Allen Bradley 1747-DCM Direct Communication Module

Allen Bradley 1747-DCM Direct Communication Module

Core framework and scope of application

The document follows the logical mainline of "safety specifications → system positioning → hardware configuration → installation and operation → fault handling", covering the entire process of module configuration from early stage to later stage maintenance. The applicable product is the 1747-DCM direct communication module, which serves as the communication interface module for SLC 500 series controllers (including extended chassis or modular controllers). It is connected to higher-level Allen Bradley controllers (such as PLC-2/3/5, SLC with RIO scanner) through RIO (Remote I/O) links to achieve data transmission between distributed processors, and is suitable for multi controller collaboration scenarios in industrial automation (such as multi area data exchange in production lines and remote device monitoring).

Core content sorting

(1) System positioning and hardware characteristics

Module core functions

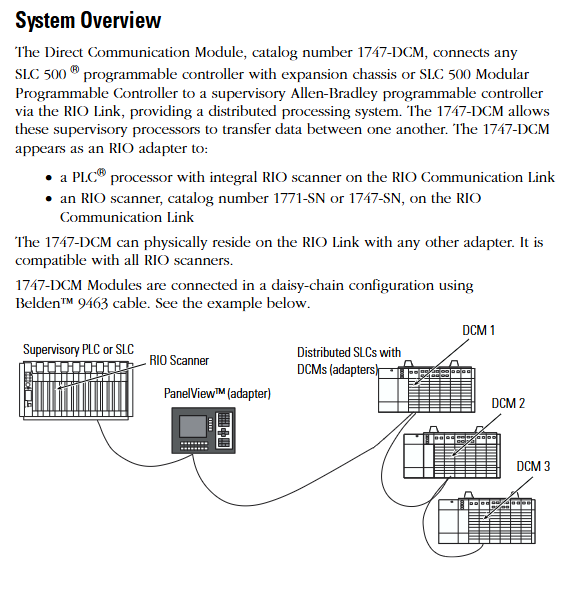

Communication bridge function: manifested as an RIO adapter on the RIO link, it supports communication with PLC processors (such as PLC-5/250) or independent RIO scanners (1771-SN, 1747-SN) with integrated RIO scanners, enabling bidirectional data transmission between the upper level controller and the distributed SLC 500 controller.

Expansion node capability: Supports expansion node functionality. If all scanners and adapters on the RIO link have this capability, up to 32 adapters can be connected. At full baud rate, 82 Ω terminal resistors (1/2W) need to be connected at both ends of the link to ensure signal integrity.

Hardware structure and key components

Physical components: including self-locking buckle (fixing module to chassis), 2 sets of DIP switches (configuration parameters), 2 status LEDs (red FAULT light, green COMM light), RIO link connector (front end), cable fixing slot, side label (module information), door label (parameter identification). The module is a full-size circuit board and needs to be installed in the non-zero slot of SLC 500 chassis (slot 0 reserved for CPU).

Status LED function:

FAULT light (red): Always on indicates an internal fault, flashing indicates a configuration error, and off indicates normal operation.

COMM light (green): Always on indicates normal communication, flashing indicates that the upper level processor is in programming/testing/fault mode, and off indicates communication interruption (such as scanner not connected or link failure).

(2) Module configuration: DIP switch parameter setting

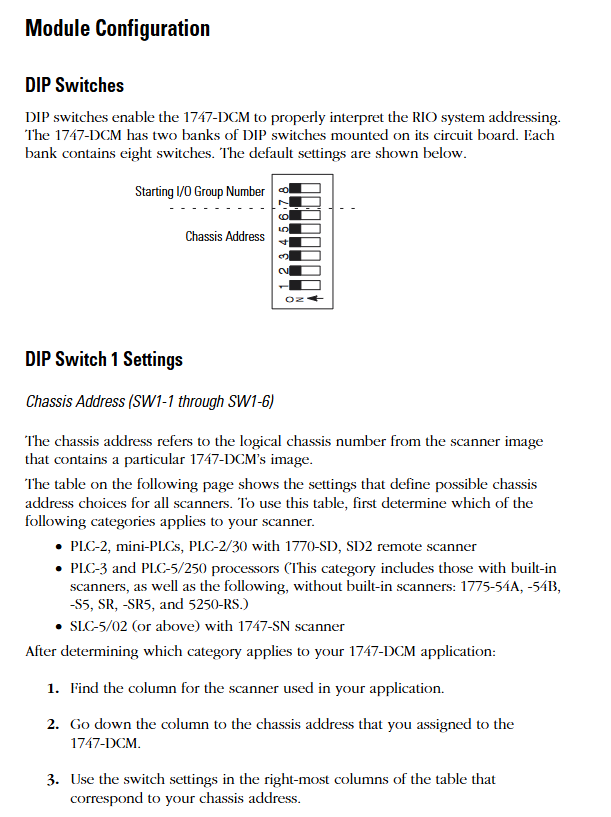

The 1747-DCM contains 2 sets of 8-bit DIP switches (SW1, SW2), which need to be configured before installation. The key parameters are as follows:

1. SW1 (chassis address and starting I/O group)

Rules for configuring switch position functions

SW1-1~SW1-6 logical chassis addresses correspond to the chassis number (octal) of the higher-level scanner. The switch status needs to be selected according to the scanner type (PLC-2/3/5, 1747-SN). For example, chassis address 1 of PLC-5/250 corresponds to SW1-1~5 being ON and SW1-6 being OFF

The starting I/O group numbers for SW1-7~SW1-8 only support even numbers (0/2/4/6) and need to match the chassis size:

-0 (ON+ON): Suitable for all sizes

-2 (ON+OFF): Suitable for 3/4, 1/2, and 1/4 sizes

-4 (OFF+ON): Suitable for 1/2 and 1/4 sizes

-6 (OFF+OFF): Only compatible with 1/4 size

2. SW2 (data rate, fault handling, chassis attributes)

Rules for configuring switch position functions

SW2-1~SW2-2 data rates support three baud rates, which need to be consistent with the RIO link:

-57.6K baud (ON+ON): Maximum cable length 3048m (Belden 9463)

-115.2K baud (ON+OFF): Maximum 1524m

-230.4K baud (OFF+ON): maximum 762m

-Disable (OFF+OFF): Do not enable communication

When SW2-3 fault occurs, clear all data bits in the input image table (status bits are retained) - OFF: When there is a communication fault with RIO or when the upper level processor enters fault mode, clear all data bits in the input image table

-ON: Maintain the last state of the data bit in case of malfunction (confirm that there is no safety risk)

SW2-4 Last chassis identifier - OFF: The module shares logical chassis with other adapters and is the device with the highest I/O group number in the chassis

-ON: Not the last chassis device

SW2-5~SW2-6 logical chassis size allocation allocates the image space of modules in the scanner, determining the number of data transmission words:

-1/4 size (ON+ON): 1 status word+1 data word (2 words in total)

-1/2 size (ON+OFF): 1 status word+3 data words (4 words in total)

-3/4 size (OFF+ON): 1 status word+5 data words (a total of 6 words)

-Full size (OFF+OFF): 1 status word+7 data words (a total of 8 words)

Key note: Module images cannot cross logical chassis boundaries. For example, selecting the starting I/O group 6 while configuring as 1/2 size will trigger a configuration error.

(3) Installation and wiring: practical operation specifications

Pre-installation preparation

Power requirements: Power is obtained through the SLC 500 chassis backplane, requiring a current of+5V DC/360mA. Before installation, the remaining capacity of the chassis power supply needs to be confirmed; The fixed SLC 500 controller's 2-slot expansion chassis only supports one 1747-DCM and requires reference to the 1746-2.35 manual to confirm compatibility with other I/O modules.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands