Allen Bradley 1746-NI8 SLC 500 Analog Input Module

Supplementary example: Multi parameter monitoring

Requirement: Monitor the three-phase motor current (L1-L3), tank pressure, and liquid level, switch the display through a selection switch, and trigger an alarm for low/high liquid level.

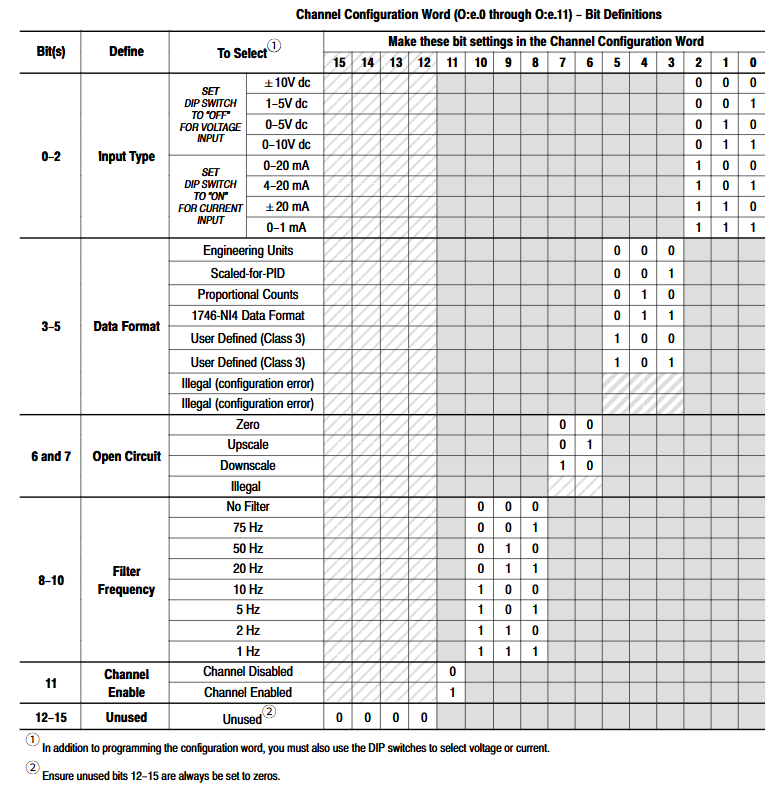

Configuration: Channel 0-2 (4-20mA, current), Channel 3 (4-20mA, pressure), Channel 4 (0-10V DC, liquid level); The ladder program includes scaling, BCD conversion, and alarm logic (trigger light for liquid level<12 inches or>110 inches).

Technical specifications and appendix supplements

Core specifications

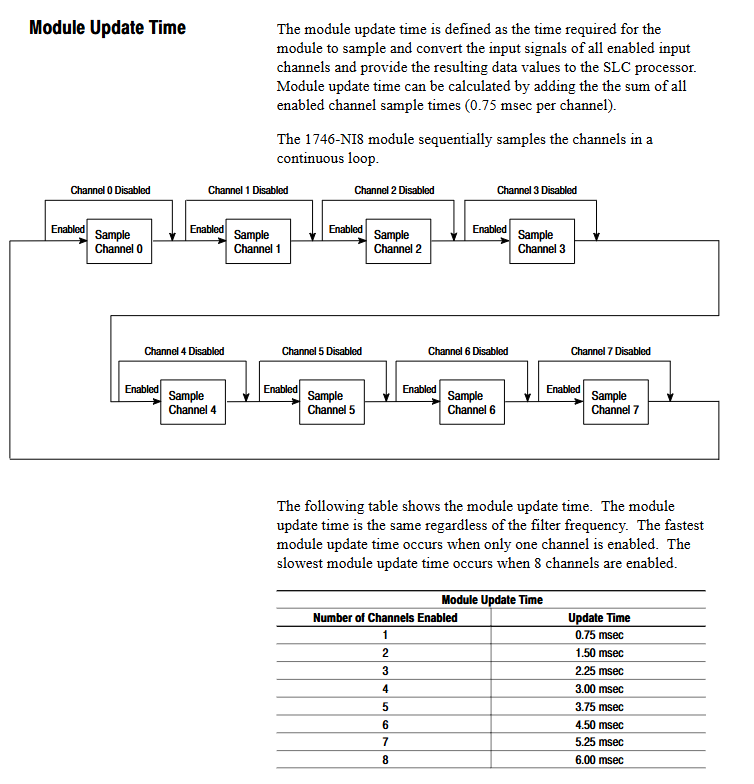

Electrical parameters: A/D conversion to successive approximation type, common mode rejection ratio (CMRR) ≥ 75dB at DC and ≥ 100dB at 50/60Hz, channel update time 0.75m/s channel, total module update time 6ms (8-channel enabled).

Physical parameters: Size 56.6 × 12.1 × 77.5mm (2.23 × 0.48 × 3.05 inches), weight 30.9g (1.09 ounces), terminal supports 2 channels of 14 AWG wires.

Appendix Resources

Appendix A: Complete Electrical/Environmental/Physical Specification Table.

Appendix B: Channel Configuration Worksheet (including bit definition and setting examples).

Appendix C: ID code, address, and configuration word adaptation method for migrating from 1746-NI4 (4-channel) to 1746-NI8.

Appendix D: Binary Supplement Explanation (Explaining SLC Processor Data Storage Format).

Key precautions

Compatibility check: The compatibility of module combinations (refer to Table 3-2 in the manual) needs to be confirmed for the 2-slot expansion chassis (1746-A2), and some combinations require external power supply; The programming software needs to support Class 3 mode (such as RSLogix 500 V1.30+).

Anti interference measures: The distance between the analog line and the power line should be ≥ 15cm, shielded twisted pair cables should be used, and the shielding layer should be grounded at one end; Choose an appropriate filtering frequency (such as 10Hz filtering in a 60Hz environment) to reduce power frequency noise.

Safety regulations: Installation/disassembly/wiring must be powered off, hazardous environments (such as Class I Zone 2) must meet explosion-proof requirements, module grounding relies on DIN rails (recommended galvanized steel rails), fixed every 200mm.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands