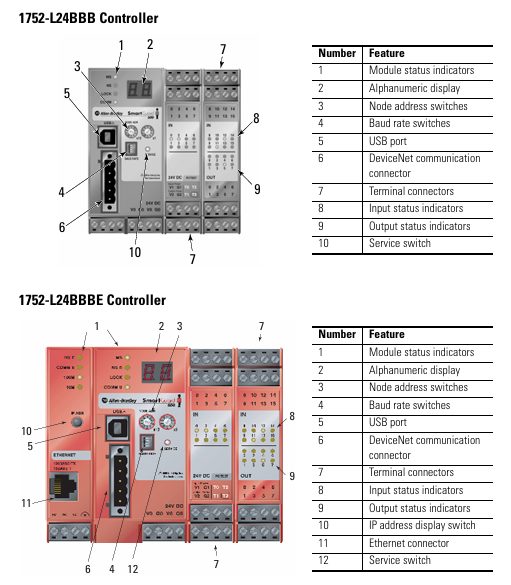

2. Comparison of Model Differences

Model Core Differences Communication Interface Applicable Scenarios

1752-L24BBB Basic Security Control USB+DeviceNet Security Scenarios without Ethernet Requirements (such as Single Device Security Monitoring)

1752-L24BBBE adds Ethernet functionality USB+DeviceNet+EtherNet/IP for distributed security systems that require remote Ethernet monitoring (such as production line level security linkage)

Key configurations before installation (mandatory steps)

1. Safety prerequisite requirements

Precautions for hazardous environments:

It is strictly prohibited to plug and unplug wires with electricity (which may cause arcing and explosion). Power must be cut off or the environment must be confirmed to be in a non hazardous area first;

Prohibition of replacing non original components (which may damage Class I Div 2 compatibility);

Battery replacement is only allowed in non hazardous areas.

Electrostatic protection: Before operation, touch a grounded object to discharge electricity, wear an anti-static wristband, prohibit touching circuit board pins, and store in anti-static packaging when idle.

2. Core parameter configuration (power-off operation)

(1) DeviceNet node address setting

Configuration method: Set through the two rotary switches (ten position+one position) on the front of the controller, with a range of 00~63 (default 63);

Software configuration compatibility: If setting the address through RSNetWorx for DeviceNet software, the rotary switch needs to be turned to 64~99;

Key reminder: Avoid duplicate node addresses, otherwise communication errors may be triggered.

(2) DeviceNet communication rate setting

Default speed: 125 kbps, supports three speeds of 125/250/500 kbps, configured through a 4-digit DIP switch:

DIP switch (1-4) communication rate description

OFF-OFF-OFF-OFF 125 kbps default value

ON-OFF-OFF-OFF 250 kbps medium range networking

OFF-ON-OFF-OFF 500 kbps short distance high throughput scenario

The software configuration of ON-ON-OFF-OFF needs to be set through RSNetWorx

Speed and distance matching: The higher the speed, the shorter the supported cable length (such as 75m for flat cables and 100m for thick cables at 500 kbps), which needs to be selected according to the network size.

(3) EtherNet/IP IP Address Setting (1752-L24BBBE only)

Default mode: BOOTP enabled, IP needs to be allocated through BOOTP server (recommended Rockwell free tool, download link: http://www.ab.com/networks/bootp.html );

Configuration steps:

Run the BOOTP tool and double-click on the device MAC address;

Enter the target IP in the pop-up window and click confirm;

The IP address of the controller can be viewed on the display screen through the front "IP Address Display Switch" (long press for more than 1 second), and error code "n4" indicates abnormal Ethernet configuration.

Controller installation and wiring specifications

1. Physical installation (DIN rail fixation)

Installation requirements:

Only supports EN 50022 standard DIN rails (35x7.5mm or 35x15mm), horizontal installation (vertical installation may affect heat dissipation);

Heat dissipation gap: at least 50mm (2.0in) up and down, and at least 5mm (0.20in) left and right, avoiding installation above heating equipment;

Installation steps:

Hang the top card slot of the controller on the DIN rail;

Press the bottom of the controller and tighten the bottom buckle (1752-L24BBB single buckle, 1752-L24BBBE double buckle);

Install end plates at both ends of the guide rail to ensure stability.

Grounding requirements: Chassis grounding is achieved through DIN rails, which require the use of galvanized yellow chromium steel rails (aluminum/plastic rails may cause poor grounding), and the rails should be fixed every 200mm (7.8in).

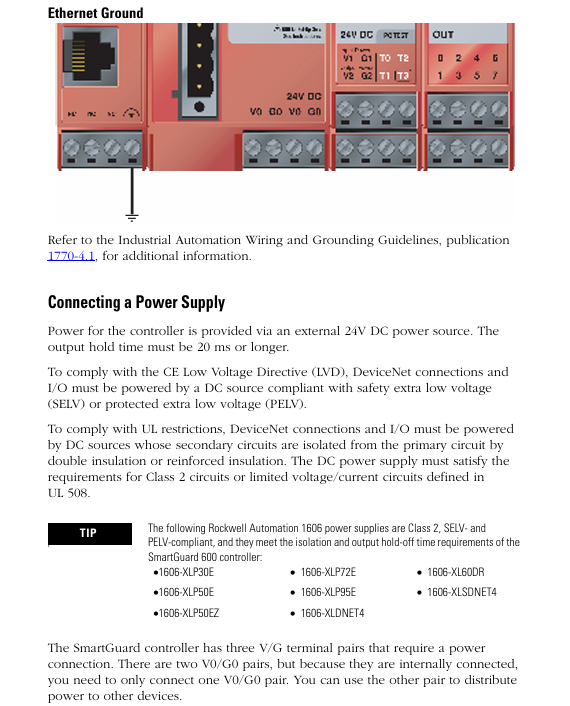

2. Power wiring (safety power supply is the core)

Power specifications:

External power supply: 24V DC (allowable range 20.4~26.4V DC), output holding time ≥ 20ms;

Safety compliance: Must meet SELV/PELV (CE LVD), Class 2 (UL 508), and recommend Rockwell 1606 series power supplies (such as 1606-XLP30E, 1606-XL60DR);

Terminal wiring:

The controller includes 3 sets of V/G terminals (V0/G0: internal logic power supply; V1/G1: Input and test output power supply; V2/G2: Safe output power supply);

The V0/G0 two sets of terminals are internally connected, only one set needs to be connected, and the other set can be used to distribute power to other devices.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands